- +86-13775339109

- Jessica@nq-fiberglass.cn

- No 61 Fangxian, Danyang, Jiangsu

Table of Contents

ToggleCarbon fiber is celebrated for its incredible strength-to-weight ratio—but what about carbon fiber conductivity? If you’re asking, “Is carbon fiber conductive?”, you’re not alone. Whether you’re designing for aerospace, automotive, electronics, or industrial use, understanding the electrical conductivity of carbon fiber and its thermal performance is critical to getting your materials right.

In this guide, you’ll learn how carbon fiber conducts electricity and heat, how it compares to metals like copper and aluminum, and how these properties affect real-world carbon fiber applications—from EM shielding to structural components.

The carbon fiber material derives its properties from a graphitic structure, where carbon atoms form hexagonal patterns that facilitate electron movement. While it exhibits some electrical conductivity, this is lower than that of metals like copper. Notably, this conductivity is anisotropic—stronger along the fiber axis and significantly weaker across the weave or through the resin.

Carbon fiber is often described as a semi-conductor or anisotropic conductor. Its conductivity depends on several factors, including fiber orientation, weave style, and the type of resin used.

Electron Flow: Electrons travel more easily along the fiber’s length than across the weave or through the surrounding resin.

Surface vs. Through-Thickness Conductivity: Surface conductivity refers to current flowing along exposed fibers. In contrast, through-thickness conductivity is limited due to non-conductive resin layers between fiber sheets.

Carbon fiber composites, known for their lightweight properties, can effectively block or reflect electromagnetic interference in electronic housings and enclosures.

Grounding Components: In aerospace and electric vehicles, carbon fiber is used for safely dissipating static electricity.

In advanced designs, carbon fiber can serve dual functions—offering structural integrity while also enabling conductivity in embedded electronics or sensors.

While not as thermally conductive as metals, carbon fiber offers moderate thermal conductivity—significantly higher than that of polymers or fiberglass. This makes it ideal for use in applications requiring heat resistance and thermal management.

High-Temperature Environments: Carbon fiber maintains performance in aerospace, motorsport, and industrial settings where heat is a concern.

Heat Spreading: Used in composite enclosures and panels to prevent localized overheating in electronics or battery systems.

High-Modulus Carbon Fiber: Certain pitch-based carbon fibers exhibit exceptionally high thermal conductivity, in some cases approaching that of metals.

Carbon fiber stands out among structural materials for its anisotropic conductivity, high strength, and low weight. While not as conductive as copper or aluminum, it offers enough electrical conductivity for uses like EMI shielding, conductive composites, and lightweight enclosures. Compared to fiberglass, carbon fiber composites are much more conductive and rigid, making them ideal for aerospace, automotive, and electronics applications where both strength and conductivity are critical.

Property | Carbon Fiber | Copper | Aluminum | Fiberglass |

Electrical Conductivity | Moderate (anisotropic) | Very High | High | Very Low |

Thermal Conductivity | Moderate | Very High | High | Low |

Density (g/cm³) | ~1.6 | 8.96 | 2.70 | ~2.5 |

Tensile Strength (MPa) | 3,500 – 6,000 | ~210 | ~90 | 345 – 1,300 |

Stiffness (GPa) | 200 – 700 | ~110 | ~70 | 70 – 90 |

Corrosion Resistance | High | Low | Moderate | High |

Applications | Aerospace, EMI shielding, sporting goods | Electrical wiring, electronics | Aircraft structures, heat sinks | Insulation, boat hulls, panels |

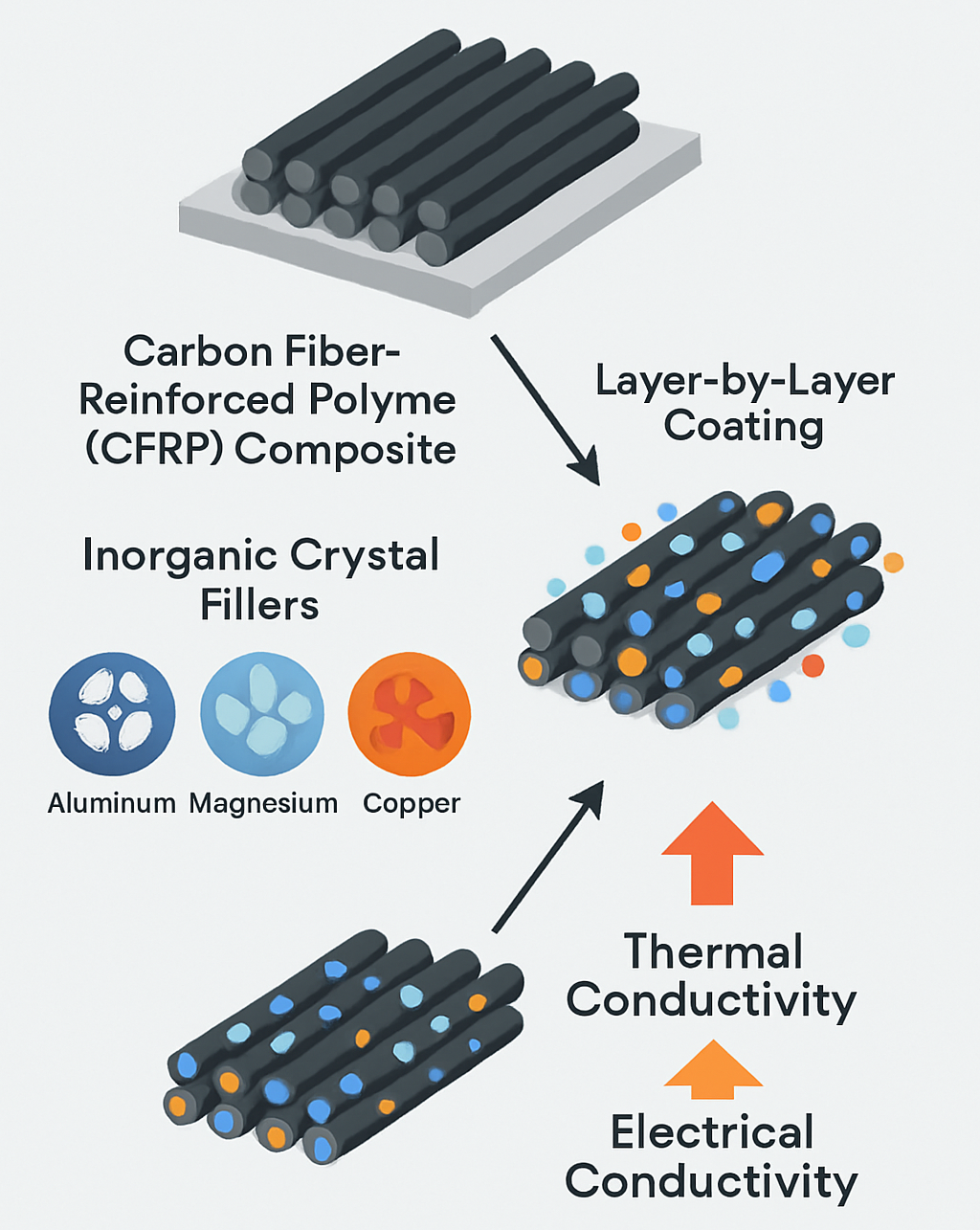

The electrical conductivity of carbon fiber composites can be tailored based on application needs. This is achieved by modifying the fiber type, resin system, and structural layout.

The future of conductive carbon fiber is exciting. Here’s where things are headed:

Smart Structures: Using carbon fiber as sensors or antennae in aircraft or infrastructure.

Energy Storage: Carbon fiber composites are being developed for structural batteries—where the material holds energy.

3D Printed Carbon Fiber Composites: New additive manufacturing techniques allow you to print conductive parts with embedded circuits.

Hybrid Materials: Combining carbon fiber with carbon nanotubes, graphene, or metallic fibers for ultra-high conductivity and mechanical strength.

As technology progresses, you’ll see carbon fiber being used in more than just frames—it will be active, responsive, and electrically functional.

Now that you understand the thermal and electrical conductivity of carbon fiber, you’re better equipped to choose the right materials for your next project. While it’s not as conductive as metal, carbon fiber offers the ideal mix of lightweight strength and functional conductivity for EMI shielding, heat management, and structural applications.

Want to learn more about carbon fiber types or how it’s used? Explore our related guides for deeper insights.Contact us for project support or material recommendations.

Connect with an NQ expert to discuss your product needs and get started on your project.

Yes, carbon fiber conducts electricity, particularly along the directional fibers, although its conductivity is lower than that of metals.

Yes. If conductive carbon fiber touches a live circuit, it can cause a short. Always use insulation or protective coatings near carbon fiber products.

Graphite, a form of carbon, is a good conductor due to its free electrons, while carbon fiber, particularly the conductive carbon fiber, shares some of this behavior but is less conductive.

Not in a way that shocks you. But it can conduct current if in contact with a power source—handle with care in live systems.

Diamond conducts heat extremely well but is a poor electrical conductor due to its composite structure and lack of free electrons.

Steel is significantly more conductive than carbon fiber materials; however, carbon fiber conduct electricity while being much lighter and more corrosion-resistant.

Carbon can be either a good conductor or an insulator, depending on its form. Carbon fiber, a composite material, is a semi-conductor, meaning it conducts electricity but not as much as metals.