- +86-13775339109

- Jessica@nq-fiberglass.cn

- No 61 Fangxian, Danyang, Jiangsu

Table of Contents

ToggleCarbon fiber is known for being incredibly strong and surprisingly light—but how strong is it, really? From aerospace components to high-end sports equipment, carbon fiber has earned its reputation as a high-performance material. Its strength-to-weight ratio surpasses that of steel and aluminum, making it ideal for applications where both durability and reduced weight matter.

In this article, we’ll explore what gives carbon fiber its remarkable strength, how it compares to other materials, and why it’s become a go-to choice in industries pushing the limits of performance.

Carbon fiber is a high-performance material composed of tightly bonded carbon atoms arranged in a microscopic crystalline structure. This atomic arrangement gives it exceptional strength and rigidity. The basic units—carbon filaments—are incredibly thin (finer than a human hair) yet remarkably strong, with tensile strengths exceeding 500,000 psi (≈3,500 MPa).

To make carbon fiber usable, thousands of these filaments are bundled into “tows,” woven into fabrics, and combined with resins such as epoxy to form a composite. The result is a lightweight, durable material that resists fatigue, corrosion, and heat—ideal for aerospace, automotive, sports equipment, and more.

What makes carbon fiber especially impressive is its strength-to-weight ratio, which far surpasses that of steel or aluminum. Despite its lightness, it maintains excellent stiffness, making it one of the strongest and most versatile materials used in high-performance industries today.

Carbon fiber isn’t just strong—it’s engineered to outperform traditional materials like steel and aluminum. If you’re wondering why, it starts at the smallest level: the structure of a carbon atom.

Carbon fiber is part science, part craft Our engineers and manufacturers select every detail, fiber to fabrication, to achieve the optimal mix of strength, weight and durability. Every step — from harvesting the fiber to the final cure — forms the character of how the final product will perform under load.

When working with carbon fiber, your first major decision is choosing the right type of fiber. Standard modulus fibers offer a balance of strength and flexibility—perfect for projects that need durability with some give. On the other hand, high modulus fibers deliver greater stiffness, which is ideal for high-performance builds, but they can be more brittle under certain conditions.

Your choice should depend on your end use. If you’re designing aerospace parts or sports cars, stiffness and minimal flex matter—so high modulus carbon fiber is the right fit. If you’re developing consumer electronics or products that need some flexibility, standard modulus fibers might be a better match.

What makes carbon fiber so effective is how the fibers behave under stress. With tensile strengths reaching up to 500,000 psi, you can push boundaries while keeping weight to a minimum. To get the performance you need, you’ll have to match fiber characteristics to your project goals. That’s why manufacturers test different fiber types and align them with your specific design requirements.

When you work with carbon fiber, the resin matrix plays a crucial role. It’s what binds the fibers together, spreads the load, and adds overall toughness to the composite. Without the right resin, even the strongest fiber won’t perform as expected.

You’ll most often use epoxy resin, known for its excellent adhesion, durability, and resistance to wear. But depending on your budget or performance needs, you might consider polyester or vinyl ester resins. These alternatives can lower costs or meet specific chemical or environmental requirements.

The key is compatibility—your resin must match your fiber and your application. New technologies, like toughened epoxies and bio-based resins, are also emerging. They offer improved strength, impact resistance, and sustainability, giving you more flexibility in design without compromising performance.

By choosing the right resin system, you ensure your carbon fiber component is not just strong, but built to last under real-world conditions.

The way you weave carbon fiber dramatically changes how it performs.

A plain weave gives you a balanced, clean look—but it trades some strength for appearance.

A twill weave is more flexible and easier to drape, making it ideal for curved surfaces and complex shapes.

Unidirectional fabric, where all fibers run in the same direction, offers maximum strength along one axis—much like a bundle of aligned rods. However, it has lower strength across other directions.

To get multi-directional strength, you can layer different weaves at angles—often 0°, 45°, or 90°. This allows your part to resist stress from different directions.

That’s why high-performance bikes, aerospace components, and race cars often use a combination of weaves—balancing strength, flexibility, and visual appeal.

Layup refers to how you arrange the layers of carbon fiber to shape performance. Each layer—often just 0.25 mm thick—adds to the final strength, stiffness, and weight of the part. If you’re aiming for strength in one direction, go with unidirectional layups—they concentrate force where you need it most. Want a more balanced structure? Use woven layups, or stack layers at different angles—0°, 45°, 90°—to control how the part flexes and resists loads from all sides. Precision is critical. A misaligned layer or trapped air bubble can weaken the entire part.

You’ll commonly use one of three methods:

Prepreg layup – uses resin-infused fabric and requires controlled curing.

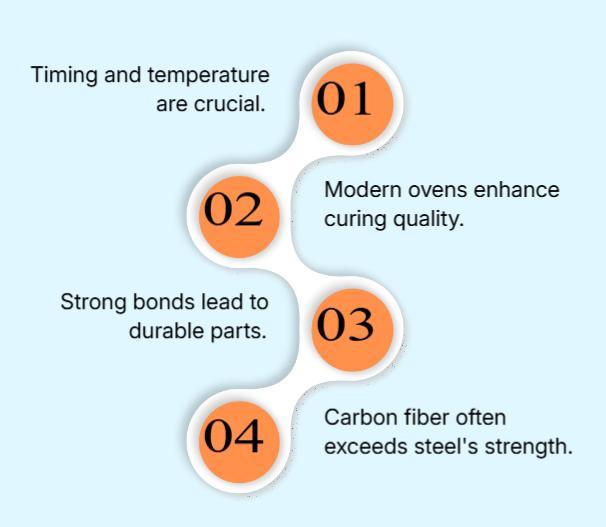

Curing is the final step where your carbon fiber part gains its full strength and form. By applying high heat and pressure, the resin bonds tightly with the fibers, turning multiple layers into a single, solid composite. If curing time is too short or the temperature too low, the part remains weak and vulnerable to failure. That’s why precision matters. With today’s advanced ovens and autoclaves, you can cure parts more evenly and efficiently, minimizing air bubbles and weak spots. When done correctly, the result is a component that’s not only light but also incredibly strong—sometimes stronger than steel at just a quarter of the weight.

Industries using carbon fiber’s performance ratio include:

Electronics (lightweight, strong casings)

Carbon fiber is an incredibly strong and light material that’s become ubiquitous in a number of different industries. Its high tensile strength, low weight and strong resistance to corrosion distinguish it from steel, aluminum and titanium. Here’s a quick look at how carbon fiber stacks up against these metals:

Property | Carbon Fiber | Steel | Aluminum | Titanium |

Tensile Strength (MPa) | ~3447 | ~400–2500 | ~90–570 | ~900 |

Density (g/cm³) | 1.6 | 7.85 | 2.7 | 4.5 |

Modulus of Elasticity (GPa) | 70–294 | ~200 | ~70 | ~116 |

Corrosion Resistance | Excellent | Poor | Good | Excellent |

Thermal Conductivity (W/m·K) | 5–10 | 45–60 | 205 | 21.9 |

Carbon fiber’s lightweight and strength make it a popular choice for aerospace, sports equipment, and automobiles, where every saved ounce counts. Traditional metals such as steel and aluminum fail in these areas, particularly when weight and corrosion are a concern. Numerous industries have since opted for carbon fiber for components that must endure and maintain low weight.

Carbon fiber is much stiffer than steel, with high-modulus types being up to 1.5 times as stiff. It’s only one-fifth the weight of steel. That means parts made from carbon fiber can be both lighter and stiffer, so they increase speed and fuel savings in cars, bikes, and planes. Even steel, while durable, cannot attain this balance. By replacing traditional metals with carbon fiber, it can result in significant weight reductions in construction and manufacturing facilitating easier transportation and energy savings.

Carbon fiber is many times stronger than aluminum. It is lighter. That’s why it’s used for planes, racing bikes and expensive cars. In these locations, shedding even a bit of weight really counts.

All sorts of industries that need to reduce weight but maintain strength are turning away from aluminum and toward carbon fiber. Today, it dominates in drone frames, wind turbine blades and elite sporting goods.

Titanium is strong and doesn’t rust, but it’s heavier than carbon fiber. Carbon fiber manages long-term stress better on account of its high fatigue resistance. It’s cheaper to produce big carbon fiber components than titanium ones. Industries such as aerospace and medical devices have long used carbon fiber in lieu of titanium when requiring lightweight, strong and low-cost materials.

Carbon fiber gives you the best of both worlds—high strength and low weight. From cars to planes to performance gear, it’s trusted where strength matters and every gram counts.As more industries look to build smarter and lighter, carbon fiber is leading the way. Ready to see what it can do for your project? Explore, test, and innovate—this material is built for the future.

If you have questions or want to discuss your project, feel free to contact us via WhatsApp +86-13775339109, WeChat 13775339100, or email fiberglassmesh@hotmail.com. We’re here to assist you!

Connect with an NQ expert to discuss your product needs and get started on your project.