HEMC Hydroxyethyl Methyl Cellulose

Features

HEMC is a high-performance non-ionic soluble polymer that is odorless, tasteless and non-toxic. It appears as a white or slightly yellow powder that can dissolve in cold water to form a transparent viscous solution. It has a variety of properties such as thickening, viscosity increasing, moisturizing, dispersing, emulsifying, and wetting, and is widely used as construction materials, coatings materials, medicine materials, cellulose food, petrochemical materials,etc.

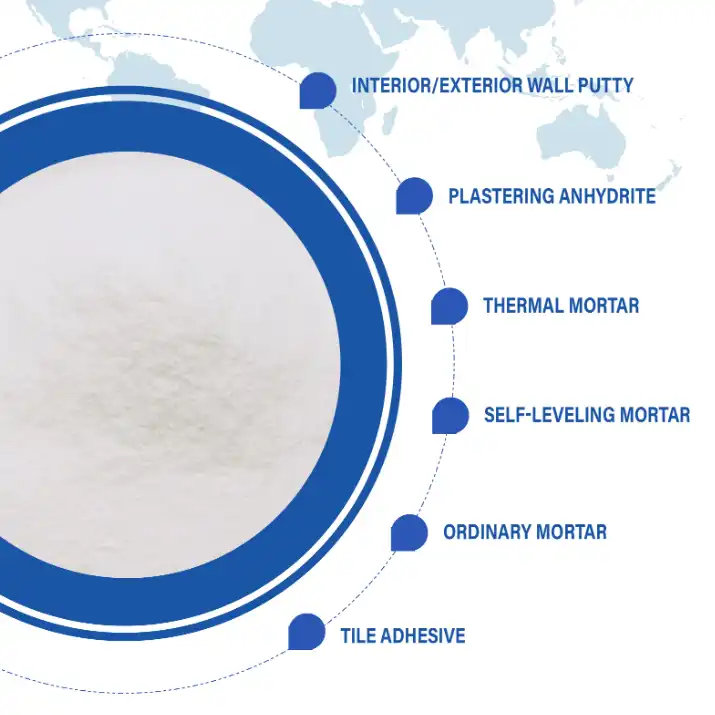

Market Prospects

With the continuous development of the global economy and the increasing demand for high-quality chemicals in various industries, the market demand for HEMC will continue to grow. With the continuous advancement of science and technology, our HEMC production technology and product quality will be further improved. Through technological innovation and product upgrades, the performance of HEMC will be even better and the application field will be further expanded. This will bring new growth points and opportunities to the HEMC market.

Hydroxypropyl Methyl Cellulose Manufacturing Process

As a cellulose factory,we select high-quality cellulose and chemical additives, and perform pretreatment to optimize reaction conditions. Under a controlled environment, cellulose is etherified with specific chemical reagents to form the HEMC structure of cellulose. After the reaction, neutralization treatment is performed to remove excess chemical reagents, and product purity is ensured through multiple washings. The product is dried to an appropriate moisture content and then crushed to the required particle size to ensure product uniformity. Strict testing is performed on various performance indicators of HEMC, including viscosity, purity, pH value, etc., to ensure compliance with standards. Professional packaging materials are used to protect the product from external environmental influences and store it safely.

Use Precautions

1 The optimal concentration of HEMC in different applications is different. Please be sure to weigh it accurately according to the specific application scenario and formulation requirements, and fully dissolve it under the recommended temperature and stirring conditions to avoid agglomeration or incomplete dissolution affecting the use effect.

2 The performance of HEMC is affected to a certain extent by the pH value of the system. Before use, please confirm and adjust the pH value of the working solution to the appropriate range to ensure the stability and performance of HEMC.

3 High temperature may cause degradation or performance degradation of HEMC, while low temperature may affect its dissolution rate. Therefore, extreme temperatures should be avoided as much as possible during storage, transportation and use, and kept within the recommended temperature range.

4 In a multi-component system, the order of adding HEMC has an important influence on the performance of the final product. It is generally recommended to add HEMC after the other solid components are dissolved, and sprinkle it slowly and evenly, while maintaining good stirring to prevent agglomeration.

5 Before using HEMC, its compatibility with other components in the system (such as electrolytes, surfactants, organic solvents, etc.) should be evaluated to avoid precipitation, stratification or performance loss due to incompatibility.

6 HEMC should be stored in a dry, cool, well-ventilated place, away from direct sunlight and high temperature, and keep the packaging sealed to prevent moisture and contamination.

7 Although HEMC is generally considered to be of low toxicity, it still needs to be used in accordance with chemical safety operating procedures, wear appropriate personal protective equipment such as dust masks, gloves, etc., and avoid direct contact with the skin and inhalation.

●FREE SAMPLE

*Customization is always available, please mark down your need in cart or just contact us.

Project Monitoring

Shipping Order Track

Instructions for Use

VIP Customer Service

Intact Guarantee

Characteristics

- Excellent Water Dolubility:

- Hydroxyethyl groups are introduced into the HEMC molecule. These groups enhance the interaction between the molecule and water molecules, allowing HEMC to quickly dissolve in cold water to form a clear, transparent viscous solution.

- Broad PH Stability:

- The non-ionic nature of EMC’s molecular structure makes it less susceptible to solution pH. HEMC maintains the stability of its performance over a wide pH range (typically pH 2-12).

- Excellent Thickening And Suspending Ability:

- HEMC molecular chain is long and soft, and can form a complex network structure in water. This network structure is able to capture and immobilize a large number of water molecules, thereby significantly increasing the viscosity of the solution. At the same time, the gaps in the network structure can also effectively suspend solid particles and prevent them from settling.

- Good Thermal Stability:

- The chemical bonds in HEMC molecules are relatively stable and not easily broken by heat. Therefore, HEMC maintains the integrity of its molecular structure even at higher temperatures, thus keeping its performance stable.

Main Function

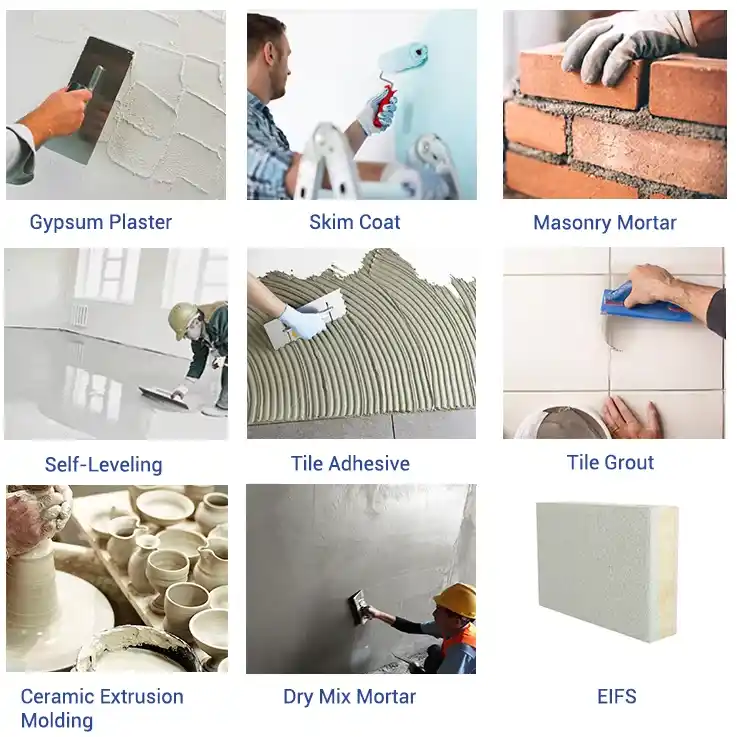

- Construction Industry:

- HEMC is an ideal additive for cement mortar, used to improve the working performance and physical and mechanical properties of mortar. It can significantly improve the water retention, adhesion, strength, crack resistance, impermeability and freeze-thaw resistance of mortar. At the same time, the opening time of the mortar is extended and the construction efficiency is improved.

- Coating Industry:

- EMC is widely used in various coatings as a thickener, suspending agent and stabilizer. It can improve the viscosity, stability, brushability and leveling properties of paint. Enhance the adhesion and water resistance of paint, making the coating more uniform and smooth.

- Pharmaceutical Industry:

- EMC can be used as a binder, disintegrant, coating material, etc. for tablets in the pharmaceutical field. Can improve the taste, stability and release characteristics of drugs. Improve the hardness and disintegration speed of tablets to ensure that the active ingredients of the drug can be released evenly.

- Food industry:

- HEMC is used in the food industry as a thickener, stabilizer, emulsifier, etc., and is widely used in ice cream, bread, cakes and other foods. It can improve the water retention and taste of food, making the food more delicate and soft. At the same time, it extends the shelf life of food and maintains its freshness and flavor.

- Other Industries:

- HEMC is also widely used in petroleum, daily chemicals, textiles, papermaking, leather, ink, plastics, rubber and other fields. It can be used as thickener, dispersant, stabilizer, etc. to improve product quality and performance. Meet the specific needs of different fields and provide customers with customized solutions.

Appearance | White or yellowish powder |

Methoxy content /% | 19.0-26.0 |

Hydroxyethoxy content /% | 4.0-16.0 |

Purity | 99% |

Fineness/% | 80 mesh sieve residue≤8.0 |

Dry weight loss rate /% | ≤6.0 |

Ash/% | ≤6.0 |

Moisture | ≤5% |

Viscosity /MPa·S | 100.0 – 80000.0 (annotated value±20%) |

PH value | 5.0-9.0 |

Light transmittance /% | ≥80 |

Classification | Chemical Auxiliary Agent |

Packing Density | 300 – 600g/l |

Particle Size | 100% pass 80 mesh |

Water retention | ≥95% |

Grade | Industrial Grade |

Gel temperature /℃ | ≥75.0 |

Place of Origin | Jiangsu |

HOT SELLING CELLULOSE SERIES

CELLULOSE MANUFACTURERS & SUPPLIERS

NQ is an influential cellulose ether manufacturer in China. We are committed to the research, development, production and sales of hpmc, hemc and hec. High-quality products and first-class services make us do better!

We providing high-quality and best cellulose ether price for many countries and region.

✅️ 16 years of global production and sales experience;

✅️ Cellulose Ether Factory in China, complete supply chain system;

✅️ Cellulose ether annual production capacity of 50,000, to provide a stable supply, fast delivery;

✅️ 98.2% customer satisfaction, NQ professional team do our best to meet your needs.