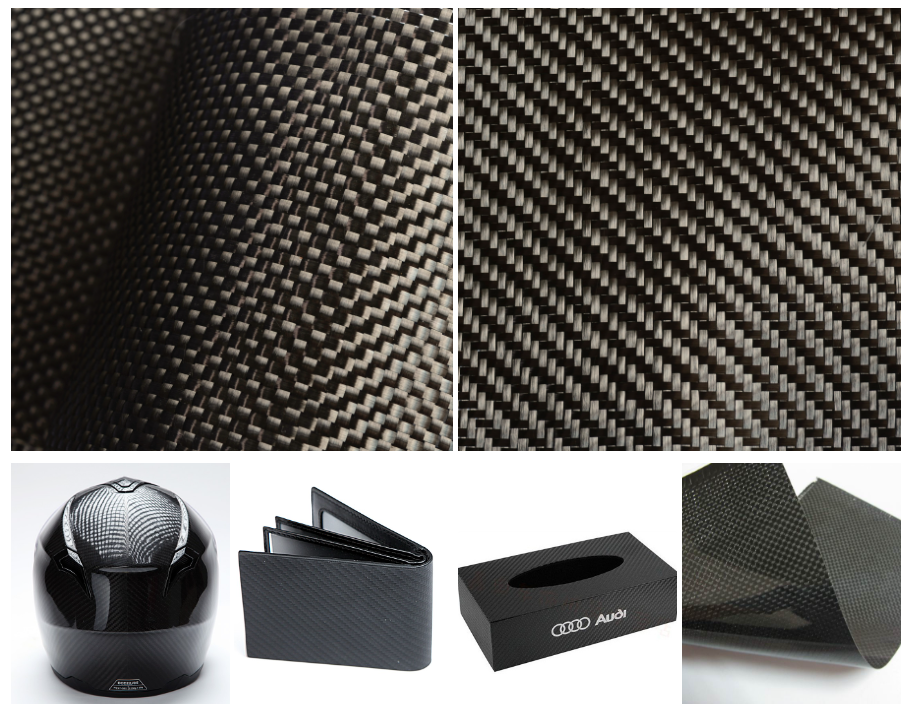

1. High Strength and Stiffness: Carbon fibers are inherently strong and stiff, and the bi-directional braided structure allows the fibers to be more tightly aligned, providing even higher strength and stiffness.

2. Uniformity and controllability: Through the braiding process, the carbon fibers are more evenly distributed in the fabric, thus ensuring uniformity and controllability of the material.

3. Good corrosion resistance: Carbon fiber has good corrosion resistance and can resist the erosion of acid, alkali and other chemicals, which is suitable for applications in various harsh environments.

4. Easy molding: Since carbon fiber bi-oriented woven fabrics have already formed a predetermined composite structure, they can be formed into various shapes with simple manufacturing processes such as hot pressing or vacuum molding.

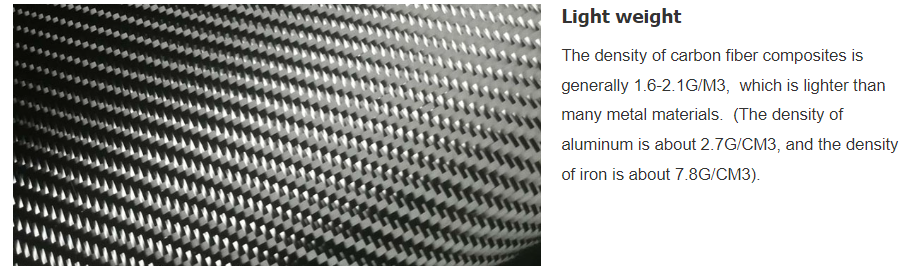

5. Lightweight: Carbon fiber bi-oriented woven fabric is lightweight, which reduces the weight of the structure and improves power density and energy efficiency compared to metal materials of the same strength.

6. Good abrasion resistance and durability: Because carbon fiber has good abrasion resistance and durability, products made of carbon fiber biaxially braided fabric can be used for a long time in harsh environments.

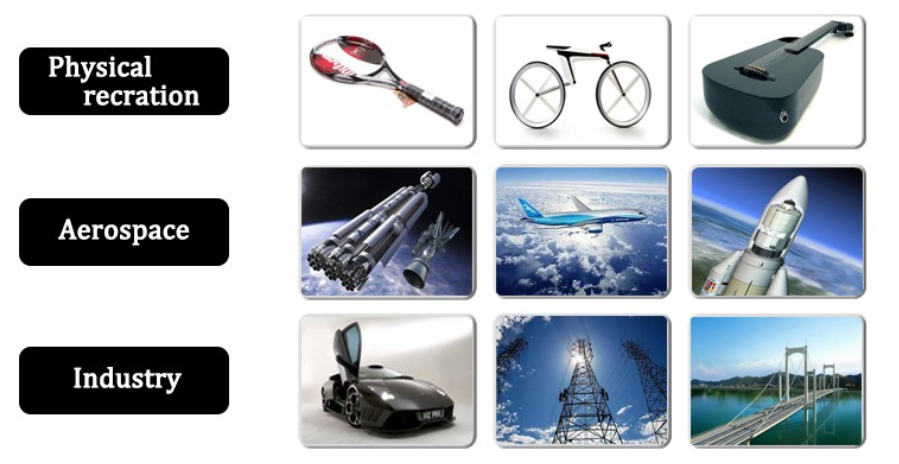

7. In short, carbon fiber bi-directional braided fabric has the advantages of high strength and stiffness, uniformity and controllability, good corrosion resistance, easy molding, light weight, and good abrasion resistance and durability. These abilities make Carbon Fiber Bi-Directional Braided Fabric widely used in the manufacturing of aerospace, automotive, sports equipment, construction and other fields.