This product is very good. I'm very satisfied with it

Alexander BajoMANAGE

Great supplier, they coommunicated effectively and provided an exceptional product. thanks so much!!!

Andy FerrariManager

Application:Environmental protection project,Heating product

Technique:Wet forming

Place of Origin:Jiangsu, China

Brand Name:henglv

Model Number:S-CT7-50

Processing Service:Bending, Decoiling, Cutting

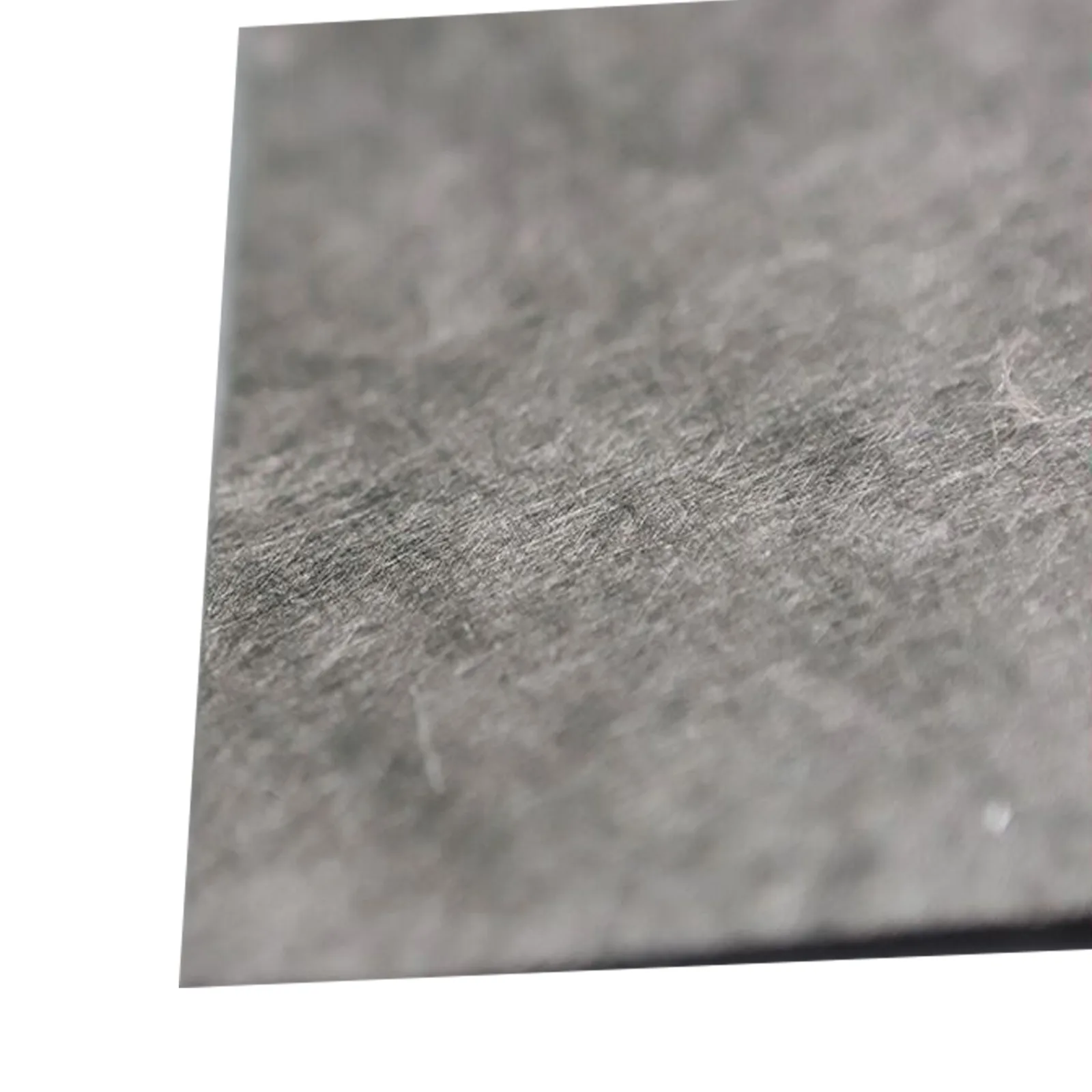

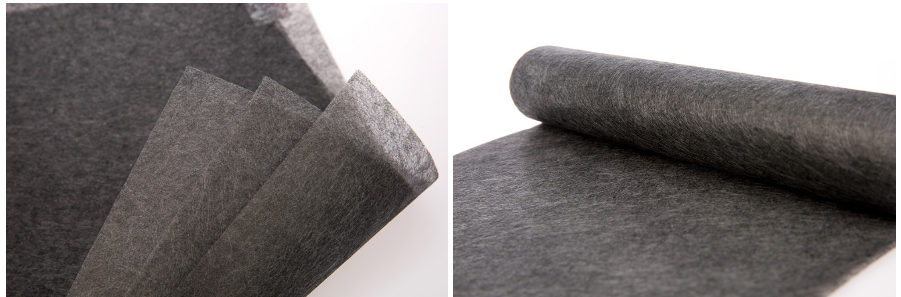

Material:Fibreglass

Package Type:Inner packing: shrink packing or plastic bag. Outer packing: 24 rolls or 54 rolls or 72 rolls/carton.

Supply Ability:8000000 Square Meter/Square Meters per Month

1. High Strength and Stiffness: Carbon fiber itself has high strength and stiffness, while carbon fiber surface mats make use of the tightly arranged and interlaced structure of the fiber bundles, which makes the material have higher strength and stiffness.

2.Lightweight: Carbon fiber has lightweight characteristics, carbon fiber surface mats are lighter compared to metal materials, which can reduce the weight of the structure and improve the power density and energy efficiency of the product.

3. High-temperature resistance: Carbon fiber has good high-temperature resistance, which can maintain the strength and stability of the material in a high-temperature environment. Carbon fiber surface mats are often used in high-temperature processes and the preparation of materials in high-temperature environments.

4.Corrosion resistance: Carbon fiber has good resistance to acid, alkali and other corrosive substances, and can be used for a long time in harsh environments.

5. Good thermal insulation performance: Carbon fiber surface mat has good thermal insulation performance, which can effectively reduce heat conduction and block heat loss.

6.Plasticity and molding: Carbon fiber surface mat has good plasticity and molding performance, which can be cut, covered and molded according to the needs of processing, to adapt to a variety of applications that require complex shapes.

7. In short, carbon fiber surface mats have the advantages of high strength and stiffness, light weight, high temperature resistance, corrosion resistance, good thermal insulation, as well as plasticity and formability. This makes carbon fiber surface mats widely used in aerospace, automotive, energy, construction and other fields, playing an important role in enhancing product performance, reducing structural weight, improving durability and energy saving.

We are professional manufacture specialized in Fiberglass mesh,Fiberglass tape,corner tape, paper tape etc for more than 10 years.We have got the rich experience quality control and lead time, also we can supply you very competitive price.

Fiberglass alkali-resistant mesh cloth, made of medium alkali fiberglass woven fabric and alkali-free fiberglass woven fabric and applied with alkali-resistant coating, is an ideal engineering material in the construction industry.

Q1:What is your MOQ?

A1: Our MOQ is usually 1x20ft container.But we accept lower quantity for your trial order. Please feel free to inform us your plan for

purchasing, we will offer the price correspond to your qty. And we hope your would increase your order qty after you check our

product quality and know our services.

Q2: What is the shipping port?

A2: We ship the goods via Shanghai port.

Q3: How many colors are available?

A3:We can do custom color when reach our MOQ qty.

Our regular colors are white, yellow, green, blue, orange, red etc

Q4:What format of the file do you need if I want to do my own design?

A4: For printing label design, we need AI or PDF file for set up the print-plate.

Q5:,What is your delivery time?

A5:The time of delivery is about 20~30days after we receive the deposit.

Q6:What is your sample time?

A6:Usually we will take 7-10 days to make the samples.

Q7:Which Shipment way is available?

A7:By sea to your designated port.

Q8: Which Payment way is workable?

A8:1. Irrevocable L/C, Cash, PayPal, Credit card and T/T money transfers.

2.30% T/T deposit in advance, 70% balance before shipment after presentation of ready cargo.

3.L/C ( Irrevocable LC at sight)

If you need custom size such as gram weight and mesh size etc or private logo pls feel free inquiry us!

16 years + Manufacturer of Fiberglass mesh & Tapes Products, Don’t miss the opportunity to get the best quality products with the most competitive price.

Factory add:Fangxian Town, Danyang, Jiangsu, China, 212333

Whatsapp: 0086-13775339109

Email: fiberglassmesh@hotmail.com