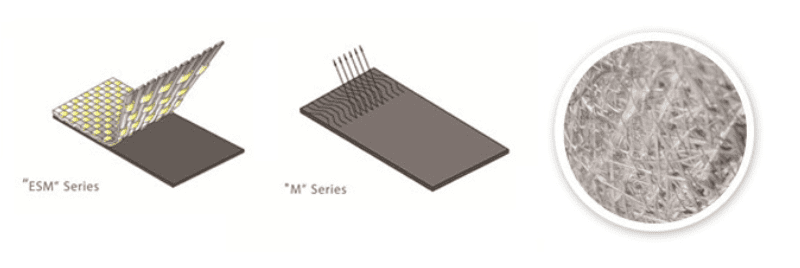

Glass fiber untwisted roving composite mat is a composite material consisting of untwisted roving and binder with the following advantages:

1. STRENGTH AND STIFFNESS: Fiberglass untwisted roving has high strength and stiffness, providing excellent structural support and reinforcement. The composite mats are held together by adhesives that hold the multiple layers of fiber cloth together, further adding to the strength of the material.

2. Heat Resistance: The glass fiber untwisted roving has excellent heat resistance and is able to withstand stress and heat transfer in high temperature environments. This makes the composite mat very suitable for high temperature working environments or applications where heat resistance is required.

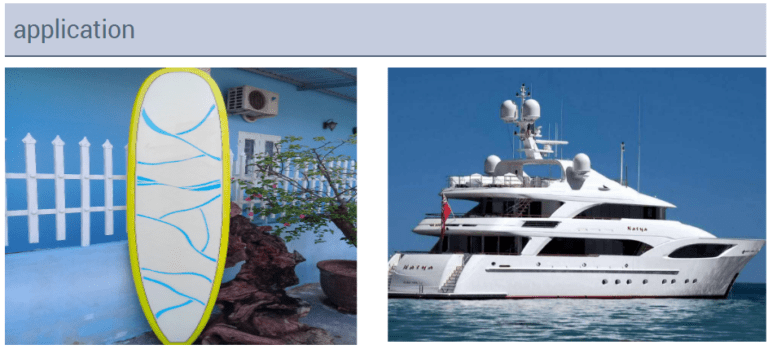

3.Corrosion resistance: Glass fiber untwisted roving has good resistance to chemical corrosion and can withstand acid, alkali and other chemicals, thus extending the service life of the material.

4.Lightweight: Compared with metal materials, glass fiber roving composite mats have a lower density, making the final product lighter in weight, which is conducive to improving the overall system efficiency and reducing energy consumption.

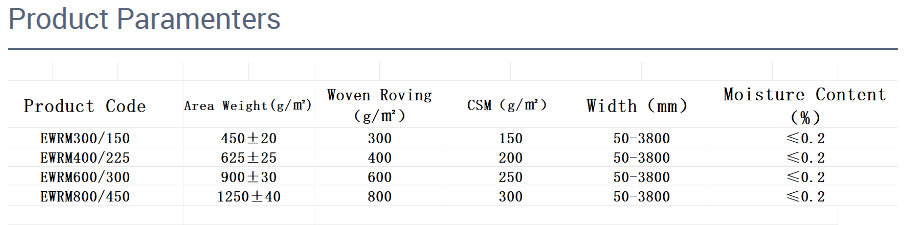

5. Adjustability: During the preparation process of glass fiber untwisted roving composite mats, parameters such as the number of fiber layers, density and binder distribution can be adjusted to meet the needs of different applications, enabling customized processing of the material.

6.Forming performance: glass fiber untwisted roving composite mat has good forming performance, can be made into various shapes of components through compression molding, thermoforming and other processing methods, suitable for complex shapes of product manufacturing.

7. Overall, glass fiber untwisted roving composite mats have the advantages of strength and stiffness, heat resistance, corrosion resistance, light weight, adjustability, and molding performance. These advantages have led to a wide range of applications in aerospace, automotive, construction, and electric power, especially for application scenarios that require high strength, heat and corrosion resistance.