- +86-13775339109

- Jessica@nq-fiberglass.cn

- No 61 Fangxian, Danyang, Jiangsu

If you’re looking for an effective way to prevent cracks in your plaster layer, fiberglass mesh could be the solution you need. Whether you’re using fiberglass mesh for stucco or opting for fiberglass mesh for waterproofing, this material provides excellent strength and flexibility, helping protect your plaster layer from cracks. In this article, we’ll dive into how fiberglass mesh helps enhance the durability of your plaster layer, ensuring your walls remain smooth and sturdy for a long time.

Fiberglass mesh is a reinforced mesh structure made from fiberglass materials, widely used in construction, renovation, and waterproofing. It provides exceptional tensile strength and durability by weaving fiberglass fibers into a net-like structure, effectively strengthening materials.The main component of fiberglass mesh is fiberglass yarn, which is specially treated to ensure it has waterproof, corrosion-resistant, and heat-resistant properties. It is commonly used to reinforce plaster layers, concrete walls, and other surfaces, helping to prevent cracking.

Fiberglass mesh comes in various types to suit different applications, including fiberglass netting mesh, fiberglass mesh sheets, and fiberglass mesh rolls. Each type has its unique characteristics:

No matter which type of fiberglass mesh you choose, it effectively strengthens surfaces, prevents cracks from spreading, and extends the lifespan of building materials.

| Class | Design | Density/25 mm | Weight (g/m2) | Tensile strength ≥ N/5 cm × 20 cm | Weaving type | Resin content (for self-adhesive) % | ||

|---|---|---|---|---|---|---|---|---|

| longitude | latitude | Wrap | Weft | |||||

| Standard | FM-DFT-01 | 8 | 6 | 55 | 550 | 450 | Leno | 28±2 |

| FM-DFT-02 | 9 | 9 | 60 | 550 | 500 | Leno | 28±2 | |

| FM-DFT-03 | 9 | 9 | 65 | 550 | 550 | Leno | 28±2 | |

| FM-DFT-04 | 9 | 9 | 70 | 550 | 600 | Leno | 28±2 | |

| FM-DFT-05 | 9 | 9 | 75 | 550 | 650 | Leno | 28±2 | |

| High strength | FM-DFT-06 | 20 | 10 | 75 | 700 | 700 | Plain | 28±2 |

| FM-DFT-07 | 5 | 5 | 100 | 1000 | 1000 | Leno | 28±2 | |

When you choose materials to prevent plaster layer cracking, fiberglass mesh offers numerous benefits that can enhance the quality of your construction and reduce maintenance costs. Here are the key advantages, designed with your needs in mind:

Overall, fiberglass mesh provides you with a cost-effective solution by offering high strength, durability, ease of installation, and low maintenance costs, helping you prevent plaster layer cracking while saving time, money, and ensuring long-term building stability.

From a practical construction perspective, fiberglass mesh plays a crucial role in preventing cracks in plaster layers. Its function is primarily based on the following aspects:

In construction, one of the main functions of fiberglass mesh is to enhance the structural stability of the plaster layer. Walls often face fluctuations in temperature and humidity, especially in regions with significant climate changes. The plaster layer expands and contracts with hot and cold cycles or changes in moisture content, making it prone to cracking without effective reinforcement. Fiberglass mesh helps to distribute the stresses caused by these temperature and moisture variations, preventing cracks caused by thermal expansion and contraction. In actual construction, fiberglass mesh is embedded within the plaster layer, forming a reinforced network that ensures the plaster remains strong and intact even during temperature and humidity changes.

During construction, fiberglass mesh not only serves as a reinforcement but also increases the flexibility and crack resistance of the plaster layer. Construction environments often involve vibrations, settlement, or external impacts, and relying solely on the strength of the plaster might not prevent cracks from forming. By using fiberglass mesh for stucco, it helps distribute these external forces evenly, preventing cracks and strengthening the overall wall. This is particularly important in high-risk areas where wall cracking is a concern, as fiberglass mesh provides essential support to maintain the integrity of the plaster layer.

In actual construction, waterproofing is a critical aspect. Especially for wet areas or exterior walls, fiberglass mesh for waterproofing becomes essential. It not only forms a waterproof barrier inside the plaster layer but also reduces the risk of water infiltration, preventing plaster from deteriorating due to moisture exposure. The waterproofing properties of fiberglass mesh ensure that the plaster layer remains stable even when exposed to moisture, which is vital for the long-term durability of the building.

-e1723010127838.webp)

During construction, workers typically apply a layer of fiberglass mesh either on the base or surface of the plaster layer. It’s essential to ensure that the mesh completely covers the surface and adheres tightly to the plaster for the best reinforcement effect. Special attention must be paid to ensure the mesh is smooth and free of air pockets to avoid local failure. In the long run, the strength and waterproofing properties of fiberglass mesh reduce the need for repairs, saving time and costs.

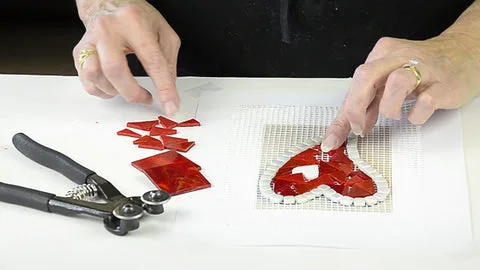

In construction, fiberglass mesh has become a key material due to its versatility and effectiveness. Whether it’s used for stucco reinforcement, exterior wall waterproofing, or for patchwork and joint reinforcement, fiberglass mesh provides significant benefits. Here are the main applications of fiberglass mesh in construction:

When you’re working with stucco for exterior or interior walls, using fiberglass mesh for stucco can greatly enhance the durability and crack resistance of the plaster layer. Since stucco is naturally brittle and prone to cracking due to environmental changes (such as temperature fluctuations and humidity), adding fiberglass mesh helps distribute stress and increases the strength of the plaster layer, ensuring stronger, longer-lasting walls. This means your stucco can better withstand external pressure and maintain its integrity over time, reducing the occurrence of cracks.

If you’re working in a damp environment or need to add a waterproof layer, fiberglass mesh for waterproofing is an excellent choice. It not only prevents moisture from penetrating the walls or floors but also enhances the stability of the waterproof layer. In practical applications, fiberglass mesh is often combined with waterproof coatings to form a robust protective barrier. This composite material can effectively resist water pressure and infiltration, ensuring that walls remain undamaged even after prolonged exposure to moisture. To achieve the best results, make sure the waterproof coating is applied evenly, and the mesh is fully embedded within it.

In construction, fiberglass tape is an essential tool for patchwork and joint reinforcement. Fiberglass tape is used primarily for reinforcing joints between plasterboards, patching cracks, and strengthening weakened areas. It helps improve adhesion at joints and prevents cracks from extending due to wall movement or temperature changes. Additionally, fiberglass tape is frequently used in waterproofing and anti-crack projects, offering robust reinforcement to repaired areas, ensuring they remain durable and stable.

When considering the use of fiberglass mesh, you may wonder: Does fiberglass decompose over time? The answer is: Not likely. Due to its exceptional durability and long lifespan, fiberglass mesh is widely used in the construction industry. Its stability and resistance to aging allow it to be used in harsh environments for an extended period. Here are some key points about the longevity of fiberglass mesh and its resistance to decomposition:

One of the notable features of fiberglass mesh is its remarkable durability. It can withstand temperature fluctuations, moisture, UV rays, and other environmental impacts without easily deteriorating. Unlike metal mesh, fiberglass mesh does not rust and is not affected by oxidation, making it highly durable for long-term use in both exterior and interior walls. You’ll find that even after extended use, fiberglass mesh for stucco or waterproofing projects remains intact with no significant performance decline.

While fiberglass mesh is highly durable, its long-term performance can still be influenced by certain environmental factors, especially extreme weather conditions or excessive exposure to UV rays. Does fiberglass decompose? In typical usage conditions, fiberglass mesh does not decompose easily. Its UV resistance allows it to remain stable in normal environments, but prolonged exposure to extreme heat, humidity, or intense sunlight could potentially affect its structure over time. To mitigate this, using a protective coating during installation can enhance its resistance to aging and prolong its lifespan.

To ensure the long-term stability of fiberglass mesh, you can take simple maintenance steps. For outdoor or sun-exposed areas, using UV protective coatings can significantly extend the lifespan of fiberglass mesh. In high-humidity or wet environments, pairing it with waterproof coatings for added protection is also a good idea. This not only helps prevent surface damage to the fiberglass mesh but also guards against performance degradation caused by environmental factors.

When considering the use of fiberglass mesh, you may wonder: Does fiberglass decompose over time? The answer is: Not likely. Due to its exceptional durability and long lifespan, fiberglass mesh is widely used in the construction industry. Its stability and resistance to aging allow it to be used in harsh environments for an extended period. Here are some key points about the longevity of fiberglass mesh and its resistance to decomposition:

If you’re looking for high-quality fiberglass mesh products, you can refer to the following links. These products are carefully selected to ensure outstanding durability and performance:

View High-Quality Fiberglass Mesh Products

Learn More About Choosing Fiberglass Mesh

By considering these factors, you’ll be able to select the best fiberglass mesh for your project, ensuring construction quality and long-term effectiveness. If you’re still unsure, feel free to contact our experts for further advice and assistance.

When reinforcing plaster with fiberglass mesh, proper installation is crucial to ensuring optimal results. Below is a step-by-step guide for installation, along with practical tips to ensure the best performance.

By following these steps, you can ensure that the fiberglass mesh performs at its best in your project. If you stick to these installation tips and perform the process correctly, you’ll end up with a more durable and crack-resistant plaster layer that improves the overall longevity of your walls.

Additional Tip: If you’re still looking for high-quality fiberglass mesh products, you can refer to the following links to choose the right mesh for your project.

16 years + Manufacturer of Fiberglass mesh & Tapes Products, Don’t miss the opportunity to get the best quality products with the most competitive price.

Factory add:Fangxian Town, Danyang, Jiangsu, China, 212333

Danyang NQ Sport And Fitness Co., Ltd

16 years + Manufacturer of Fiberglass mesh & Tapes Products, Don’t miss the opportunity to get the best quality products with the most competitive price.

Factory add:Fangxian Town, Danyang, Jiangsu, China, 212333