Products Categories

Featured Products

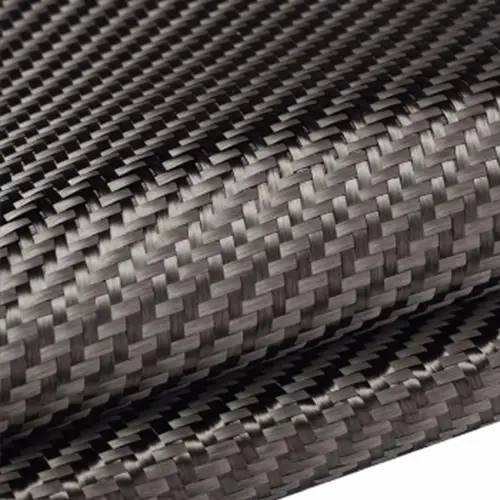

Ткань 2X2 Twill из углеродного волокна

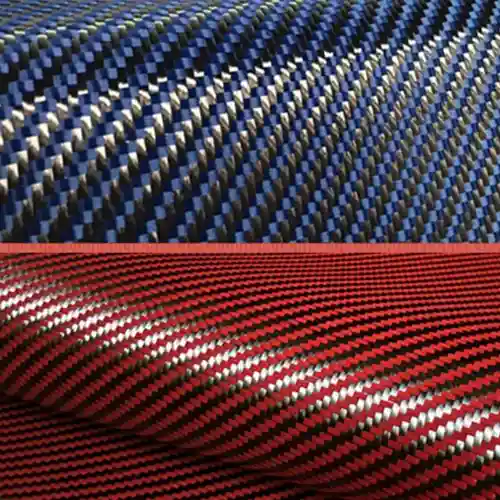

Настройка цвета

2×2 Twill Carbon Fiber Fabric typically features a classic black or dark gray finish with a distinctive woven pattern. For projects that require a unique look, this carbon fiber fabric can be customized with color through tinted resins, transparent color films, or hybrid weaving with colored fibers like red or gold Kevlar®. These color variations are ideal for automotive trim, consumer electronics, and custom design applications. Minimum order quantities may apply for colored carbon fiber fabric.

Customized services are available at any time. Please note your requirements in the form or contact us directly.

MOQ продукта

Пожалуйста, обратите внимание на наше минимальное количество заказа для Carbon Fiber Fabric. Для различных спецификаций ткани из углеродного волокна, MOQ отличается. Для индивидуальной ткани из углеродного волокна, из-за различных требований к настройке, MOQ должен быть подтвержден в соответствии с фактической ситуацией.

Настройка

Фабрики NQ могут изготавливать различные варианты ширины и длины в соответствии с потребностями проекта, чтобы обеспечить оптимальное использование материалов.

Гибкость заключается и в упаковке, которая может быть изготовлена в соответствии с требованиями заказчика, включая упаковочные материалы, этикетки, печать и т.д., чтобы удовлетворить потребности различных проектов.

Большой или маленький заказ

Заказывайте по одной или тысячам позиций одновременно. Наш склад и гибкая система доставки доступны для заказов в последнюю минуту и в сжатые сроки.

Danyang NQ Glass Fiber Weaving Co., Ltd. — A trusted Chinese Carbon fiber manufacturer with 16+ years of experience, 500+ skilled staff, and 2,560+ production machines delivering quality you can rely on.

- As NQ Factory, we specialize in the production of 2X2 Twill Carbon Fiber Fabric, a high-performance carbon fiber fabric that boasts exceptional strength, modulus, lightweight properties, and corrosion resistance. Its unique 2X2 weaving structure alternates fiber bundles in both warp and weft directions, creating a stable grid that offers superior physical performance and durability.

- In terms of customization, we leverage advanced production equipment and a professional technical team to flexibly adjust the fabric’s specifications, density, fiber type, as well as color and surface treatment based on specific customer needs. We are committed to providing personalized solutions that perfectly meet customer expectations and application requirements.

- In terms of production advantages, NQ Factory boasts efficient production capabilities, a strict quality control system, a diverse product range, and professional technical support. We strive to provide customers with high-quality 2X2 Twill Carbon Fiber Fabric, reliable delivery, and comprehensive services, helping them gain a competitive edge in the fierce market. Whether it’s in aerospace, automotive manufacturing, sports equipment, or other high-end applications, we can provide reliable carbon fiber fabric solutions.

Технические характеристики

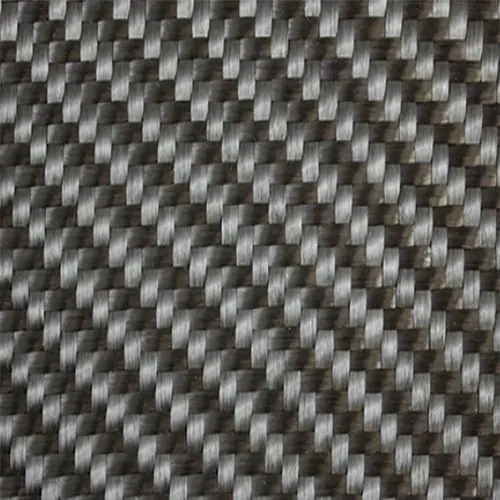

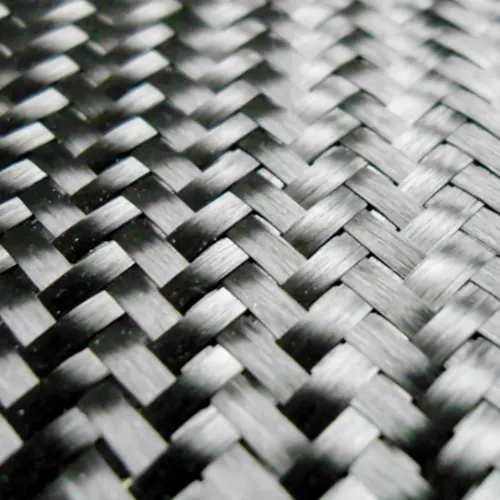

- Weave Pattern: 2×2 Twill Weave

- Each fiber passes over two and under two fibers, creating a diagonal pattern.

- Offers a visually appealing surface with better drapability than plain weave.

- Suitable for contouring over complex shapes.

- Areal Weight

- Typical range: 200g/m² to 400g/m²

- Common examples:

- 200g/m² (6 oz)

- 240g/m² (7.2 oz)

- 300g/m² (9 oz)

- Areal weight affects laminate thickness and mechanical properties.

- Fiber Type

- Usually made from PAN-based carbon fibers such as T300, T700, T800.

- High Strength (HS) or High Modulus (HM) fibers available upon request.

- Ширина

- Standard widths: 1000mm, 1270mm, 1500mm (customizable).

- Various widths available for hand lay-up or automated processes.

- Nominal Thickness

- Typically ranges from 0.2mm to 0.5mm, depending on areal weight and weave density.

- Can be layered to meet specific structural requirements.

- Yarn Density (Ends/Picks)

- Refers to the number of warp and weft yarns per unit length.

- Example: 5×5 per cm or 12×12 per inch.

- Impacts fabric tightness and mechanical uniformity.

- Resin Compatibility

- Compatible with a wide range of resins: epoxy, phenolic, polyester, etc.

- Surface treatment (e.g., sizing) available to enhance resin adhesion.

Main applications

Индустрия спортивного оборудования

- Tennis Rackets: High-end tennis rackets widely adopt carbon fiber bidirectional fabrics as composite materials. These fabrics utilize the lightweight and high-strength properties of carbon fiber to achieve weight reduction while maintaining strength, enhancing players’ swing speed and responsiveness.

- Golf Clubs: Carbon fiber bidirectional fabrics are used in golf clubs to enhance stability and durability while reducing weight, improving swing speed and accuracy.

- Snowboards: High-performance snowboards utilize carbon fiber bidirectional fabrics to increase stability and durability while maintaining lightweight characteristics, enhancing riders’ comfort and safety.

Автомобильная промышленность

- Car Bodies: Carbon fiber reinforced polymer matrix composites are one of the lightest materials for manufacturing automotive bodies. The adoption of such materials can reduce vehicle weight by approximately 40% to 60% while maintaining sufficient strength and stiffness. For example, the carbon fiber passenger cell of the BMW i3 reduces weight by 50%, and the General Motors ultra-lightweight concept car achieves a 68% weight reduction using a carbon fiber body and chassis.

- Car Wheels: The high strength, impact resistance, and durability of carbon fiber make it an ideal material for car wheels, capable of supporting the entire weight of the vehicle and cargo while improving driving safety.

Аэрокосмическая промышленность

- Aircraft Structures: Carbon fiber composite materials are widely used as the primary load-bearing structural materials for large advanced aircraft, such as missile weapons, space platforms, and carrier rockets. Their lightweight properties help reduce energy consumption and improve flight efficiency.

- Satellites and Space Stations: Carbon fiber composite materials are used to manufacture load-bearing cylinders, honeycomb panels, baseplates, and other structural components for satellites and space stations, ensuring small structural deformation, good load-bearing capacity, radiation resistance, aging resistance, and good tolerance to space environments.

Другие поля

- Wind Turbine Blades: Carbon fiber is extensively used in the manufacture of wind turbine blades due to its lightweight and high-strength properties, helping improve the efficiency and service life of wind turbine units.

- Special Tubes and Cylinders: Carbon fiber is employed in the manufacture of special tubes and cylinders to enhance their pressure resistance and corrosion resistance.

- Medical and Industrial Equipment: Carbon fiber is also used in medical and industrial equipment, such as the fabrication of artificial limbs and surgical instruments.

Характеристики

- Excellent Strength and Stiffness

- High tensile strength and modulus of elasticity.

- Provides strong load-bearing capacity in structural applications.

- Good Drapability and Conformability

- Twill weave offers more flexibility than plain weave.

- Conforms well to complex contours, reducing wrinkles and stress concentrations during layup.

- High Strength-to-Weight Ratio

- Low density (~1.6 g/cm³) with outstanding mechanical properties.

- Ideal for lightweight yet strong composite structures.

- Attractive Surface Finish

- Distinctive 2×2 twill pattern delivers a clean and uniform visual texture.

- Frequently used in exposed carbon fiber parts for aesthetic appeal.

- Excellent Fatigue Resistance

- Maintains mechanical performance under repeated loading.

- Suitable for dynamic or cyclic load environments.

- Corrosion and Chemical Resistance

- Highly resistant to most acids, alkalis, and solvents.

- Maintains integrity in harsh chemical or outdoor conditions.

- Good Thermal Stability

- Carbon fiber can withstand high temperatures (resin-dependent).

- Minimal degradation under thermal stress or cycling.

| Артикул | Технические характеристики |

|---|---|

| Weave Pattern | 2×2 Twill Weave |

| Номер модели | NQ-3K-TW200 (example, customizable) |

| Fiber Type | T300 3K Carbon Fiber (T700, T800 optional) |

| Areal Weight | 200 g/m² ±5% |

| Yarn Specification | 3K (3000 filaments per tow) |

| Ширина | 1000mm / 1270mm / 1500mm (customizable) |

| Толщина | 0.28 mm ±0.03 mm |

| Weaving Method | 2×2 Twill |

| Sizing Type | Epoxy Compatible |

| Roll Length | 100 meters/roll (customizable) |

| Артикул | Typical Value |

|---|---|

| Прочность на разрыв | 3530 MPa |

| Tensile Modulus | 230 GPa |

| Elongation at Break | 1.5% |

For more product specifications, please contact our professionals!

- ISO & CE Certified Manufacturing

- Certified to ensure consistent quality and international compliance.

- Custom Weave Patterns & Colors

- Advanced 3D looms support plain, twill, satin, honeycomb, aramid blends, and colors like black, blue, and red.

- Bulk Supply in Multiple Specs

- Available in 120g/m², 200g/m², 320g/m², 400g/m²; options include 1K, 3K, 6K, 12K with customizable thickness, density, and length.

- Competitive Pricing

- 26 production lines ensure fast delivery and cost-effective, high-quality output for your market edge.

Enhance Performance, Simplify Processing, Reduce Costs

Choose Carbon Fiber Fabric for exceptional strength and stability that elevates your product quality. Streamline your manufacturing, cut production time, and gain a competitive edge today!