Products Categories

Featured Products

Шестигранная трубка из углеродного волокна

The hexagonal carbon fiber tube is a high-performance composite with a hexagonal cross-section, made from premium carbon fiber and resin matrix. It offers exceptional strength-to-weight ratio, rigidity, and dimensional stability, making it ideal for precision engineering and structural applications.

MOQ продукта

Пожалуйста, обратите внимание на минимальное количество заказа трубок из углеродного волокна. Для обычных трубок из углеродного волокна на складе, нет MOQ. Для индивидуальной трубки из углеродного волокна, MOQ должен быть подтвержден в соответствии с фактической ситуацией, потому что индивидуальные требования отличаются.

Настройка

NQ поможет вам на протяжении всего проекта: цвет, способ плетения, ширина, длина и т.д. Свяжитесь с нами или укажите свой запрос в форме.

Большой или маленький заказ

Заказывайте по одной или тысячам позиций одновременно. Наш склад и гибкая система доставки доступны для заказов в последнюю минуту и в сжатые сроки.

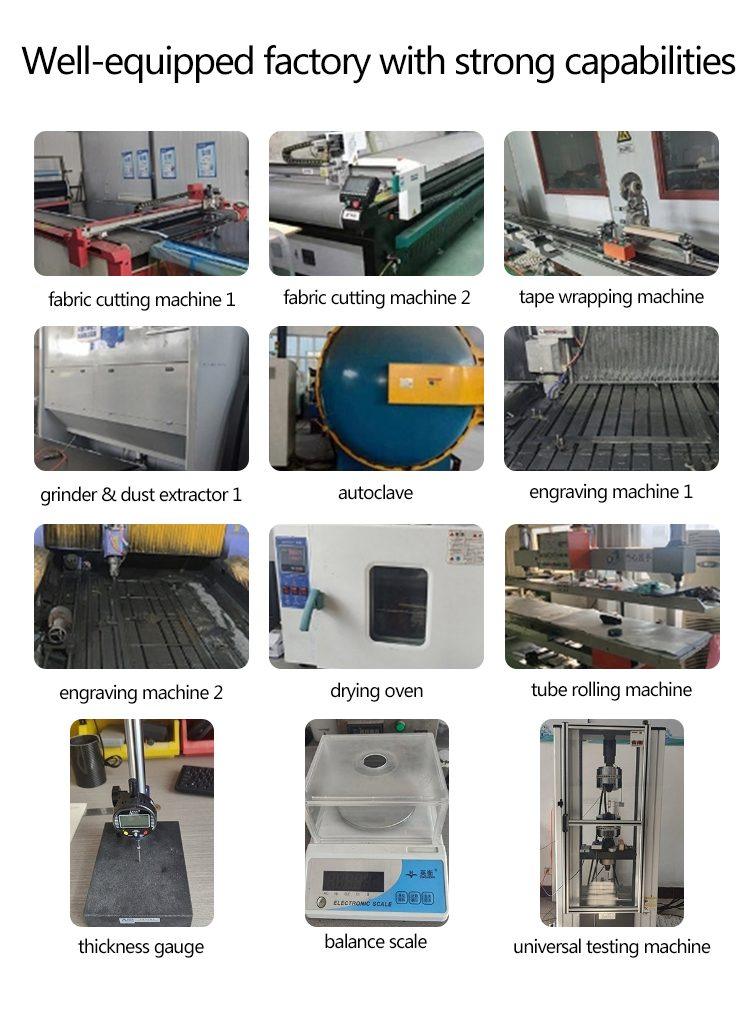

Danyang NQ Glass Fiber Weaving Co., Ltd. — A trusted Chinese Carbon fiber manufacturer with 16+ years of experience, 500+ skilled staff, and 2,560+ production machines delivering quality you can rely on.

- Hexagonal Carbon Fiber Tube, a tubular structure with a hexagonal cross-section made of carbon fiber material, is renowned for its superior physical properties such as high modulus, low density, heat resistance, and corrosion resistance. These characteristics have led to its widespread application in various fields.

- When customizing Hexagonal Carbon Fiber Tubes in a factory, precise control over dimensions like inner diameter, outer diameter, and length is crucial to ensure alignment with customers’ design drawings. Additionally, the factory must select the appropriate carbon fiber material and molding process based on the customer’s needs and intended application to guarantee the tube’s required strength and durability.

- The factory’s customization capabilities are reflected in its ability to accurately interpret drawings, precisely select materials, and optimize molding processes. The integrated application of these capabilities ensures that Hexagonal Carbon Fiber Tubes meet customers’ specific needs while maintaining stable and reliable performance and quality.

Технические характеристики

- Side Length:

Common range: 5 mm – 50 mm (customizable on request) - Flat-to-Flat Width:

Approximately 1.732 × side length, used for overall dimension reference - Wall Thickness:

Standard options: 0.5 mm, 1.0 mm, 1.5 mm, 2.0 mm

(multi-layer construction available for enhanced strength) - Длина:

Standard lengths: 1000 mm / 2000 mm

Custom lengths up to 3000 mm+ available - Material Composition:

- Carbon fiber types: T300, T700, T800, 3K twill weave, UD (unidirectional)

- Resin system: Epoxy resin (excellent thermal and chemical resistance)

- Surface Finish:

- Glossy

- Matte

- 3K twill or plain weave texture

- Manufacturing Process:

- Roll-wrapping (most common)

- Compression molding

- Pultrusion (less common for hexagonal profiles)

Main applications

Аэрокосмическая промышленность

- Hexagonal Carbon Fiber Tube plays a crucial role in the aerospace industry. Its lightweight yet high-strength properties, along with its resistance to high temperatures and corrosion, make it an ideal material for manufacturing aircraft structural components, missile shells, and other critical parts. For example, the F22 fourth-generation fighter jet in the United States utilizes approximately 24% carbon fiber composite materials, significantly enhancing the aircraft’s performance.

- The use of carbon fiber composites significantly reduces the overall weight of aircraft, thus improving flight performance, such as increasing range and maneuverability.

Автомобильная промышленность

- In the automotive industry, Hexagonal Carbon Fiber Tube is primarily used in components such as car bodies, chassis, and seats. Lightweighting these parts can improve fuel efficiency, reduce emissions, and enhance the vehicle’s impact resistance and corrosion resistance.

- Carbon fiber composite materials make cars more environmentally friendly, energy-efficient, and improve driving comfort and safety.

Индустрия спортивного оборудования

- Hexagonal Carbon Fiber Tube finds extensive application in sports equipment, including golf clubs, bicycle frames, and fishing rods. Carbon fiber’s lightweight yet high-strength properties enable these equipment to be lighter, more durable, and improve athletes’ competitive performance.

- For instance, carbon fiber bicycle frames are lighter than traditional metal frames but stronger, making cycling easier and enhancing speed and control.

Wind Power Industry

- As wind turbine generators increase in power, the size of their blades also grows. To reduce blade weight and improve its strength and stiffness, Hexagonal Carbon Fiber Tube is extensively used in the manufacturing of wind turbine blades.

- Carbon fiber composite materials make blades lighter, stronger, and improve the wind turbine generator’s efficiency and reliability.

Industrial and Civil Construction

- Hexagonal Carbon Fiber Tube is used in reinforcement and strengthening in industrial and civil construction, particularly for buildings, railways, bridges, and tunnels.

- Carbon fiber composite materials, with their low density, high strength, durability, and corrosion resistance, are ideal for strengthening and reinforcing structures. Roofing trusses made from carbon fiber tubes are approximately 50% lighter than steel, significantly improving construction efficiency and seismic performance.

Характеристики

- High Strength-to-Weight Ratio

Delivers exceptional mechanical strength while remaining extremely lightweight, ideal for weight-sensitive structures. - Superior Rigidity

The hexagonal geometry enhances torsional and bending stiffness compared to round tubes of similar dimensions. - Устойчивость размеров

Low thermal expansion and high structural integrity ensure consistent performance under varying temperatures and loads. - Improved Fit and Alignment

The flat sides of the hexagonal profile allow for easier alignment, interlocking, or anti-rotation assembly in structural systems. - Corrosion and Chemical Resistance

Made from high-grade carbon fiber and epoxy resin, the tubes offer strong resistance to moisture, chemicals, and UV degradation. - Aesthetic and Functional Surface Finish

Available in glossy or matte finishes with visible weave patterns, offering both a premium appearance and functional surface grip. - Customizability

Easily tailored in terms of size, wall thickness, fiber orientation, and finish to meet specific structural or design requirements.

For more product specifications, please contact our professionals!

By adopting CNC precision processing technology and automatic detection systems and integrating automated winding, curing, and cutting processes, the production speed is increased by 20% to 30%. Multi-station collaborative operation reduces manual intervention and reduces the error rate.

- Compatible with carbon fiber prepregs such as T300, T700, T800

- Supports a variety of resin systems such as epoxy and phenolic

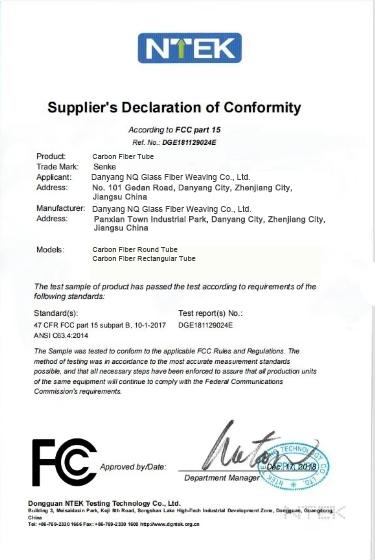

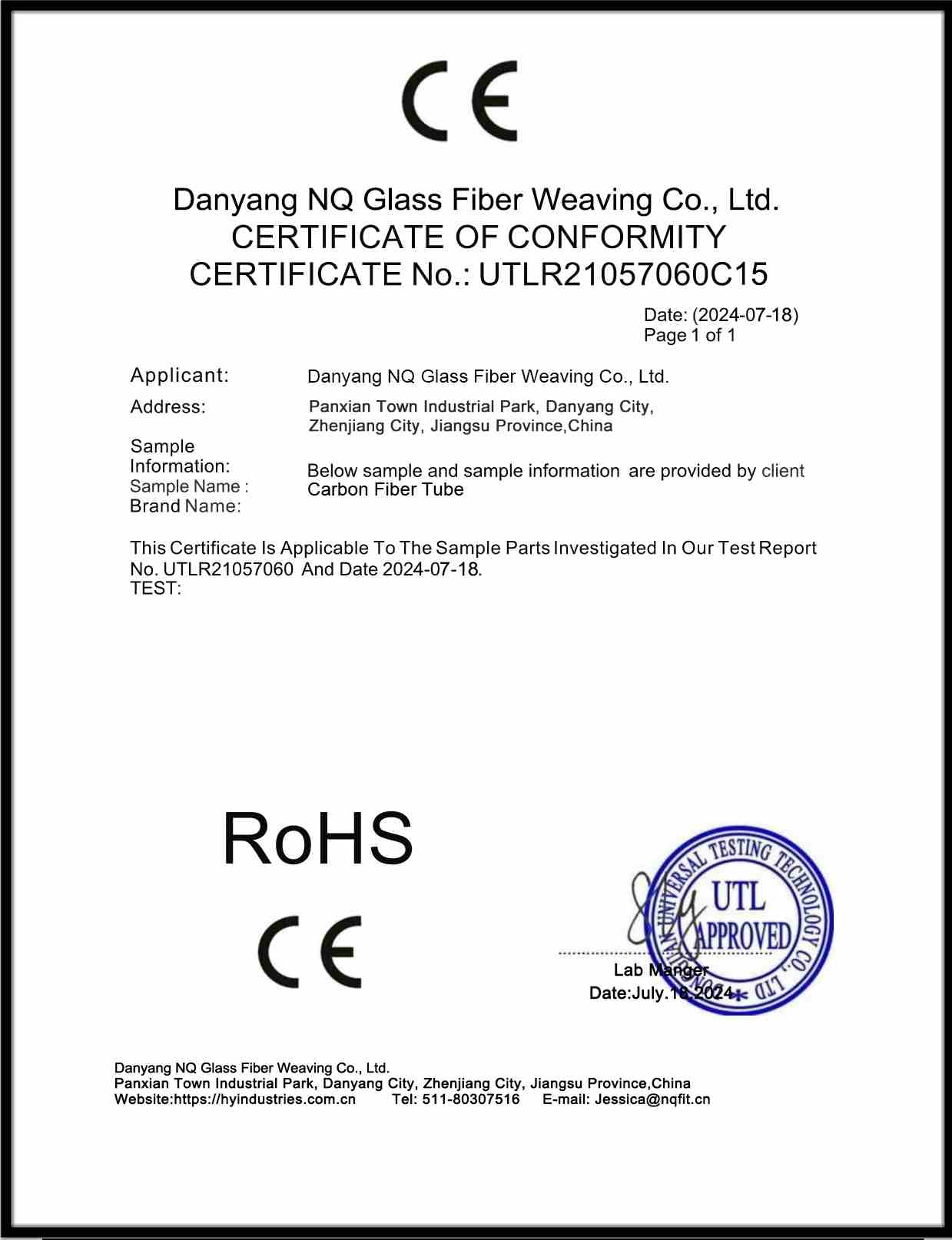

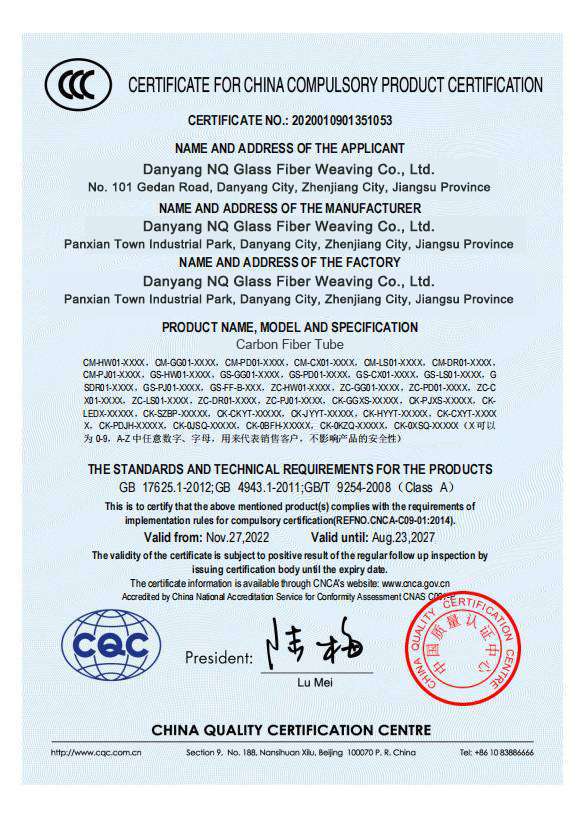

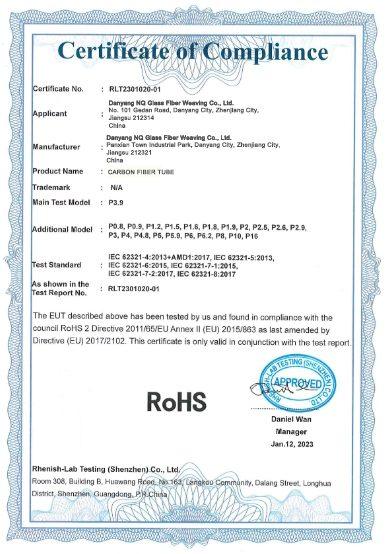

- ISO 9001, CE, SGS, and ASTM standards

- 40 automated production lines to ensure on-time delivery

- In-house Strictly Testing Lab for 6-step internal inspection

Enhance Performance, Simplify Processing, Reduce Costs

Experience the power of Carbon Fiber Tubes—lightweight, ultra-strong, and corrosion-resistant. Perfect for industries demanding high performance and durability. Elevate your products with precision-engineered tubes that combine advanced materials with cutting-edge manufacturing. Choose carbon fiber tubes for unmatched strength, reduced weight, and superior reliability.