- +86-13775339109

- Jessica@nq-fiberglass.cn

- No 61 Fangxian, Даньян, Цзянсу

Glassfiber surface mat is made of wet forming process, the product has the characteristics of flat surface and corrosion resistance. According to the product use can be divided into surface felt, roof felt, floor felt, insulation felt and so on. The products are mainly used in winding pipes, insulation and sound insulation, new building materials, new energy vehicles, environmental protection and other fields.

Product features:

1. Flat surface: It has a flat and smooth surface, which can provide a good appearance.

2. Uniform distribution: The fibers are evenly distributed throughout the structure, providing balanced strength and stiffness.

3.Good penetration: It has good resin penetration, which is conducive to the penetration and curing of the resin.

4. Enhance adhesion: It can enhance the adhesion between the resin and improve the durability and stability of the material.

5. Wear resistance: It has good wear resistance and extends the service life of the product.

6. Corrosion resistance: It has certain resistance to chemical corrosion and is suitable for use in various harsh environments.

7. Easy to operate: the surface felt has good clementability and plasticity, easy to operate and apply.

Surface Finish Improvement: One of the primary functions of glass fiber surface mat is to enhance the surface finish of composite products. It provides a smooth and uniform surface that is suitable for painting, laminating, or coating.

Print-Through Prevention: Glass fiber surface mat helps prevent print-through of underlying reinforcement materials, such as woven roving or chopped strand mat, by providing a barrier between the resin and the reinforcement layer.

Resin Flow Control: The open structure of the surface mat allows for controlled resin flow during the lamination process, ensuring proper wet-out of the fibers and reducing excess resin accumulation on the surface.

Improved Surface Strength: By adding a layer of glass fiber surface mat, the overall surface strength of the composite part is enhanced, providing better impact resistance and durability.

Corrosion Resistance: Glass fiber surface mat can improve the corrosion resistance of composite products, making them suitable for applications in harsh environments or where exposure to chemicals is a concern.

Easy to Handle and Apply: The lightweight and flexible nature of glass fiber surface mat make it easy to handle and apply to complex shapes and contours, facilitating the manufacturing process.

Compatibility with Various Resins: Glass fiber surface mat is compatible with polyester, vinyl ester, and epoxy resins, allowing for versatility in composite manufacturing processes.

Weatherability: Glass fiber surface mat provides UV resistance and weatherability, making it suitable for outdoor applications where exposure to sunlight and environmental elements is a consideration.

Marine Industry: In the marine industry, NQ Glass Fiber Surface Mat is used in boat building and repair to enhance the surface finish of hulls, decks, and other components. It helps provide a smooth and uniform surface that is resistant to water and improves the overall aesthetics of the vessel.

Автомобильная промышленность: NQ Glass Fiber Surface Mat is utilized in the automotive sector for manufacturing components with high-quality surface finishes, such as car body panels, spoilers, and interior parts. It helps prevent print-through and enhances the appearance of the final product.

Construction Sector: In the construction industry, NQ Glass Fiber Surface Mat is applied in the production of composite building materials like panels, facades, and architectural elements. It improves the surface strength and weather resistance of these structures, making them durable and aesthetically pleasing.

Wind Energy: NQ Glass Fiber Surface Mat plays a role in the wind energy sector for manufacturing wind turbine blades. By providing a smooth and uniform surface, it helps optimize aerodynamic performance and contributes to the longevity of the blades in challenging environmental conditions.

Recreational Vehicles: The RV industry utilizes NQ Glass Fiber Surface Mat in the production of recreational vehicles, camper trailers, and motorhomes. It enhances the surface finish of exterior components, improving durability and visual appeal.

Water Tanks and Pipes: NQ Glass Fiber Surface Mat is used in the fabrication of water tanks, pipes, and other fluid transportation systems. It helps reinforce the structures and provides corrosion resistance for long-term performance.

General Composite Manufacturing: NQ Glass Fiber Surface Mat is widely used in general composite manufacturing processes where surface finish enhancement and print-through prevention are required. It is applied in various applications ranging from aerospace to sporting goods.

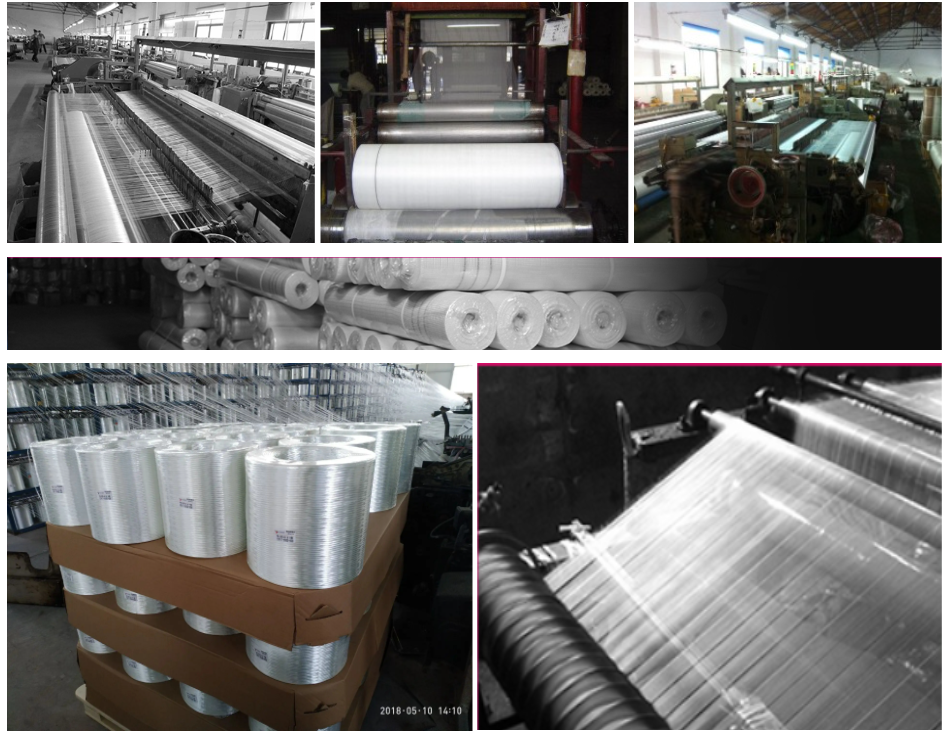

The raw materials for preparing silicate glass usually include silica, alumina, calcium oxide, etc. These materials are proportioned and then fed into a furnace for melting.

Molten glass through high-speed rotating centrifuge or jet method, the glass liquid is drawn into a fiber, and then cooled and solidified to form glass fiber cotton or glass fiber wire.

Glass fibers are coated to enhance their durability and adhesion, and wetted to improve their compatibility with materials such as resins.

The coated glass fiber is dried to remove water and make it meet the moisture content standard required by the product.

Glass fiber is cut and twisted as needed to synthesize glass fiber products of various sizes and lengths.

The fiberglass product is finally packaged, stored and transported for use in the manufacturing process.

Наш MOQ обычно составляет 1x20ft контейнер. Но мы принимаем меньшее количество для вашего пробного заказа. Пожалуйста, не стесняйтесь сообщить нам ваш план для

покупая, мы предложим цену, соответствующую вашему количеству. И мы надеемся, что вы увеличите количество заказов после того, как вы проверите наши

качество продукции и узнать о наших услугах.

Мы отправляем товары через порт Шанхая.

Мы можем сделать пользовательский цвет, когда достичь нашего MOQ qty.

Наши обычные цвета: белый, желтый, зеленый, синий, оранжевый, красный и т.д.

Для печати дизайна этикетки нам нужен файл AI или PDF для создания печатного шаблона.

Время доставки составляет около 20 ~ 30 дней после получения депозита.

Обычно на изготовление образцов уходит 7-10 дней.

По морю до назначенного порта.

1. Безотзывный аккредитив, наличные, PayPal, кредитная карта и денежные переводы T/T.

2.30% T/T депозит заранее, 70% баланс перед отгрузкой после представления готового груза.

3.L/C (безотзывный аккредитив по предъявлении)

Если вам нужен пользовательский размер, такой как вес грамма и размер ячейки и т.д. или частный логотип, пожалуйста, не стесняйтесь запрашивать нас!

© All Rights Reserved.