Products Categories

Featured Products

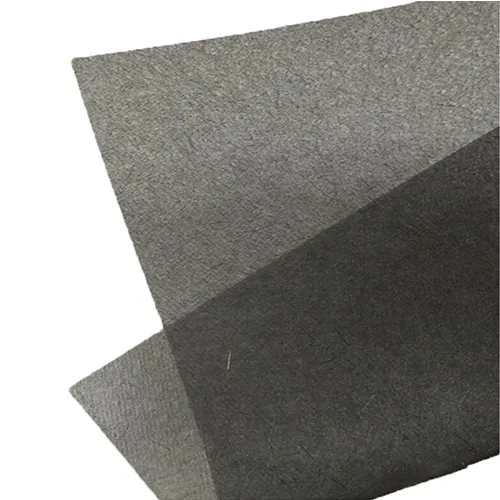

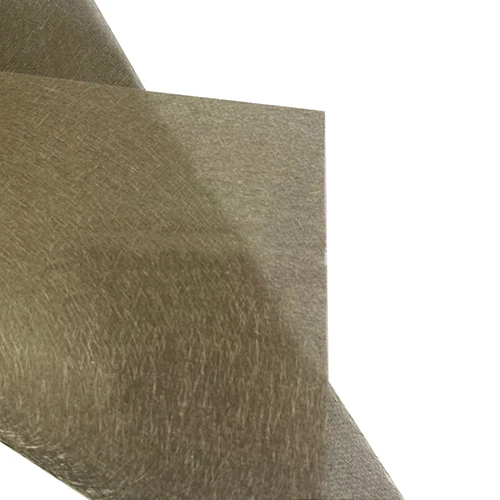

Поверхностный коврик из углеродного волокна

A коврик из углеродного волокна is a high-performance material available in various models, including options with 450 GSM and 600 GSM weights. These mats are lightweight, strong, and durable, providing a smooth, uniform surface ideal for composite products. With high strength-to-weight ratio and corrosion resistance, they are perfect for industries like automotive, aerospace, и marine.

MOQ продукта

Пожалуйста, обратите внимание на наш минимальный заказ для углеродного волокна мат. Для различных спецификаций коврика из углеродного волокна, MOQ отличается. Для индивидуального коврика из углеродного волокна, из-за различных требований к настройке, MOQ должен быть подтвержден в соответствии с фактической ситуацией.

Настройка

Фабрики NQ могут изготавливать различные варианты ширины и длины в соответствии с потребностями проекта, чтобы обеспечить оптимальное использование материалов.

Гибкость заключается и в упаковке, которая может быть изготовлена в соответствии с требованиями заказчика, включая упаковочные материалы, этикетки, печать и т.д., чтобы удовлетворить потребности различных проектов.

Большой или маленький заказ

Заказывайте по одной или тысячам позиций одновременно. Наш склад и гибкая система доставки доступны для заказов в последнюю минуту и в сжатые сроки.

Danyang NQ Glass Fiber Weaving Co., Ltd. — A trusted Chinese Carbon fiber manufacturer with 16+ years of experience, 500+ skilled staff, and 2,560+ production machines delivering quality you can rely on.

Технические характеристики

- 1. Model

- 450 GSM

- 600 GSM

- 800 GSM

- 1000 GSM

Customizable to meet specific performance needs.

- 2. Size

- Common Sizes:

- 1m x 1m

- 1.5m x 1.5m

- 2m x 2m

Custom sizes available upon request.

- 3. Fiber Type

- 100% Углеродное волокно

- Carbon Fiber & Glass Fiber Composite

Choose based on required strength, weight, and cost considerations.

- 4. Weaving Pattern

- Плетение гладкое: Uniform surface texture, ideal for standard applications.

- Плетение саржевое: Higher fabric density for enhanced tensile and compressive strength.

- Custom Weaves: Tailored to project-specific requirements.

- 5. Thickness

- Available Thicknesses:

- 0.2mm

- 0.5mm

- 1.0mm

Thickness adjusted according to GSM for specific structural needs.

- 6. Edge Finish

- Cutting: Precision cutting for accurate dimensions.

- Heat Sealing: Prevents fraying, enhancing durability and appearance.

- Unfinished Edges: Available for specific applications.

- 7. Weight

- 450 GSM

- 600 GSM

- 800 GSM

- 1000 GSM

Weight categorized by grams per square meter (GSM) for strength-to-weight balance.

- 8. Roll Width

- Standard Widths:

- 1m

- 1.5m

- 2m

Custom widths available for specific production requirements.

- 9. Temperature Resistance

- High-temperature versions available for applications requiring greater heat resistance.

- 10. Roll Length

- Standard Lengths:

- 50m

- 100m

Custom lengths available upon request.

Main applications

- 1. Automotive Industry

- Carbon fiber surface mats are widely used in the automotive sector to create lightweight car parts such as body panels, interior trim, и structural components. These mats help improve fuel efficiency and enhance performance, making them ideal for sports cars, electric vehicles, и high-performance automotive components.

- 2. Aerospace Industry

- In aerospace, carbon fiber mats are essential for manufacturing lightweight aircraft parts like aircraft wings, fuselages, и tail sections. They provide прочность and durability, making them perfect for reducing weight while improving fuel efficiency and performance.

- 3. Marine Industry

- The marine industry relies on carbon fiber mats for creating durable, corrosion-resistant boat parts, including hulls, decks, и propellers. These mats provide прочность and lightweight properties, extending the lifespan of boats and vessels in both recreational and commercial settings.

- 4. Sports Equipment

- Carbon fiber is a popular choice for sports equipment due to its combination of прочность and lightweight properties. It’s used in bicycles, tennis rackets, skis, и snowboards, helping athletes improve performance while reducing fatigue.

- 5. Construction & Infrastructure

- In construction, carbon fiber mats are used to reinforce structures like concrete facades, bridge decks, и high-rise buildings. They provide extra strength and stability, allowing for more durable structures that can endure harsh environments and weather conditions.

- 6. Renewable Energy

- For renewable energy applications, carbon fiber mats are key in manufacturing wind turbine blades and solar panel frames. They provide the required lightweight strength to withstand wind forces and resist environmental damage, making them ideal for renewable energy systems.

- 7. Industrial Applications

- Carbon fiber mats are used to produce high-strength industrial parts such as pressure vessels, machinery components, и pipes. Their chemical resistance and ability to withstand extreme temperatures make them ideal for demanding industrial environments.

- 8. Military and Defense

- In the military and defense sectors, carbon fiber mats are used for lightweight armor, ballistic protection gear, и defense systems. Their stealth properties make them crucial in creating stealth vehicles and aerospace defense technologies.

Характеристики

- 1. Lightweight Yet Strong

Carbon fiber surface mats are both lightweight and incredibly strong, offering a unique combination of performance and durability. This makes them ideal for applications in automotive, aerospace, и sports equipment, where high strength is needed without adding unnecessary weight. - Buyer Benefit: This performance helps reduce overall weight in vehicles and equipment, improving fuel efficiency, handling, и acceleration, while also boosting product performance.

- 2. High Durability and Longevity

Known for their high durability, carbon fiber mats can withstand extreme conditions, such as high temperatures, moisture, и chemical exposure. They are perfect for harsh environments, including aerospace and marine applications, where components need to endure wear and tear. - Buyer Benefit: With their long lifespan, carbon fiber mats minimize the need for frequent replacements, saving buyers on maintenance and repair costs.

- 3. High Strength-to-Weight Ratio

Carbon fiber surface mats have an excellent strength-to-weight ratio, which means they deliver outstanding strength while keeping the weight low. This makes them particularly useful in the automotive and aerospace industries, where reducing weight is crucial to enhance performance and fuel efficiency. - Buyer Benefit: The lighter weight improves fuel economy, handling, and overall efficiency, delivering a significant performance boost to vehicles and machinery.

- 4. Excellent Flexibility

Despite their robust strength, carbon fiber mats also exhibit excellent flexibility, making them suitable for applications that require molding into complex shapes. This quality is beneficial for customized parts in sports equipment, aerospace, и industrial manufacturing. - Buyer Benefit: Buyers can create customized, high-performance parts without compromising on strength or durability, offering more versatility in product design.

- 5. Resistance to Corrosion and Chemicals

Carbon fiber mats offer resistance to corrosion and many harsh chemicals, making them ideal for use in marine, chemical processing, и industrial settings. Their ability to withstand these challenging conditions ensures they maintain integrity and performance over time. - Buyer Benefit: The mats’ resistance to corrosion means reduced maintenance needs and a longer lifespan, which lowers the overall lifecycle costs of products.

- 6. Enhanced Surface Finish

Carbon fiber surface mats provide a smooth, polished finish, enhancing the aesthetic appeal of products like luxury vehicles, sports equipment, и consumer electronics. This high-quality finish gives products a sleek, modern look. - Buyer Benefit: Buyers can offer premium, visually appealing products that stand out in competitive markets, increasing product attractiveness and market demand.

- 7. Environmental Benefits

Carbon fiber mats contribute to sustainability by reducing energy consumption in industries like automotive and aerospace. Their lightweight properties help improve the energy efficiency of vehicles and machinery, which can lead to lower carbon emissions. - Buyer Benefit: Carbon fiber mats help businesses meet their green goals, supporting eco-conscious solutions that not only boost performance but also align with sustainability initiatives.

Продукт | Углеродный волокнистый мат/пластик/ткань/полотно |

Материал | Углеродное волокно |

Вес | 10g, 20g, 30g, 50g, 60g или подгонянный |

Ширина | 125 см или на заказ |

Длина | 300 м/рулон |

Содержание влаги | ≤0,5% |

Поверхностное удельное сопротивление | <10Ω |

Диаметр волокна | 6-7 мм |

Содержание связующего вещества | 3%-20% |

For more product specifications, please contact our professionals!

- Advanced Carbon Fiber Air Laid Machine

NQ’s machine uses high-quality fibers for high efficiency, precise control, energy saving, and wide application. - Powerful Production Capacity

Equipped with 3 punching needle lines and 6 weaving lines, using advanced tech and quality materials for efficient, standardized carbon fiber mat production. - Строгий контроль качества

NQ enforces rigorous QC from raw materials to delivery. All mats meet CE, ASTM, SGS, and BSC standards for top industry stability and consistency.

Maximize Strength, Improve Impact Resistance, Simplify Fabrication

Discover the power of Carbon Fiber Chopped Strand Mat — engineered to provide exceptional tensile strength and isotropic reinforcement thanks to its randomly oriented fibers. Its lightweight and flexible structure enhances impact resistance while enabling easy molding of complex shapes. Designed for seamless integration with multiple resin systems, it streamlines production and reduces waste. Choose Carbon Fiber Chopped Strand Mat to deliver durable, high-performance composites with consistent quality and cost efficiency.