Производство стекловолоконных матов Поставщик в Китае

- Опыт работы на производстве 16+

- Сертификация ISO, CE, BSCI, RoHS, SGS

- Профессиональные услуги oem и odm, универсальное решение.

- Цвет на заказ: белый, серый, черный и т.д.

- Настройка размеров: ширина 50-3800 мм, толщина 0,10-0,70 мм и т.д.

лет

Опыт работы на производстве

Проекты

Мы закончили

Клиенты

Над миром

Удовлетворенность

Производитель стекловолоконных матов

High-performance Automated Roller Press Machine

Our roller press machine provides uniform density compaction, and the rolling process also improves the surface quality of the fiberglass mat, making it smoother and more consistent, ensuring material strength and stability. It is also capable of handling a variety of different materials.

- Сертификаты ISO 9001, ISO 14001, CE, SGS, ASTM, OHSAS, ГОСТ и другие стандарты.

- 35 automated production lines.

- Good plasticity and fast resin penetration.

- High-quality raw materials: E glass, S glass, C glass and AR glass, etc.

- Строгие испытания: прочность на разрыв, устойчивость к высоким температурам, коррозионная стойкость и т.д.

Профессия

Передовые технологии производства

Высокое качество

Высокое качество CE, ASTM, SGS, ISO, BSCI сертификации

Эффективная стоимость

Прямая заводская цена

На заказ

Различные размеры, цвета, конструкции, OEM/ODM

Сервис

Отличное обслуживание клиентов

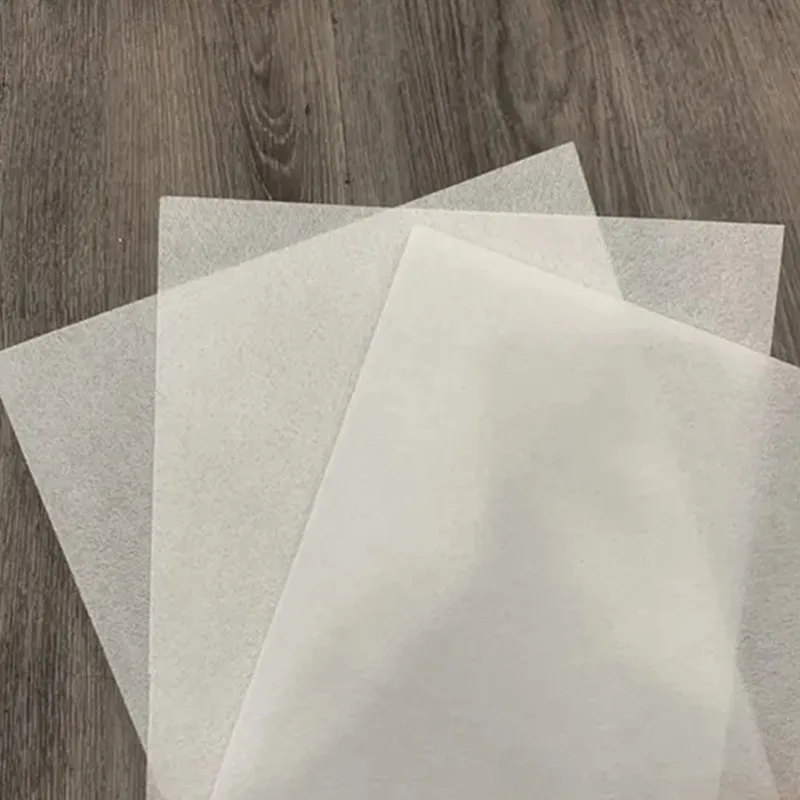

Fiberglass Mat Hot Sale Series

Our fiberglass mats are available in bulk quantities with weights between 10 g/m² and 1300 g/m², with additional custom weights and widths available to suit your packaging needs. Worried about shipping? Rest assured that our wholesale fiberglass mats are wrapped in waterproof plastic and packaged in crash-resistant cartons or wooden boxes. Whether retail or wholesale, our custom options ensure your brand stands out. Enhance your product line with our premium fiberglass mats and leave a lasting impression on your customers.

Различные типы стекловолоконных матов

NQ Fiberglass has produced a wide range of fiberglass felt for over 16 years, including continuous fiber felt, chopped fiber felt, fiberglass surface tissue paper, fiberglass needle felt, and fiberglass composite felt. We also offer customization based on your specifications, such as weight, length, width, coating, and packaging. This allows you to avoid the hassle of contacting multiple suppliers to meet your needs.

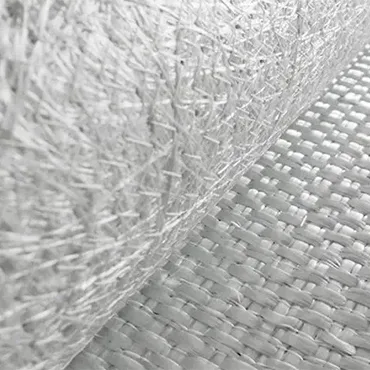

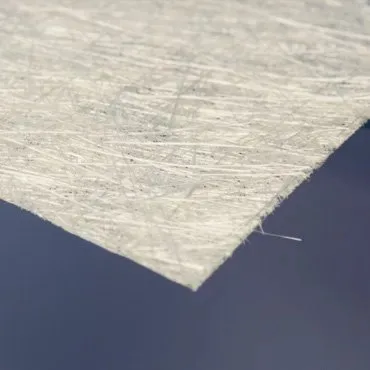

Маты из непрерывной нити

Continuous filament felt is made from filament yarn and features a nonwoven structure containing an insoluble adhesive. It can be used in both non-filled and filled resin systems and is compatible with unsaturated polyester, epoxy, and polyamine resins.

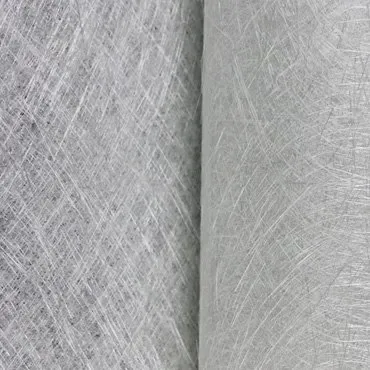

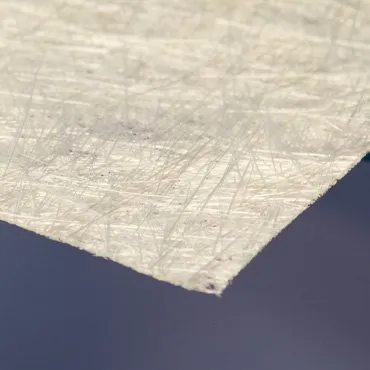

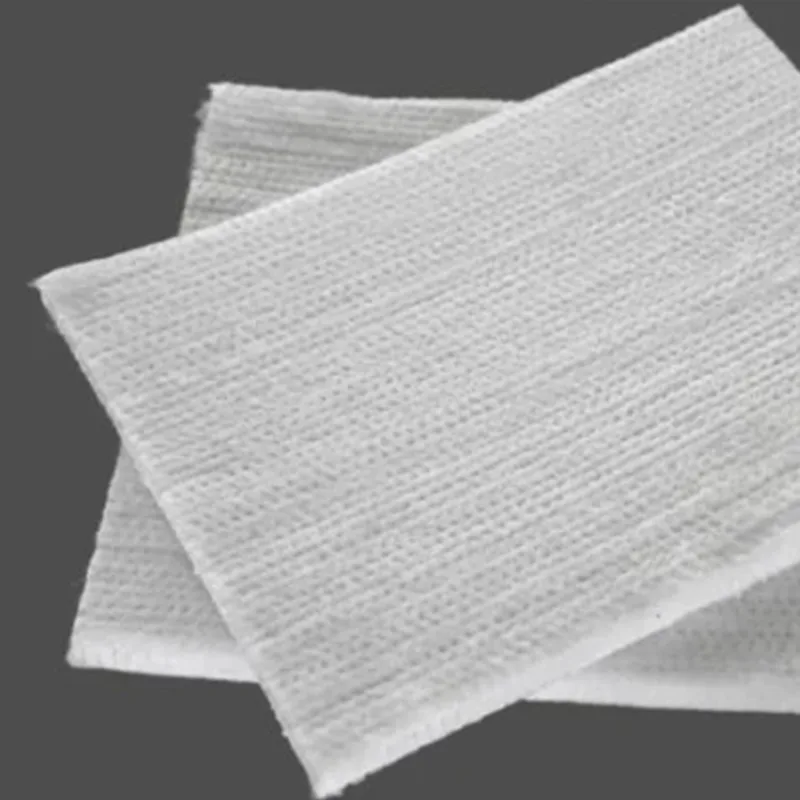

Коврик из рубленых прядей

Chopped felt is made from glass fiber strands bonded with powder or emulsion adhesive. It is primarily used for processing and manufacturing fiberglass products through hand lamination, fiber winding, and molding techniques.

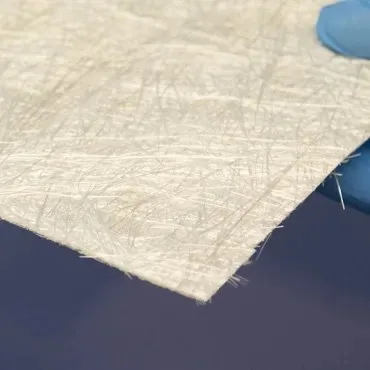

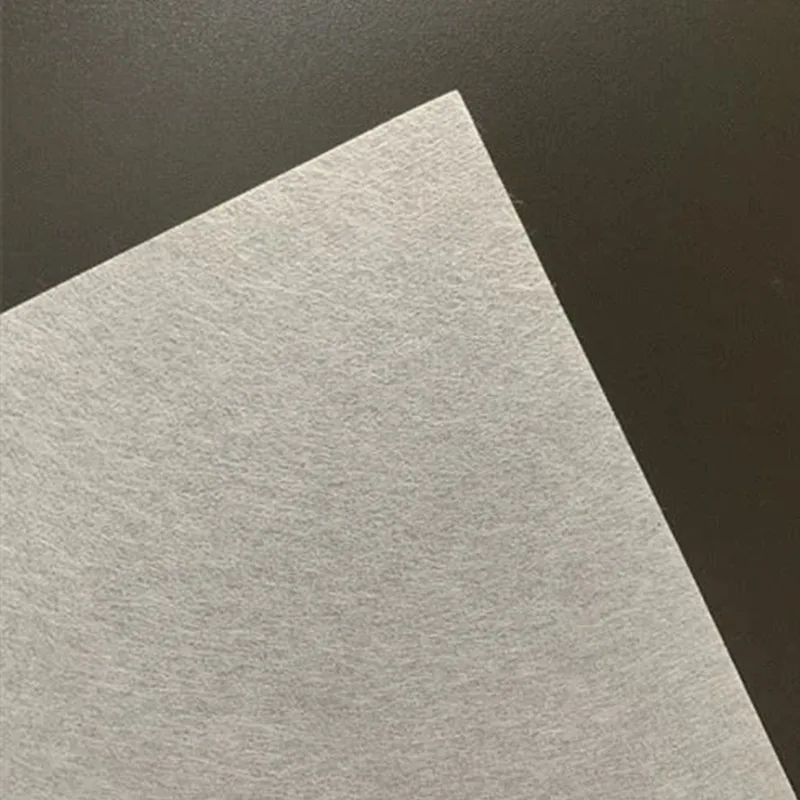

Поверхностная ткань из стекловолокна

Glass fiber surface paper is primarily used on the surfaces of fiberglass products. It features uniform dispersion, a flat surface, and low adhesive content and promotes quick resin infiltration and strong mold adhesion. This product significantly enhances the surface’s corrosion, pressure, and leak resistance while also offering a long service life.

Стекловолоконный игольчатый коврик

Игольчатый войлок из стекловолокна идеально подходит для изоляции различных нагревательных элементов в трубопроводах благодаря своим микропористым и изоляционным свойствам. Кроме того, благодаря своим фильтрующим и звукопоглощающим свойствам он служит глушителем и пылесборником для бензиновых двигателей автомобилей и мотоциклов. Этот материал широко используется для звукоизоляции, влагоизоляции, предотвращения пожаров и т. д.

Комбинированный коврик из стекловолокна

Композитные накладки из стекловолокна обычно изготавливаются из стекловолоконных нитей, сплетенных в определенных направлениях или сшитых вместе с другими стекловолоконными тканями для достижения определенных целей. В зависимости от области применения, они могут иметь приоритет мягкости или прочности. В ассортименте представлены комбинированные подушечки без скручивания, комбинированные подушечки типа "сэндвич", комбинированные подушечки со стежками, пушистые фильтрующие подушечки и комбинированные подушечки с иглами.

Boost Your Business With Custom Fiberglass Mat

NQ provides comprehensive fiberglass mat industry solutions. Our high-quality fiberglass mat guarantees the monitoring and quality inspection of the entire process, from raw materials to production to shipment. Ensure that our professional-grade fiberglass mat enhances your brand.

Настройка цвета

We offer various color options, including черный, белый, желтый, оранжевый, синий, metallic colors like gold and silver, and various vibrant, unique colors. We can customize colors to meet your specific needs and project preferences. Please feel free to contact us if you have any requirements.

Binder Customization

Short-cut chopped strands generally come in two bonding materials: emulsion and powder. Both have advantages. Emulsion-bonded chopped strands appear smoother and have a better shape, with fewer loose fibers, making them recommended by manufacturers. They are typically used in large products with fewer contours. On the other hand, powder-bonded chopped strands can disperse during cutting and are more suitable for complex structures like molds.

Персонализация упаковки

We use heat-shrinkable film for inner packaging, PE bags for individual rolls, and cardboard boxes or plastic woven bags for outer packaging. This ensures moisture protection and safeguards the products during transportation and storage. Additionally, we offer customized packaging options to meet our customers’ specific needs.

Fiber Glass Mat Specifications

Our fiberglass mat is available in various specifications to match your project requirements. Please contact us for specific parameters to ensure optimal performance and meet your unique needs.

Место происхождения | Цзянсу, Китай |

Тип коврика | Коврик для отбивки стежков |

Тип стекловолокна | E-glass, S-glass, C-glass and AR-glass, etc |

Мягкость | Мягкий |

Название бренда | NQ |

Area Weight | 250±13g/㎡,300±20g/㎡,450±20g/㎡,625±25g/㎡,900±30g/㎡,1250±40g/㎡,etc |

Тип переплета | Порошок/эмульсия |

Совместимые смолы | Смолы UP, VE, EP, PF |

Прочность на разрыв | 90-250 N |

Содержание влаги | ≤0,2% |

Контейнер 40FT | 20 тонн |

Контейнер 20 футов | 10 тонн |

Ширина | 50-3200 мм |

Содержание переплета | 2-13% |

Название предмета | Стекловолокно рубленые пряди матирования, кровельные стекловолокна маты, стекловолокна трикотажные комбо маты, стекловолокна тканые ровинга комбо маты, стекловолокна поверхности маты, стекловолокна ткани препрег |

Цвет | белый, черный, серый и т.д. |

Приложение | Гидроизоляция, изоляция и укрепление конструкций зданий; облегчение веса автомобилей, кораблей; промышленная фильтрация, изоляционные материалы; стимулирование роста растений; улучшение характеристик материалов |

Продукт | Стекловолоконные маты |

Технические характеристики | 100/120/150/225/300/380/450/600/900gsm,Customized |

Ширина рулона | 1040/1250/1270/1500mm,Customized |

Вес рулона | 30-40 кг, на заказ |

NQ Fiberglass Mat Production Process

1. Отрежьте необработанную пряжу

We use high-quality raw fiberglass materials from the Monolith Group, the world’s largest fiberglass yarn manufacturer, including Saint-Gobain, which is 20% stronger than standard fiberglass yarn.

2. Приложение для переплета

Powders include polyester resin powder, epoxy resin powder, etc., and emulsions include polyacrylate emulsion, butadiene emulsion, etc. You can choose according to your needs.

3.Обработка роллов

The roller pressing equipment with a fully automatic integrated detection system dramatically improves production efficiency and product quality. Different types of glass fiber mats can be matched with suitable equipment according to your specific needs and processing characteristics.

4. Сушильная обработка

An oven is used to dry out excess moisture and bond the glass fibers together. By carefully controlling temperature and time, the humidity can be precisely evaporated while minimizing the risk of thermal damage to the material.

5. Сухая обрезка

Once the mat has cured, we utilize state-of-the-art trimming equipment to trim it to size and remove any irregular edges or excess material. Ensure the cut.

6.Обработка упаковки

A thorough quality inspection is then carried out at the end to check for defects such as uneven thickness, delamination, or foreign matter. Once the felt meets quality standards, it is packaged and prepared for shipment.

SF

Склад и завод

Общий годовой доход

Квалифицированный рабочий

Partner With NQ To Elevate Your Project To Success

Premium quality: We have 35 production lines, using high-quality fiberglass raw materials and passing multiple quality inspection processes to ensure that each roll of fiberglass blanket meets international standards.

Competitive price: With our strong production capacity and raw material procurement advantages, we can provide cost-effective products to help you reduce production costs while maintaining high quality.

Fully Customize: We provide comprehensive customization services and can adjust specifications, thickness, density, etc., according to your specific needs to ensure that the needs of different application scenarios are perfectly met.

Сертификат

The Advantage Of The Fiberglass Mat

As a senior purchasing manager in the construction industry, I recognize the importance of quality materials for project success. Since partnering with this fiberglass mat manufacturer, I’ve gained confidence in their products. Made from premium raw materials, their mats are durable, weather-resistant, and stable in extreme conditions. The consistent quality across batches reduces risks and uncertainties. Additionally, their products offer great value, helping us save on procurement costs and reallocate resources effectively.

Уильям Бейкер

Предприниматель

In automotive manufacturing, material choice impacts performance, safety, and durability. The fiberglass mats from this manufacturer have exceeded our expectations. Their strength, toughness, and stability are industry-leading, ensuring excellent performance in complex environments. Their competitive pricing helps us manage costs without compromising quality. Additionally, their after-sales service and technical support are top-notch, resolving issues quickly. I’m delighted with this partnership and look forward to continuing it.

Оливер Беннетт

Предприниматель

Shipbuilding demands high-performance materials, and this manufacturer’s fiberglass mats meet our needs perfectly. Their mats offer excellent fire and waterproof properties, protecting ship structures from damage. They are lightweight yet strong, reducing the ship’s overall weight and improving efficiency. Their competitive pricing helps manage procurement costs while ensuring quality. Additionally, they provide tailored solutions and emphasize strong customer collaboration. I’m delighted with this partnership and look forward to continuing our work together.

Сэмюэл Карлсон

Предприниматель

The Advantage Of The Fiberglass Mat

Our expertise in fiberglass blanket manufacturing has made us one of China’s most trusted fiberglass blanket manufacturers. With our advanced production facilities, we provide high-quality fiberglass blankets to customers worldwide and meet the needs of various industrial applications. Our fiberglass blanket products can help customers effectively reduce costs and meet the needs of bulk purchases. The fiberglass blankets we provide have the following advantages:

Быстрое увлажнение

Смола быстро проникает в материал. Оптимизируя поверхностную энергию, структуру пор и другие рабочие параметры, мы можем увеличить скорость проникновения и равномерность смолы, тем самым улучшая общие характеристики и надежность композита.

Хорошая однородность

Fiberglass pads can be held closely to objects. Uniform fiber distribution, pore structure, and consistent resin penetration provide a tight fit to the object, allowing for more efficient processing.

Не поддается коррозии

Glass fiber mats are corrosion-resistant, chemically stable, and can effectively resist the erosion of various corrosive media, ensuring that your equipment or structure can operate reliably for a long time, even in harsh environments.

Термостойкость и устойчивость к плесени

Мат из стекловолокна обладает впечатляющими теплоизоляционными свойствами и устойчивостью к плесени. Он эффективно блокирует теплопроводность, обеспечивая превосходный теплоизоляционный эффект. Кроме того, он противостоит образованию плесени, сохраняя сухость и чистоту, что продлевает срок его службы.

Совместимость

Glass fiber felt is compatible with various resin materials, including polyester, vinyl ester, and epoxy resin. This compatibility allows it to form composite materials with high strength, modulus, corrosion resistance, and wear resistance. As a result, it offers more options for your projects.

Простой в обращении

Using or installing fiberglass mats is straightforward. Their excellent flexibility allows them to be easily adapted for installation on complex shapes and surfaces without complicated preconditioning or cutting, simplifying the process.

Стекловолокнистые маты по GSM или OZ

GSM (grams per square meter) or OZ (ounces per square foot) is an essential parameter for selecting fiberglass mats. There are 1,5 унции, 2 унции, 100 г, 300 г, 450 г, 600 г и т.д.. It directly determines the thickness of the glass fiber in the mat. Choose the appropriate fiberglass mat in combination with the application field. Как правило, низкий GSM обладает лучшей смачиваемостью и однородностью, а высокий GSM - более толстыми слоями и высокой прочностью.

1.5 oz Fiberglass Mat

Weight: 1.5 ounces per square foot

A 1.5 oz fiberglass mat means that each square yard weighs 1.5 ounces (about 42.5 grams). This material consists of non-woven glass fibers and is commonly used to reinforce structures and provide additional strength and durability. It is often combined with resins or other reinforcing materials and is widely used to manufacture composite materials.

2 oz Fiberqlass Mat

Weight: 2 ounces per square foot

2 oz fiberglass mat is sold in continuous 50″ wide rolls and is suitable for use as a reinforcement material or surface treatment material. Its thinness makes it unsuitable for structural repairs as it does not provide sufficient strength; however, you can achieve the desired thickness and strength by stacking multiple layers if necessary.

100g Fibreglass Matting

Weight:100g per square meter

100g fiberglass mat is usually used with resin, with fast wet, good transparency, and apparent effect after drying. It is relatively thick and is one of the thickest of all surface materials. The standard width is 1270mm, which is widely used on various occasions that require enhanced strength and durability.

450g Fibreglass Matting

Weight: 450g per square meter

The 450g fiberglass mat has fast moisture absorption, allowing it to quickly interact with water and promote adhesive dissolution, helping accelerate the curing process. It is widely used in industries such as construction, automotive, and shipbuilding to enhance the strength and stability of composite materials.

600g fibreglass Matting

Weight: 600g per square meter

The 600g fiberglass mat provides uniform strength in all directions, ensuring consistent performance of composite materials under different load directions. It is suitable for high-strength and high-durability applications in construction, automotive, and shipbuilding industries.

Chopped Strand Mat By GSM or OZ

GSM (grams per square meter) or OZ (ounces per square yard) is essential when selecting Chopped Strand Mat. The choice should be based on the specific application. Lower GSM/OZ offers better penetration but may not cover the underlying surface adequately. On the other hand, higher GSM/OZ ensures improved stability and stiffness.

1.5 oz Chopped Fiberglass Mat

Weight: 1.5 ounces per square foot

The 1.5-ounce chopped fiberglass mat is commonly used with epoxy resin to increase the thickness of parts or molds quickly. It can be used as an interlayer material or on its own, and workers often tear the fibers during application to enhance the bonding effect.

2 oz Chopped Fiberglass Mat

Weight: 2 ounces per square foot

The 2 oz chopped mat is made from medium-fine fibers and chopped glass filaments bonded with polyester powder or emulsion. When resin is applied, it quickly dissolves the binder and absorbs the resin, becoming transparent and durable after drying. It is suitable for enhancing the strength and thickness of composite materials.

3 oz Chopped Fiberglass Mat

Weight: 3 ounces per square foot

The 3 oz chopped fiberglass mat is bonded with adhesive and comes in powder or emulsion forms. It is suitable for quickly increasing thickness but is not recommended for thick layers due to lower durability than higher GSM materials. It performs better on curved surfaces or small corners and is easy to cut or tear, making it convenient.

CSM 300 Fiberglass Mat

Weight: 300g per square meter

CSM 300 fiberglass mat is one of the most popular products, with bundles of glass filaments bonded by powder or emulsion. When the polyester resin is applied, the binder dissolves, making the mat soft enough to conform to different contours and surfaces closely. However, it is most effective and economical when used to build up the body and thickness, providing enhanced strength.

CSM 450 Fiberglass Mat

Weight: 450g per square meter

CSM 450 fiberglass mat is made from alkali-free chopped glass fibers bonded with powder or emulsion, typically used with resin to dissolve the binder and soften the mat. It is especially suitable for hand lay-up and winding processes and is widely used in building structures, providing high strength and durability.

Fiberglass Mat By Different Applications

Due to its strength and durability, fiberglass mat is used in various industries. In construction, it’s used to reinforce concrete and create composite materials. In the automotive and marine industries, it’s used to make lightweight, strong parts like body panels and boat hulls. It’s also used in wind energy to reinforce blades, electronics to insulate, and industrial applications to make molds and durable parts.

Flooring Tissue

The S-FLM series mat is mainly used as a soft plastic flooring and wallpaper substrate. It features a smooth surface, no deformation, vibrant colors, and easy installation, making it an ideal material for residential flooring decoration. After further processing, it can be made into various colored laminates, making it perfect for decorating high-end hotels and stores.

Carpet Tissue

The carpet felt series is mainly used as the substrate for carpet tiles. Carpet tiles made from fiberglass felt have a firm appearance, do not shrink or deform and are ideal for indoor floor decoration.

PCB(Printed Circuit Board )Tissue

PCB electronic felt is a key material for CEM-3 production. Our E-glass electronic products, developed in China, are used in CEM-3 steel plates. Tests show our fiberglass paper meets or exceeds import standards, has superior heat resistance, and is widely used in high-frequency and LED applications.

Insulation Tissue

Insulation felt is a high-quality material made from short-cut glass fibers using a wet-forming process. It has good fiber distribution, uniform thickness, high-temperature resistance, and low thermal conductivity, ensuring excellent insulation. The product is easy to install, energy-efficient, cost-effective, and suitable for waterproofing, underground pipelines, and interior and exterior applications.

Battery separator tissue

The separator felt is primarily used as the base material for lead-acid battery separators. The composite separators with S-BM offer good vibration resistance and mechanical strength, resulting in batteries with strong starting power and a longer lifespan.

Roofing Tissue/Pipe Tissue

S-RM series felt is used to make modified asphalt waterproofing membranes and glass fiber shingles, which can improve weather resistance and impermeability and extend service life. It is suitable for roofing and insulation layers. S-PM series felt is used for underground pipeline waterproofing, has excellent resistance to environmental factors, extends pipeline life, and reduces maintenance costs.

Application Of Glass Fiber Mat

Fiberglass mat is a versatile material used in construction for reinforcement, automotive manufacturing for lightweight parts, shipbuilding for durable, corrosion-resistant components, and sports equipment for strength and performance. It’s also widely used for electrical insulation due to its heat and resistance.

Химическая инженерия

In chemical engineering, fiberglass mat is used for lining pipes, containers, and tanks, offering corrosion and heat resistance, and coatings and reinforcement in reactors.

- Толщина: 1.5-4mm

- Плотность: 250-600g/m²

- High-temperature resistance: 300℃

- Corrosion resistance: Strong

Строительная промышленность

In construction, fiberglass mat reinforces plastering, walls, and flooring, offering strength, durability, and crack resistance. It also enhances roofing stability.

- Толщина: 1.5-4mm

- Плотность: 250-600g/m²

- High-temperature resistance: 200-300℃

- Corrosion resistance: Excellent

Спорт и досуг

In sports and leisure, fiberglass mats are used in equipment like surfboards, skateboards, and bicycles for their light weight, strength, and durability, improving performance and resistance to wear.

- Толщина: 1.5-3mm

- Плотность: 200-400g/m²

- High-temperature resistance: 150-250℃

- Corrosion resistance: Good

Электронная и электрическая промышленность

In the electronics and electrical field, fiberglass mat is used for insulation in components like transformers and circuit boards, offering high-temperature resistance and electrical insulation.

- Толщина: 0.8-2mm

- Плотность: 200-400g/m²

- High-temperature resistance: 180-250℃

- Corrosion resistance: Excellent

Frequently Asked Questions

Below you can find some frequently asked questions about shipment and MOQ. If you have any further questions, please feel free to contact us.

Какова ваша MOQ?

Наш MOQ обычно составляет 1x20ft контейнер. Но мы принимаем меньшее количество для вашего пробного заказа. Пожалуйста, не стесняйтесь сообщить нам ваш план для

покупая, мы предложим цену, соответствующую вашему количеству. И мы надеемся, что вы увеличите количество заказов после того, как вы проверите наши

качество продукции и узнать о наших услугах.

Какой порт отгрузки?

Мы отправляем товары через порт Шанхая.

Сколько цветов в наличии?

Мы можем сделать пользовательский цвет, когда достичь нашего MOQ qty.

Наши обычные цвета: белый, желтый, зеленый, синий, оранжевый, красный и т.д.

Какой формат файла вам нужен, если я хочу сделать свой собственный дизайн?

Для печати дизайна этикетки нам нужен файл AI или PDF для создания печатного шаблона.

Каков срок доставки?

Время доставки составляет около 20 ~ 30 дней после получения депозита.

Каково время выборки?

Обычно на изготовление образцов уходит 7-10 дней.

Какой способ доставки доступен?

По морю до назначенного порта.

Какой способ оплаты является приемлемым?

1. Безотзывный аккредитив, наличные, PayPal, кредитная карта и денежные переводы T/T.

2.30% T/T депозит заранее, 70% баланс перед отгрузкой после представления готового груза.

3.L/C (безотзывный аккредитив по предъявлении)

Если вам нужен пользовательский размер, такой как вес грамма и размер ячейки и т.д. или частный логотип, пожалуйста, не стесняйтесь запрашивать нас!

Fiberglass Mat FAQ

Для чего используется стекловолоконный мат?

A fiberglass mat is a non-woven fabric made by interweaving fiberglass filaments into a mesh structure, which are bonded together through chemical adhesives or mechanical means.

Its main uses include:

- Reinforcement of Composite Materials: Fiberglass mat is commonly used to reinforce composite materials like unsaturated polyester and epoxy resin, enhancing their strength and rigidity.

- Hand Lay-Up Process: A fiberglass mat is used to strengthen resin-based composite materials in hand lay-up molding.

- Pultrusion Process: A fiberglass mat is used in the extrusion process to enhance the longitudinal and transverse strength of products and prevent cracking.

- Thermal Insulation: Fiberglass mat has excellent thermal insulation properties and is widely used in construction, shipbuilding, automotive, and other fields for thermal insulation.

- Filtration Material: Fiberglass mat is used in air and liquid filters due to its good filtration performance.

- Sound Insulation and Noise Reduction: Fiberglass mat is used in the automotive industry for sound insulation, noise absorption, vibration reduction, and fire resistance.

- Roof Waterproofing: Fiberglass mat is the substrate used for roofing waterproofing membranes due to its excellent properties.

In conclusion, fiberglass mats are widely used in various fields, such as composite material reinforcement, thermal insulation, filtration, sound insulation, and roof waterproofing.

Что лучше, стекловолоконный мат или ткань?

Here’s a comparison table of fiberglass mat vs fiberglass cloth:

| Характеристика | Стекловолоконный мат | Стекловолоконная ткань |

|---|---|---|

| Manufacturing Process | Made from randomly bonded short glass fibers. | Made from woven continuous glass fibers. |

| Strength | Generally lower tensile strength compared to cloth. | Higher tensile strength due to its woven structure. |

| Гибкость | More flexible, adapts easily to irregular shapes. | Less flexible, best for flat or structured surfaces. |

| Surface Finish | Typically smoother, suitable for smooth surfaces. | Rougher texture, better for structural applications. |

| Вес | Heavier, used in thicker applications. | Lighter, more suitable for weight-sensitive applications. |

| Долговечность | Less durable in terms of tensile strength. | More durable, especially in high-stress applications. |

| Applications | Common in boat building, insulation, and surface repairs. | Used in aerospace, automotive, and high-performance applications. |

| Стоимость | Generally cheaper than fiberglass cloth. | More expensive due to higher strength and precision. |

This comparison helps in deciding which material to use depending on the specific requirements, like strength, flexibility, weight, and cost.

Для чего используется стеклоткань?

Fiberglass cloth is made from woven glass fibers. It is known for its lightweight, high strength, corrosion resistance, and high temperature resistance. It is widely used in multiple fields.

Main Uses:

- Composite Material Reinforcement: Fiberglass cloth is commonly used to reinforce composite materials, such as fiberglass, enhancing their mechanical strength and durability.

- Electrical Insulation: Fiberglass cloth is widely used in electronic products, such as circuit boards, due to its excellent electrical insulation properties.

- Строительная промышленность: In the construction field, fiberglass cloth is used for wall reinforcement, exterior wall insulation, roofing waterproofing, and enhancing materials like cement, plastic, asphalt, marble, and mosaic.

- Shipbuilding: Fiberglass cloth is widely used in hand lay-up molding for ship hulls, storage tanks, cooling towers, vehicles, and other applications.

- Автомобильная промышленность: Fiberglass cloth is used to manufacture car body parts, enhancing their strength and safety.

- Аэрокосмическая промышленность: Fiberglass cloth is used in the manufacturing of aircraft and spacecraft. It provides lightweight and high-strength properties that improve fuel efficiency and load capacity.

- Химическая промышленность: Fiberglass cloth is used to protect storage tanks and pipelines from corrosion, extending the service life of equipment.

- Electronics: Fiberglass cloth is used in electronic components for insulation and shielding, protecting components from external electromagnetic interference.

In conclusion, fiberglass cloth’s excellent performance makes it important in many fields, including composite material reinforcement, electrical insulation, construction, shipbuilding, automotive, aerospace, chemical, and electronics.

Портится ли стекловолоконный мат?

Fiberglass mat is a non-woven fabric made from glass fibers, known for its excellent high-temperature resistance, corrosion resistance, and insulation properties.

Storage Conditions:

Fiberglass mats should be stored in a dry, well-ventilated environment, away from direct sunlight and high humidity, to prevent the material from absorbing moisture or aging.

Lifespan:

With proper storage, fiberglass mat typically has a long lifespan.

Considerations:

Prolonged exposure to high temperatures, humidity, or chemically corrosive environments may degrade the performance of fiberglass mats.

Therefore, it’s recommended that it be inspected for appearance and performance before use to ensure it meets the required standards.

Сколько слоев стекловолоконного мата использовать?

The number of layers of fiberglass mat to use depends on the specific application and the desired strength. Here are some general recommendations for different fields:

Boat Building:

Fiberglass mat is commonly used in the base layers of a boat’s hull to provide strength, while fiberglass cloth is used for the surface layer for a smoother finish. The number of layers depends on the design requirements and the desired strength.

Roofing:

The number of fiberglass mat layers in roofing applications depends on the roof area and the expected usage. One layer of 450g/m² fiberglass mat is typically recommended for roofs without foot traffic. For roofs with foot traffic, one layer of 600g/m² fiberglass mat or two layers of 450g/m² fiberglass mat are recommended.

General Recommendation:

Determining the number of layers when using fiberglass mats is essential based on the specific application and design requirements. Typically, a base layer of fiberglass mat provides strength, while the surface layer uses fiberglass cloth for a smoother finish. The number of layers in roofing depends on the area and intended use.

Please note that these recommendations are general guidelines. The number of layers should be adjusted according to specific project needs and design criteria.

Можно ли использовать эпоксидную смолу на стекловолоконном мате?

Epoxy can be used on fiberglass mats. It is a significant polymer material primarily composed of epoxy resin and hardener. Epoxy exhibits excellent characteristics such as corrosion resistance, heat resistance, vibration resistance, water resistance, and strong adhesive properties. These properties make epoxy widely applicable in various fields, including construction, artificial molding, compression molding, electronics, automotive, marine, aerospace, and more.

When applied to a fiberglass mat, epoxy can enhance the mat’s strength, durability, and stability. The epoxy resin can penetrate between the fibers of the mat, forming a strong adhesive layer that improves the overall performance of the mat. Additionally, epoxy’s chemical and weather resistance can protect the fiberglass mat from environmental factors such as moisture and corrosion.

In practical applications, when treating a fiberglass mat with epoxy, the following points should be noted:

- Выберите подходящую эпоксидную смолу и отвердитель: Убедитесь, что выбранные эпоксидная смола и отвердитель совместимы со стекловолоконным матом и соответствуют требуемым эксплуатационным характеристикам.

- Правильная пропорция смешивания: Следуйте инструкциям производителя для правильного смешивания эпоксидной смолы и отвердителя, чтобы обеспечить оптимальные характеристики отверждения.

- Унифицированное приложение: Равномерно нанесите смешанную эпоксидную смолу на стекловолоконный мат, избегая пузырей и незакрытых участков.

- Условия отверждения: To achieve the best curing effect, ensure that the epoxy cures under appropriate conditions, such as temperature, humidity, and time.

- Меры предосторожности: Epoxy may release harmful gases during the curing process, so it should be handled in a well-ventilated environment, and appropriate personal protective equipment should be worn.

Essentially, epoxy can be used on fiberglass mats to enhance their performance and service life. During application, attention should be paid to selecting the appropriate epoxy and hardener, proper mixing ratio, uniform application, curing conditions, and safety precautions.

Что лучше, стекловолоконный мат или ткань?

Regarding the question of which is better, fiberglass mat or fiberglass cloth, there is no absolute answer as they each have different characteristics and advantages that suit different application scenarios.

FeatureFiberglass MatFiberglass Cloth

Материал Made of chopped strands of glass fibers, randomly oriented. Made of woven glass fibers arranged in a structured pattern.

Strength Provides moderate strength but less than fiberglass cloth. Offers higher strength due to the woven structure.

Гибкость: It is more rigid and suitable for flat or slightly curved surfaces. It is more flexible and ideal for tight curves and complex shapes.

Вес Heavier compared to cloth of the same thickness. Lighter than mat for the same thickness.

Wet-Out Quality: It may not wet out as quickly or clearly with epoxy; it requires more resin. It wets out well with epoxy, providing a more precise finish.

Долговечность Generally durable but may have slightly lower strength. It is more durable and long-lasting due to the woven structure.

Applications Ideal for basic reinforcement, hulls, and areas with minimal flex. Used for high-strength applications such as automotive and aerospace.

Стоимость Usually less expensive. Generally, it is more costly due to the woven fibers.

Ease of Используйте: It is easier to work with for more extensive, flat surfaces. Requires more precision and skill, especially for curves.

Отделка: Less smooth finish, often requires sanding. Smooth and finer finish, ideal for a clean surface.

Стекловолоконный мат

Характеристики и преимущества:

- Гибкость: Fiberglass mats generally have good flexibility, making them easy to handle and install, incredibly when filling irregular surfaces or gaps.

- Поглощение влаги: Некоторые стекловолоконные маты после специальной обработки могут обладать хорошими влагопоглощающими свойствами, что может улучшить характеристики материала в конкретных областях применения.

- Экономическая эффективность: По сравнению с некоторыми видами стеклоткани стекловолоконные маты могут предложить более выгодную стоимость, особенно для крупномасштабного применения.

- Арматура: When used as a base layer for coatings, putties, gypsum, and other materials, fiberglass mats can significantly improve surface strength and durability and prevent cracking.

Стекловолоконная ткань

Характеристики и преимущества:

- Высокая прочность: Fiberglass cloth typically has high tensile and bending strengths and can withstand significant forces, making it suitable for high-strength support applications.

- Устойчивость к коррозии: Обладает хорошей устойчивостью к большинству химических сред и может использоваться в течение длительного времени в кислой или щелочной среде.

- Термостойкость: It has excellent high-temperature performance and can be used for extended periods in high-temperature environments.

- Свойства изоляции: Это отличный изоляционный материал с хорошими электро- и теплоизоляционными свойствами.

- Универсальность: Стекловолокнистая ткань поставляется в различных вариантах плетения и спецификациях, таких как полотняное, саржевое и двунаправленное плетение, удовлетворяя различные потребности промышленности.

Сравнение сценариев применения

- Строительная промышленность: Fiberglass mats are often used for wall insulation and surface reinforcement, while fiberglass cloth is more suitable for reinforcing building structures, roof repairs, and other high-strength support applications.

- Аэрокосмическая промышленность: Both may be used in the manufacture and repair of aircraft, rockets, and other aerospace vehicles, but the specific choice depends on the required performance and design specifications.

- Автомобильная промышленность: Fiberglass cloth is more commonly used to manufacture and repair automotive parts, such as bodies and engine covers.

Заключение

In summary, fiberglass mats and fiberglass cloth each have their own merits, and the choice of which is better depends on the specific application scenario and requirements. Fiberglass mats may be more suitable when flexibility, cost-effectiveness, or specific moisture absorption properties are needed. On the other hand, fiberglass cloth may excel when high strength, corrosion resistance, heat resistance, or insulation properties are required. Therefore, one should consider the actual needs and application environment when choosing.

Насколько прочен стекловолоконный мат?

There is no absolute answer to the question of which is better, fiberglass mat or fiberglass cloth, as they each have different characteristics and advantages that suit different application scenarios.

FeatureFiberglass MatFiberglass Cloth

Материал Made of chopped strands of glass fibers, randomly oriented. Made of woven glass fibers arranged in a structured pattern.

Strength Provides moderate strength but less than fiberglass cloth. Offers higher strength due to the woven structure.

Гибкость: It is more rigid and suitable for flat or slightly curved surfaces. It is more flexible and ideal for tight curves and complex shapes.

Вес Heavier compared to cloth of the same thickness. Lighter than mat for the same thickness.

Wet-Out Quality: Epoxy may not wet out as quickly or clearly; it requires more resin. However, epoxy wets out well, providing a more precise finish.

Долговечность Generally durable but may have slightly lower strength. It is more durable and long-lasting due to the woven structure.

Applications Ideal for basic reinforcement, hulls, and areas with minimal flex. Used for high-strength applications such as automotive and aerospace.

Стоимость Usually less expensive. Generally, it is more costly due to the woven fibers.

Ease of Use: It is easier to work with for more extensive, flat surfaces. Requires more precision and skill, especially for curves.

Отделка: Less smooth finish, often requires sanding. Smooth and finer finish, ideal for a clean surface.

Стекловолоконный мат

Характеристики и преимущества:

- Гибкость: Fiberglass mats generally have good flexibility, making them easy to handle and install. This makes them incredibly useful when filling irregular surfaces or gaps.

- Поглощение влаги: Некоторые стекловолоконные маты после специальной обработки могут обладать хорошими влагопоглощающими свойствами, что может улучшить характеристики материала в конкретных областях применения.

- Экономическая эффективность: По сравнению с некоторыми видами стеклоткани стекловолоконные маты могут предложить более выгодную стоимость, особенно для крупномасштабного применения.

- Арматура: Fiberglass mats can significantly improve surface strength and durability and prevent cracking when used as a base layer for coatings, putties, gypsum, and other materials.

Стекловолоконная ткань

Характеристики и преимущества:

- Высокая прочность: Fiberglass cloth typically has high tensile and bending strengths and can withstand significant forces, making it suitable for high-strength support applications.

- Устойчивость к коррозии: Обладает хорошей устойчивостью к большинству химических сред и может использоваться в течение длительного времени в кислой или щелочной среде.

- Термостойкость: It has excellent high-temperature performance and can be used for extended periods in high-temperature environments.

- Свойства изоляции: Это отличный изоляционный материал с хорошими электро- и теплоизоляционными свойствами.

- Универсальность: Стекловолокнистая ткань поставляется в различных вариантах плетения и спецификациях, таких как полотняное, саржевое и двунаправленное плетение, удовлетворяя различные потребности промышленности.

Сравнение сценариев применения

- Строительная промышленность: Fiberglass mats are often used for wall insulation and surface reinforcement, while fiberglass cloth is more suitable for reinforcing building structures, roof repairs, and other high-strength support applications.

- Аэрокосмическая промышленность: Both may be used in the manufacture and repair of aircraft, rockets, and other aerospace vehicles, but the specific choice depends on the required performance and design specifications.

- Автомобильная промышленность: Fiberglass cloth is commonly used to manufacture and repair automotive parts, such as bodies and engine covers.

Заключение

In summary, fiberglass mats and fiberglass cloth each have their own merits, and the choice of which is better depends on the specific application scenario and requirements. Fiberglass mats may be more suitable when flexibility, cost-effectiveness, or specific moisture absorption properties are needed. On the other hand, fiberglass cloth may excel when high strength, corrosion resistance, heat resistance, or insulation properties are required. Therefore, one should consider the actual needs and application environment when choosing.

Является ли стекловолоконный мат водонепроницаемым?

Fiberglass matting is не является водонепроницаемым по своей сути, but it can become waterproof when combined with waterproof resin or other coatings. Here’s how it works:

- Fiberglass Matting Characteristics:

- A fiberglass mat is made from chopped glass fibers bonded with a binder. While the matting does not naturally repel water, it is resistant to moisture and will not degrade or dissolve in the presence of water, unlike some other materials.

- Waterproofing with Resin:

- Fiberglass matting is typically used with a waterproof resin, such as epoxy resin, polyester resin, or vinyl ester resin, to make waterproof matting. The resin binds the fiberglass fibers together and fills the spaces between them, creating a waterproof barrier.

- Epoxy resin, in particular, is known for its excellent water resistance and is often used for applications that require waterproofing, such as in boat building, roofing, and waterproof coatings.

- Applications:

- When fiberglass matting is used with resin in applications like boat hulls, waterproof roofing, or waterproof barriers in construction, it forms a strong, durable, and waterproof layer that resists water infiltration.

- In roofing systems, fiberglass mat is often used as part of a multi-layer system, providing structural reinforcement and helping maintain a waterproof surface.

- Environmental Resistance:

- Fiberglass matting is highly resistant to moisture and water over time, as the glass fibers do not absorb water. However, the matting alone would not provide full waterproofing without proper resin treatment.

Conclusion:

Fiberglass matting is not waterproof by itself, but when combined with a suitable waterproof resin, it can become waterproof, making it ideal for applications where moisture and water resistance are crucial.

Почему люди используют стекловолокно?

People use fiberglass for a wide range of applications due to its unique combination of properties that make it highly versatile. Here are the key reasons why fiberglass is widely used:

1. High Strength-to-Weight Ratio

- Fiberglass is lightweight but strong, making it ideal for applications where strength and weight are essential. It is more potent than many metals (like aluminum) and is much lighter, which is why it’s used in the automotive, aerospace, and marine industries.

2. Устойчивость к коррозии

- Fiberglass is highly resistant to chemical, moisture, and environmental corrosion. This makes it an excellent material for harsh environments, such as marine vessels, chemical tanks, и construction (e.g., roofing, pipes).

3. Долговечность

- Fiberglass is durable and long-lasting. It can withstand extreme temperatures and physical wear, making it suitable for indoor and outdoor applications.

4. Свойства изоляции

- Fiberglass is an excellent thermal and electrical insulator. It’s commonly used for insulation in buildings (e.g., fiberglass insulation batts), electrical components, and applications requiring resistance to temperature changes.

5. Flexibility and Molding Capabilities

- Fiberglass can be easily molded into complex shapes, making it highly versatile for various industries. It is often used in molding applications to create custom parts for the automotive, aerospace, and construction industries.

6. Lightweight and Cost-Effective

- Compared to metals like steel or aluminum, fiberglass is often more cost-effective and provides significant weight savings, a critical factor in many industries, such as automotive manufacturing and boat building.

7. Water Resistance

- Fiberglass is inherently water-resistant; it forms a strong, waterproof barrier when combined with resin. This makes it ideal for boat hulls, swimming pools, и waterproof coatings in construction.

8. Reinforcement Material

- Fiberglass is often used as a reinforcing material in composite structures. Combined with resins (like epoxy or polyester), it creates strong, durable composite materials used in aerospace, construction, и automotive manufacturing.

9. Fire Resistance

- Fiberglass is non-combustible and has excellent fire-resistant properties, making it an essential material for applications requiring fireproofing, such as construction, electrical systems, и protective gear.

10. Ease of Maintenance

- Products made with fiberglass are often easy to maintain, resistant to UV degradation, and do not require frequent replacements. This makes it ideal for outdoor equipment, automobiles, и construction materials.

Summary:

Fiberglass is used for its прочность, lightweight nature, corrosion resistance, durability, и insulating properties. It is a key material in various industries, including construction, marine, automotive, aerospace, и insulation.

Для чего используются стекловолоконные маты?

Fiberglass matting is a versatile material used in various applications due to its strength, durability, and resistance to environmental factors. Here are some common uses of fiberglass matting:

1. Boat Building and Marine Applications

- Fiberglass matting is commonly used in boat hulls and marine structures to provide strength and resistance to water. Combined with resin (such as polyester or epoxy), it forms a rigid, waterproof layer ideal for boat construction and repair.

2. Roofing and Waterproofing

- In roofing systems, fiberglass matting is used as a base layer in waterproofing membranes. It helps reinforce roofing systems, preventing leaks and ensuring long-lasting protection against moisture.

3. Автомобильное производство

- Fiberglass matting is used in automotive parts like body panels, fenders, and interior components. It provides strength and impact resistance while reducing weight, making it a key material in the automotive industry for creating durable, lightweight components.

4. Construction and Reinforcement

- Fiberglass matting is often used to reinforce materials such as concrete or plaster. It helps improve the structural integrity and durability of walls, ceilings, and floors, particularly in drywall applications or when reinforcing masonry walls.

5. Pipes and Tanks

- Used to reinforce pipes and storage tanks, fiberglass matting provides resistance to corrosion and impact. It’s commonly employed in industries where chemicals are transported or stored, such as chemical processing plants.

6. Swimming Pools

- In swimming pool construction and repairs, fiberglass matting is often applied as part of a multi-layer system to create a durable, water-resistant finish. It helps ensure that the pool structure is strong, resistant to cracking, and easy to maintain.

7. Лопасти ветряных турбин

- Fiberglass matting is used to manufacture wind turbine blades due to its strength-to-weight ratio, making it an ideal material for large, lightweight, yet strong structures that can withstand harsh weather conditions.

8. Insulation

- Fiberglass matting is often used in thermal and acoustic insulation applications. It can be found in buildings and vehicles as a material to reduce heat transfer and dampen sound, improving overall comfort and energy efficiency.

9. Waterproofing Fabrics

- Fiberglass matting is used as a reinforcing layer in waterproof fabrics and membranes, providing added durability for outdoor gear, such as tents, tarps, and protective covers.

10. Reinforced Plastic Composites

- Fiberglass matting is a key component in creating fiberglass-reinforced plastic composites. These composites are used in a wide range of applications, such as industrial tanks, pipes, bathtubs, и countertops, due to their strength, resistance to chemicals, and ease of maintenance.

11. Fireproofing

- Fiberglass matting is sometimes used in fireproofing applications, as it is non-combustible and offers fire-resistant properties. It can be integrated into fire-resistant panels and insulation systems to protect buildings and infrastructure.

Summary:

Fiberglass matting is widely used in marine, automotive, construction, roofing, и insulation industries due to its прочность, water resistance, corrosion resistance, и versatility. It is a critical material in products and applications that require reinforcement, durability, and protection from the elements.

Теряет ли стекловолоконная изоляция R-value со временем?

The R-value of fiberglass insulation does not significantly decrease over time under normal circumstances. The R-value is an essential metric for measuring the thermal insulation performance of a material, reflecting its ability to resist heat flow.

The R-value of fiberglass insulation is primarily determined by factors such as the material’s thickness, density, and fiber structure. These factors are established during the material’s manufacturing process and remain relatively stable during use without significant changes over time.

However, it should be noted that if the fiberglass insulation is damaged during installation or use, such as being compressed, torn, or exposed to moisture, these factors may affect its insulation performance, decreasing the R-value. Additionally, if the material is exposed to extreme temperatures or humidity for prolonged periods, it may have a minor impact on its performance, but this impact is usually not significant enough to cause a substantial reduction in R-value.

To maintain the good performance of fiberglass insulation, the following points are recommended during use:

- Ensure that the material is not damaged during installation and that its original thickness and density are maintained.

- Не подвергайте материал длительному воздействию экстремальных температур или влажности, чтобы минимизировать влияние на его характеристики.

- Regularly inspect the integrity and performance of the insulation system to identify and repair any potential issues promptly.

In summary, the R-value of fiberglass insulation does not significantly decrease over time under normal circumstances, but care should be taken to protect the material from damage and avoid exposing it to extreme environments that may affect its performance.

Что произойдет, если смола для стекловолокна намокнет?

Under normal circumstances, fiberglass insulation’s R-value rings to a composite material combining fily resin material; here, it is assumed to mean fiber material’s-ass-reinforced resin-based compete; the impact depends on the specific type of resin, the structure of the composite, and the duration of water exposure. Below are some possible scenarios:

- Тип смолы:

- Ненасыщенная полиэфирная смола: This resin type is relatively sensitive to moisture before curing. The presence of water can lead to incomplete curing reactions or the formation of bubbles, which can affect the strength and appearance of the composite.

- Эпоксидная смола: Epoxy resin also has a particular sensitivity to moisture before curing, but it is generally less significant than that of unsaturated polyester resin. However, if the resin is still in a liquid state and uncured, the mixing of water can interfere with the curing process, resulting in incomplete curing, surface defects (such as cloudiness, white or hazy areas, ripples, waves, depressions, and spot marks), and reduced performance after curing.

- Термореактивная смола: Once cured, most thermosetting resins (including fiberglass-reinforced resin-based composites) are highly resistant to moisture and will not be significantly affected by short-term exposure to water.

- Композитная структура:

- If water can penetrate between the composite’s internal layers, it may weaken the interlayer bonding and even cause delamination.

- Damage to the composite’s surface protective layer (such as paint or gel coat) may increase the risk of water penetration.

- Продолжительность воздействия воды:

- Short-term water exposure may only impact the composite’s surface, such as leaving water stains or damaging the protective layer.

- Длительное погружение в воду может привести к поглощению влаги матрицей смолы и ее расширению, что приведет к изменению размеров композита, снижению его эксплуатационных характеристик и даже разрушению структуры.

- Последующее лечение:

- Если композит намокнет, его следует быстро высушить, чтобы предотвратить негативные последствия длительного удержания воды.

- For already cured composites, if only the surface gets wet, its appearance and performance can usually be restored through cleaning and drying.

- If water has penetrated the composite interior, more complex repair measures may be required, such as locally replacing damaged parts or reinforcing the entire structure.

In summary, the impact of fiberglass resin getting wet depends on various factors, including the type of resin, the structure of the composite, the duration of water exposure, and subsequent treatment measures. In practical applications, appropriate protective and response measures should be taken based on specific situations to ensure the composite’s performance and service life.

В чем разница между ровингом и матовым стекловолокном?

Ниже приводится английский перевод предыдущего текста:

Различия между ровингом и матовым стекловолокном

1. Структурные различия

- Fiberglass Roving:

- Ровинг состоит из непрерывных пучков волокон, которые обычно не ткутся и не вяжутся, а сохраняют свою первоначальную форму, образуя пряди из полос волокон.

- Волокна ровинга обычно обладают высокой прочностью и жесткостью благодаря тому, что состоят из непрерывных волокон без точек прерывания.

- Стекловолоконный мат:

- Conversely, a mat is made from short-cut or continuous fibers that are randomly distributed, intertwined, and bonded (using powders or emulsion binders) into a sheet material.

- The fibers in the mat are arranged relatively chaotically, but this disorder gives the mat good flexibility and processability.

2. Области применения

- Fiberglass Roving:

- Roving is mainly used in applications requiring high strength and stiffness, such as manufacturing reinforced plastics (e.g., glass-fiber-reinforced plastic), pultrusion, and filament winding processes.

- It is also commonly used to produce high-performance composite materials and structural components, such as wind turbine blades, ships, and automotive parts.

- Стекловолоконный мат:

- Due to its flexibility and processability, the mat is widely used in hand lay-up, spray-up, and continuous lamination processes.

- It is also frequently used in manufacturing various FRP (fiber-reinforced plastic) products, such as pipes, storage tanks, and building panels because it provides uniform fiber distribution and good resin penetration.

3. Характеристики производительности

- Fiberglass Roving:

- Высокая прочность и жесткость, способность выдерживать значительные нагрузки на растяжение и изгиб.

- Хорошая направленность волокна, причем производительность вдоль направления волокна значительно выше, чем перпендикулярно ему.

- Стекловолоконный мат:

- Good flexibility, easy to handle, and shape.

- Uniform fiber distribution aids in uniform resin penetration and curing.

- Доступны различные варианты толщины и веса для удовлетворения конкретных потребностей.

4. Упаковка и транспортировка

- Fiberglass Roving:

- Typically packaged in rolls or bundles, convenient for transportation and storage.

- Необходимо соблюдать осторожность, чтобы предотвратить разрыв волокон и загрязнение.

- Стекловолоконный мат:

- Маты обычно упаковываются в листы или рулоны и могут требовать дополнительных защитных мер (например, обертывания пластиковой пленкой) для предотвращения сбрасывания волокон и впитывания влаги.

- To avoid deformation and damage, it should be kept dry and flat during transportation.

In summary, roving and mat fiberglass differ significantly in structure, application, performance, packaging, and transportation. The choice between them depends on specific application requirements and process demands.