Custom Glass Woven Fabric Manufacturer In China

- 16+ years of manufacturing experience

- CE, ISO, ROHS,SGS and other certifications

- Customize different gram weight width length sizes and colors

- Custom spun yarn, non twist roving, unidirectional, multi-axial, warp knitting and other reinforced fabrics

- OEM&ODM service, door to door service

années

Expérience en matière de fabrication

Projets

Nous avions terminé

Clients

Dans le monde entier

Satisfaction

Fiber Glass Fabric Manufacturer

High-End Automatic Jet Or High-Speed Rapier Loom Machinery

Our equipment has superior warp and weft weaving effect. Roots can be produced in different woven textures such as plain, twill or satin. The factory has 25 production lines, which are monitored throughout the process, greatly improving production efficiency and product quality.

- ISO 9001, CE , SGS and ASTM standards

- 25 automated weaving production lines to ensure on-time delivery

- Using high-quality raw materials: E-Glass, S-Glass, C-Glass, Basalt Fiber and Silica Fiber

- In-house Strictly Testing Lab for 6-step internal inspection

- Fire resistance test; UL 94 test, LOI test, HRR test, etc.

Professionnel

Technologie de fabrication avancée

Haute qualité

Certification CE, ASTM, SGS, ISO, BSCI de haute qualité

Efficacité des coûts

Prix direct d'usine

Sur mesure

Différentes tailles, couleurs et conceptions, OEM/ODM

Service

Excellent service à la clientèle

Hot Selling Fiberglass Fabric Series

We specialize in producing high-quality, versatile fiberglass fabrics with excellent physical properties including high strength, corrosion resistance, good insulation and strong heat resistance. These properties make it widely used in the construction industry, aerospace industry, and electronics industry. We are committed to providing customized fiberglass fabric solutions to meet the diverse needs of different industries and applications.

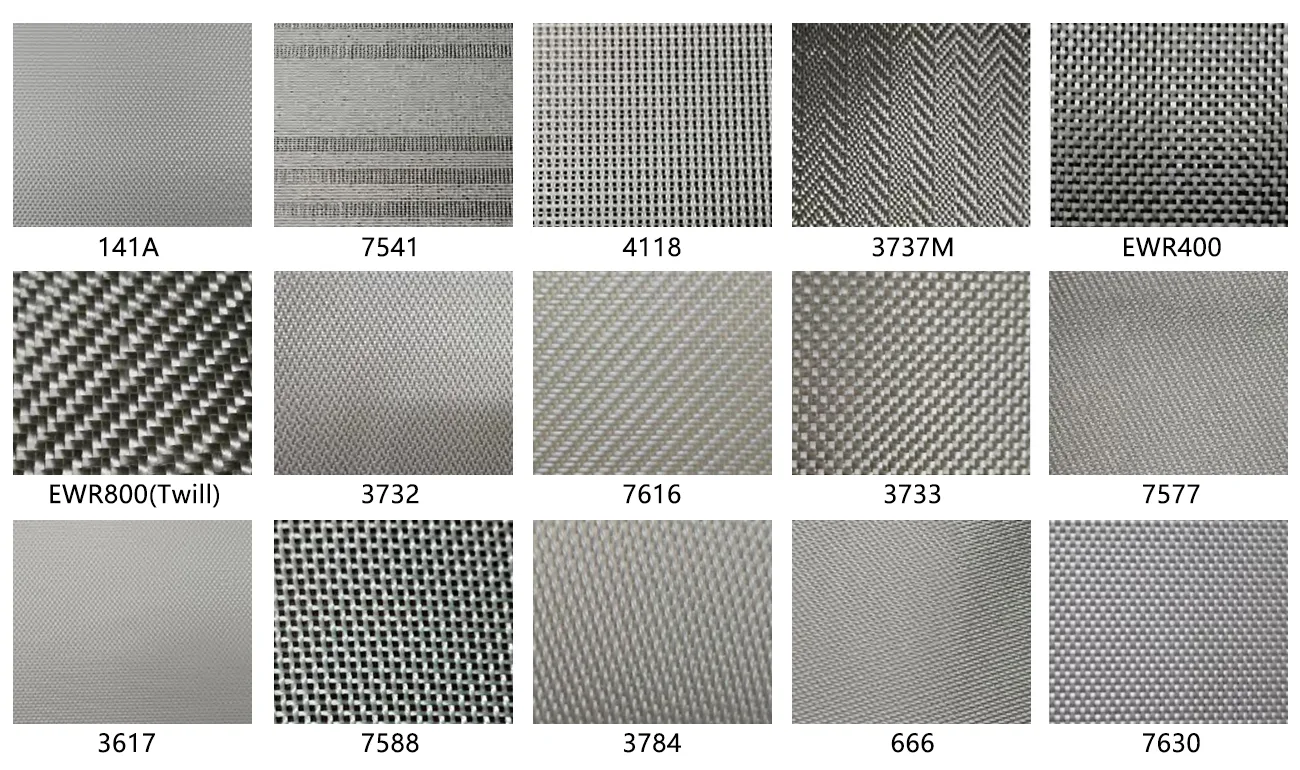

Fiberglass Fabric By Weaving

NQ glass fiber fabric is woven using three main techniques: plain, twill, and satin. Each method has its own unique characteristics, making it suitable for different products. These various weaves provide distinct advantages, allowing fiberglass fabric to meet a wide range of requirements in terms of strength, durability, and appearance.

Style | Weave | Warp yarn | Fill yarn | Thread Count (/in) | Weight(g/m2) | Thickness(mm) | Width(inch) | Tensile strength (kgf/2.5cm) | |

Distorsion | Trame | ||||||||

7628 | Plaine | EC G75 1/0 | EC G75 1/0 | 44x33 | 210 | 0.17 | 38-103.5 | ≥40 | ≥30 |

1080 | Plaine | EC D450 1/0 | EC D450 1/0 | 60x47 | 48 | 0.045 | 40-61 | ≥16 | ≥9 |

2116 | Plaine | EC E225 1/0 | EC E225 1/0 | 60x57 | 105 | 0.09 | 40-84 | ≥25 | ≥20 |

3732 | 4H Satin | EC G37 1/0 | EC G37 1/0 | 46x33 | 425 | 0.312 | 40-61 | ≥250 | ≥180 |

141A | Plaine | EC G75 1/2 | EC G75 1/2 | 30x20 | 280 | 0.227 | 40-96 | ≥140 | ≥130 |

7628HT | Twil | EC G75 1/0 | EC G75 1/0 | 44x38 | 220 | 0.166 | 40-103.5 | ≥120 | ≥100 |

7638 | Plaine | EC G75 1/0 | EC G37 1/0 | 44x25 | 253 | 0.265 | 40-96 | ≥140 | ≥120 |

7630 | Plaine | EC G67 1/0 | EC G67 1/0 | 44x31 | 225 | 0.22 | 40-101 | ≥130 | ≥100 |

5430 | Plaine | EC G75 1/0 | EC G75 1/0 | 36x30 | 180 | 0.153 | 50-100 | ≥120 | ≥100 |

G/FM153 | Plaine | EC D450 1/0 | EC G150 1/0 | 120x66 | 145 | 0.135 | 40-50 | ≥40 | ≥60 |

3617 | Plaine | EC G150 1/0 | EC G75 1/0 | 40x17 | 105 | 0.13 | 50-74.5 | ≥90 | ≥70 |

1815 | Plaine | EC G75 1/0 | EC G75 1/0 | 36x30 | 182 | 0.158 | 40-50 | ≥80 | ≥70 |

7581 | 8H Satin | EC G75 1/0 | EC G75 1/0 | 57x55 | 305 | 0.2 | 43-53 | ≥60 | ≥50 |

7781 | 8H Satin | EC DE75 1/0 | EC DE75 1/0 | 56x55 | 300 | 0.215 | 36-50 | ≥200 | ≥160 |

7667 | Plaine | EC G67 1/0 | EC G67 1/0 | 44x36 | 235 | 0.235 | 40-53 | ≥40 | ≥30 |

2321 | Plaine | EC G37 1/0 | EC G37 1/0 | 33x21 | 295 | 0.235 | 40-101.5 | ≥150 | ≥100 |

3784 | 8H Satin | EC G37 1/2 | EC G37 1/2 | 46x35 | 875 | 0.67 | 39-60 | ≥270 | ≥220 |

666 | 8H Satin | EC G75 1/3 | EC G75 1/3 | 40x38 | 660 | 0.43 | 38-61 | ≥220 | ≥200 |

3602 | Sergé | ECT DE75 1/0 | ET6-145R/NT | 54x33 | 339 | 0.28 | 38-65 | ≥160 | ≥140 |

3737M | Sergé | EC G37 1/0 | EC G37 1/0 YI | 31x26 | 305 | 0.21 | 40-61 | ≥180 | ≥160 |

3733 | Plaine | EC G37 1/0 | EC G37 1/0 | 18.7x18.7 | 200 | 0.19 | 31-132 | ≥100 | ≥100 |

7577 | Sergé | ECT DE75 1/2 | ET6-285R | 46x40 | 745 | 0.68 | 40-72 | ≥180 | ≥200 |

5125 | Plaine | EC G150 1/0 | ET6-68S/FT | 51x25 | 140 | 0.17 | 50-124 | ≥80 | ≥60 |

7588 | Plaine | EC G75 1/4 | EC G75 1/4 | 14.2x13.6 | 305 | 0.3 | 50-125 | ≥100 | ≥90 |

1652 | Plaine | EC G150 1/0 | EC G150 1/0 | 52x52 | 141 | 0.12 | 50 | ≥70 | ≥70 |

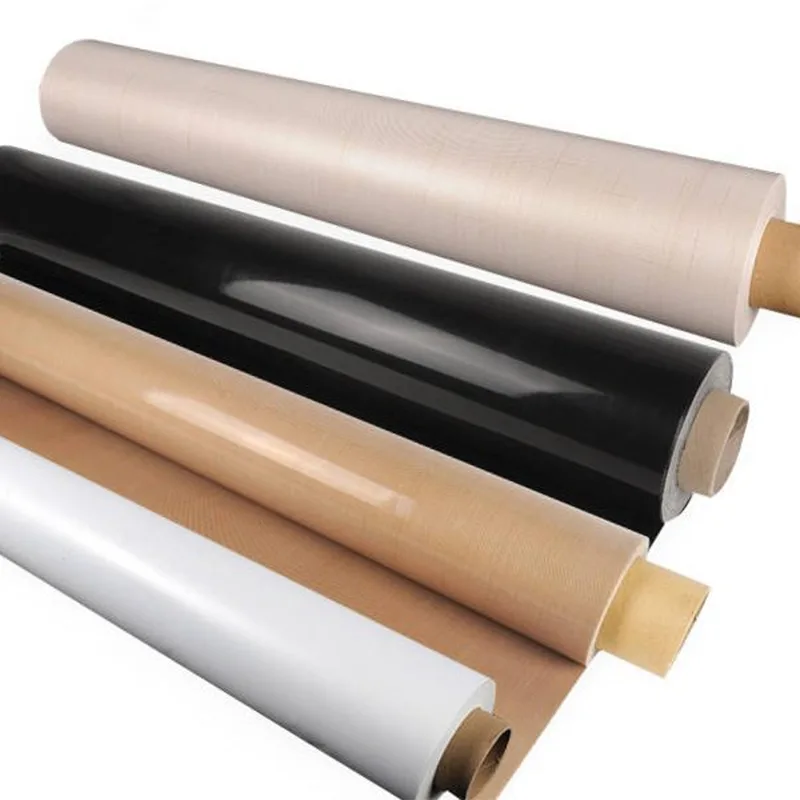

Tissu de fibre de verre enduit de silicone

En général, l'artisanat spécial est fait de verre, qui est fabriqué à partir de matériaux composites. Résistance aux températures élevées, résistance à la corrosion chimique, étanchéité, résistance au vieillissement et intégrité. Aviation, aéronautique, traitement chimique, électronique et autres activités.

Tissu de fibre de verre aluminisé

En général, la structure physique de la feuille de verre est obtenue grâce à des techniques artisanales spéciales. L'équipement présente une isolation thermique exceptionnelle, une résistance au feu, une résistance à la pourriture, ainsi qu'un poids et une résistance élevés. Une variété de matériaux durables et esthétiques pour la construction aéronautique, l'aviation et d'autres opérations.

Tissu de fibre de verre enduit de PU

Le tissu de fibre de verre enduit de PU est un matériau composite de haute performance créé par l'application uniforme de polyuréthane sur la fibre de verre grâce à un processus spécialisé. Il présente une excellente résistance à la température, au feu, à l'usure et à l'eau, ce qui en fait un matériau idéal pour la construction, l'aérospatiale, le transport et d'autres industries.

Tissu de fibre de verre enduit de PVC

Combine la résistance du tissu de fibre de verre général avec les performances d'imperméabilité du PVC, et dispose de composants techniques spéciaux pour l'imperméabilisation, l'ignifugation, la résistance à la pourriture, la résistance au vieillissement et d'autres matériaux composites de haute performance, pour une utilisation dans la construction, le transport, la protection solaire, etc.

Tissu en fibre de verre enduit d'acrylique

Le tissu de fibre de verre enduit d'acrylique allie une grande solidité à une excellente résistance à la corrosion et aux intempéries. Ce matériau polyvalent est largement utilisé dans la construction, les transports et diverses autres industries.

Ceramic Fiber Fabric

Ceramic fiber fabric is a high-performance, lightweight refractory material made from high-quality ceramic fibers. After undergoing a specialized treatment process, it exhibits excellent high-temperature resistance, heat insulation, and corrosion resistance. This versatile fabric is widely used in industries such as metallurgy and chemical processing.

Fiberglass Prepreg

Fiberglass prepreg is mainly composed of a resin matrix and reinforced fiber (glass fiber). The resin matrix is usually made of epoxy resin, styrene resin, etc., and glass fiber provides excellent mechanical properties for Prepreg with its high strength, low density and good corrosion resistance.

PTFE Coated Fiberglass

The combination of the strength of fiberglass and the excellent properties of PTFE provides high temperature resistance, corrosion resistance, low friction, and electrical insulation. It is widely used in industries such as food processing, chemicals, and electronics.

Hypalon Fabric Coated Fiberglass

Combines fiberglass with Hypalon, offering excellent weather, chemical, and UV resistance. It’s durable, flexible, and widely used in industrial fabrics and chemical-resistant applications.

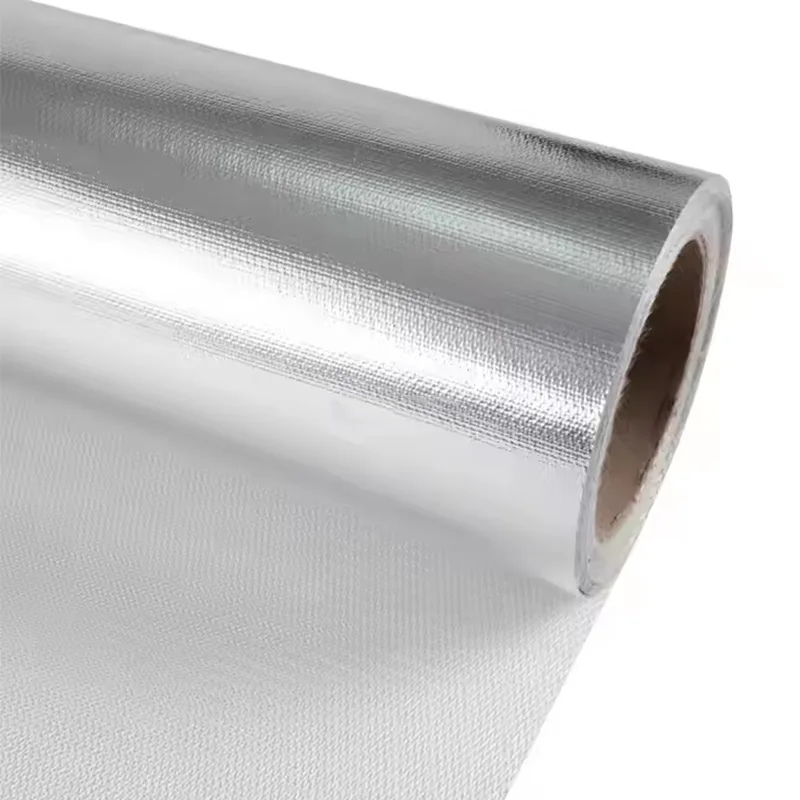

Aluminum foil composite glass fiber cloth

It is made of glass fiber as base cloth and composite aluminum foil. The composite aluminum foil has the characteristics of smooth surface, high reflective refractive index, high strength, impermeable, airtight, and strong weather resistance.

Silica fabric

High/medium silicon cloth has good chemical stability, high temperature resistance and insulation. It is widely used for protection in extremely high temperature environments.

Boost Your Business With Custom Fiberglass Fabric

NQ custom fiberglass fabrics allow customers to choose the gram weigth texture, size, color and finish that best suits their needs. We are committed to meeting your specific requirements and all meet strict quality control standards. With our advanced manufacturing process, your products will stand out.

Customized weaving method

We support various fabric structures, including plain, twill, and satin, as well as customization for different braiding options, such as single strands and twisted plies. You can customize according to your project needs to get the best project effect.

Personnalisation de l'emballage

We use various packaging methods for different sizes of fiberglass fabric, including polyethylene bags, cartons, cardboard boxes, wooden crates, and roll packaging. The choice of packaging depends on the type, specifications, and intended use of the fabric. You can also request specific packaging to ensure your product is well protected.

Explore our selection of custom solutions to find the right one for your needs

Fiber Glass Fabric Specifications

Lieu d'origine | China |

Nom de la marque | NQ |

Numéro de modèle | Glass fiber twisted fabrc,Glass fiber woven roving,Glass fiber unidirectional fabric,Glass fiber axialfabric,Glass fiber multiaxialfabric |

Poids | 200g/m2,430g,100g,260g/m2,600g,Different models have different weights |

Surface Treatment | Silicon Coated |

Largeur | 0.18mm,0.1mm,0.24mm,100-5200mm,custom |

Taille des mailles | 13x16mm(7628),13×16,Different models have different specifications |

Weave Type | Plain, twill, satin, etc |

Yarn Type | E-glass,C-glass,etc. |

Alkali Content | Alkali Free |

Température à l'arrêt | 550C |

Couleur | White, grey, black, custom |

Quality Control | 1. Inspection at Site. |

Matériau | E Glass/ Fiber Yarn |

Good Features | Insulation, heat resistance, corrosion resistance, high strength and good mechanical properties |

Épaisseur | 0.03-0.90±0.10mm,It varies from model to model |

temperature | 550℃ |

Roll Length | 1-50m,Cusomized |

Utilisation | Aerospace, automobile manufacturing, construction, electronics, sports equipment, shipbuilding and new energy and other industries |

Delivery time | 25-30 days after sample confirmed |

Produce Name | Tissu en fibre de verre |

Matériau | 100% Fiberglass |

Glass type | E/C-GLASS |

Couleur | White,customizable |

Unit weight | 225gsm/300gsm/450gsm/600gsm,customizable |

Largeur | 1040 mm/1250mm/1270mm/2850mm,customizable |

NQ Fiberglass Fabric Production Process

1. Matières premières

We source our material from the world’s largest producer, Monolith Group. 20% stronger than standard fiberglass yarn.

2. Processus de torsion

The automatic twisting machine is combined with tension and yarn guide devices to ensure uniform tension during the twisting process.

3. le processus de tissage

The fiberglass yarn is woven on a high-speed rapier loom and uses tension magnetic separators to alleviate distortion, resulting in a strong and flexible cloth.

4. Processus d'enduction

Pretreatment is performed to apply one or more intermediate layers on the primer. Common types include acrylic, polyurethane, and fluorocarbon paints.

5. Drying And Curing

Different curing methods are carried out according to different materials to ensure that the resin or paint fully hardens and forms a durable protective layer.

6. Processus de coupe

Mechanical cutting employs automatic or laser cutting machines that follow a preset program to ensure fast and accurate cuts, making it ideal for mass production or complex shapes.

7. contrôle de la qualité

8. Emballage

We provide various packaging methods such as folding, folding, etc., and the quality of the products we maintain is free of charge during the course of delivery.

SF

Entrepôt et usine

Recettes annuelles totales

Travailleur qualifié

Partner With NQ To Elevate Your Project To Success

Premium quality:With 25 production lines and cutting-edge fiberglass textile technology, we ensure top-quality fiberglass materials through strict quality control.

Competitive price:By choosing our custom fiberglass fabric, you’ll enjoy top-quality products, competitive pricing, and timely delivery—helping you save costs and avoid delays.

Fully Customize:As your trusted fiberglass fabric manufacturer, we provide tailor-made customization services and packaging solutions for a variety of fiberglass products, including weight, texture length, etc.

Certificat

NQ Fiberglass Fabric: Unmatched Quality and Performance

Our expertise in fiberglass manufacturing positions us as one of the most trusted fiberglass fabric and cloth manufacturers in China. With our own fiberglass factory, we produce a wide variety of fiberglass fabrics and other products for the fiberglass industry, enabling us to accept wholesale orders from customers looking to reduce costs. Our fiberglass fabric offers the following benefits:

Excellent Insulation Properties

With fiberglass fabric, you get superior electrical insulation, ensuring safe and stable operation of your equipment.

Excellent Heat Resistance

Choose fiberglass fabric for reliable performance in high temperatures, ensuring durability and resistance to deformation in industrial applications.

Excellent Corrosion Resistance

Excellent corrosion resistance, protecting your equipment from acids, alkalis, and chemicals to extend its lifespan.

Non-flammable

Fiberglass fabric is made from inorganic materials, making it non-flammable with a melting point of up to 1300°C (2372°F). It is not only non-flammable but also remains stable at high temperatures and does not release toxic gases.

Light Weight And High Strength

Fiberglass fabric is lighter and stronger than metal, which supports efficient design, energy saving and easy transportation.

Good Processability And Adaptability

Fiberglass fabric can be easily customized in shape and size, and surface treatment can enhance performance and appearance.

What Purchaser Say About Us

“Working with NQ fiberglass fabric has always been a smooth experience. The quality of their products is consistently stable, ensuring that each batch meets our high standards, which significantly reduces our quality control costs. Additionally, their delivery times are always reliable, providing strong support for our production schedule. Overall, NQ is undoubtedly one of our most trusted partners.”

Daniel Parker

Entrepreneur

“My first experience using NQ fiberglass fabric was highly satisfying. From the initial sample testing to subsequent bulk orders, the entire process was efficient and professional. I especially appreciated their customer service team, who were very patient and offered valuable advice and assistance to our new customers with specific product requirements. I look forward to more collaboration opportunities in the future.”

James Rodriguez

Entrepreneur

“Since choosing NQ fiberglass fabric as our supplier, I have clearly noticed an increase in cost-effectiveness. Their competitive pricing and flexible batch customization services, combined with a commitment to quality, have helped us effectively reduce inventory pressure and production costs. The NQ team is a valuable partner that responds quickly to market needs and consistently provides the best cost optimization solutions at critical moments.”

Mark Wilson

Entrepreneur

Application Of Glass Fiber Fabric

Industrie de la construction

Direct roving for pultrusion is compatible with unsaturated polyester, vinyl ester, epoxy, and phenolic resins. It is widely used in various fields, including construction and the telecommunications industry.

Type of fiber:E/ECR-GLASS

Linear density( tex):300-9600

Compatible resin:UP,VE

Electronic And Electrical Industry

Direct roving for LFT is designed for reinforcing PP and PA resins and is widely used in industries such as automotive, construction, packaging, military, and electrical markets.

Type of fiber:E-GLASS

Linear density ( tex ):300-2400

Compatible resin:PP, PA

Industrie des transports

The roving is compatible with polyester, vinyl ester, and epoxy resin systems. It is specifically designed for the FRP filament winding process, providing rapid wet-out and thorough saturation with low resin consumption.

Type of fiber:E/ECR-GLASS

Linear density( tex ):300-9600

Compatible resin:UP,VE,PF

New Energy Industry

Direct roving for weaving is compatible with polyester, vinyl ester, phenolic, and epoxy resins. It is widely used in the production of fiberglass warp knitting fabric, wind turbine blades, and in the boat industry, among other applications.

Type of fiber:E/ECR-GLASS

Linear density( tex ):300-4800

Compatible resin:UP,VE,PF

ERP Product

The roving is designed for spraying process. it is treated with silane sizing which is compatible with unsaturated polyester. The typically applications include automotive parts, FRP boat hulls, sanitary products, FRP storage tanks, pipes, cooling towers and so on.

Type of fiber:E-GLASS

Linear density( tex ):2400/4800

Compatible resin:UP,VE

Structural Product

The roving is designed to contribute to Class “A” surface in different applications. lt is suitable to be used in the automotive parts such as truck body panels, grill opening panels where smooth surface is needed, it can also be used for structural molded applications.it also contributes good laminate mechanical properties.

Type of fiber:E/ECR-GLASS

Linear density ( tex ):2400/4800

Chopping Roving For Headliner

It is specially designed for hot press molding automotive headliner manufacturing. lt has good fiber distribution which contributes to a good finished headliner surface. lt has excellent molding property so the finished headliner will not have any wrinkles.

Type of fiber:E/ECR-GLASS

Linear density( tex ):2400/4800

Compatibie resin:UP,VE,PU

Assembled Roving For Pultrusion

The roving is compatible with polyester, vinyi ester, and epoxy resin systems. lt is

designed for use in the end products which require high mechanical properties. it

can be used for FRP grid, FRP windows and doors, FRP tent supporting pole.

Type of fiber:E/ECR-GLASS

Linear density( tex ):2400/4800

Filament diameter:13-14

Compatible resin:UP,VE

Panel Roving

It is designed to be used in continuous FRP transparent panel production. The

finished product offers light weight, high strength, high impact resistance and

excellent transparency.

Type of fiber:E/ECR-GLASS

Linear density( tex ):2400-4800

Compatible resin:UP,VE

Assembled Roving For Chopping

The roving are compatible with polyester, vinyl ester and epoxy resins, principally

used to produce CSM and stitch combo mats.

Type of fiber:E-GLASS

Linear density(tex) :2400

Fiament diameter:12-13

Compatibie resin:UP, VE

Size content ( %):0.5±0.15

Assembled Roving For GMT

Assembled roving for GMT is designed for reinforcing modified PP.And it is a

structural material,which is widely used in automotive,construction,packaging,

electrical equipments industry and so on.

Type of fiber:E/ECR-GLASS

Linear density( tex):2400

Compatible resin:PP

Combotex Roving

COMBOTEX ROVING(PP+GIBERGLASS) is a kind of high performance prepreg which is made of glass fiber coated PP resin, which can be directly used to form PP resin composite, wilhout the need to add extra resin.

The use of the product includes aerospace, automotive industry, construction, sports equipment, new energy and other aspects.

Type of fiber:E/ECR-GLASS

Resin:Polypropylene resin

Fiberglass Content:60%

Linear density(tex):1870

Frequently Asked Questions

Below you can find some frequently asked questions about shipment and MOQ. If you have any further questions, please feel free to contact us.

Quel est votre MOQ ?

Notre MOQ est généralement de 1 conteneur de 20 pieds, mais nous acceptons des quantités inférieures pour vos commandes d'essai. N'hésitez pas à nous faire part de votre projet de

nous vous proposerons un prix correspondant à votre quantité. Nous espérons que vous augmenterez le nombre de vos commandes après avoir vérifié nos produits.

la qualité des produits et connaître nos services.

Quel est le port d'embarquement ?

Les marchandises sont expédiées via le port de Shanghai.

Combien de couleurs sont disponibles ?

Nous pouvons réaliser des couleurs personnalisées lorsque nous atteignons notre QMOS.

Nos couleurs habituelles sont le blanc, le jaune, le vert, le bleu, l'orange, le rouge, etc.

De quel format de fichier ai-je besoin si je veux créer mon propre dessin ?

Pour la conception d'étiquettes d'impression, nous avons besoin d'un fichier AI ou PDF pour créer la plaque d'impression.

Quel est votre délai de livraison ?

Le délai de livraison est d'environ 20 à 30 jours après réception de l'acompte.

Quelle est la durée de l'échantillonnage ?

En général, il faut compter 7 à 10 jours pour la fabrication des échantillons.

Quel est le mode d'expédition disponible ?

Par voie maritime jusqu'au port désigné.

Quelle voie de paiement est envisageable ?

1. L/C irrévocable, espèces, PayPal, carte de crédit et transferts de fonds T/T.

2.30% dépôt T/T à l'avance, 70% solde avant expédition après présentation de la cargaison prête.

3.L/C (LC irrévocable à vue)

Si vous avez besoin de dimensions personnalisées (poids en grammes, taille des mailles, etc.) ou d'un logo personnalisé, n'hésitez pas à nous contacter !

Fiberglass Fabric FAQ

What is glass fiber cloth?

Glass fiber cloth, also known as fiberglass fabric, is a textile made from woven strands of glass fibers. It possesses excellent properties such as high insulation, heat resistance, corrosion resistance, and mechanical strength. These attributes make it widely used in various industries, including automotive, aerospace, construction, and electrical applications.

Key Characteristics:

High Insulation: Provides excellent electrical insulation, making it ideal for electrical applications.

Heat Resistance: Capable of withstanding temperatures ranging from -196°C to 300°C, offering good weather resistance.

Corrosion Resistance: Resistant to strong acids, strong alkalis, aqua regia, and various organic solvents.

High Strength: Exhibits good mechanical properties with high tensile strength.

Low Friction Coefficient: Serves as an excellent choice for self-lubricating applications due to its low friction coefficient.

Transparency: Offers a light transmittance rate of 6–13%.

High Insulation Performance: Provides high insulation, UV resistance, and antistatic properties.

Common Applications:

Electrical Insulation: Used in electrical circuit boards and other electrical insulation materials.

Construction Materials: Employed as reinforcement in building materials.

Automotive and Aerospace: Utilized in vehicle and aircraft components for its strength and heat resistance.

Industrial Insulation: Applied in high-temperature insulation and fire-resistant products.

Chemical Filtration: Used as a filtration medium for chemicals.

Textile Industry: Serves as a base material for high-elasticity transmission belts.

Wall Coverings: Used in wall coverings due to its durability and resistance to wear.

It’s important to note that while glass fiber cloth offers numerous benefits, it can be brittle and may cause skin irritation during handling. Therefore, appropriate protective measures, such as wearing gloves and masks, are recommended during its use.

What material is fiberglass?

Fiberglass, also known as glass fiber, is a versatile material composed of fine strands of glass. These strands are woven into a fabric or combined with resins to form composite materials. The primary components of fiberglass include silica sand, limestone, and soda ash, which are melted together at high temperatures to produce glass fibers.

Key Characteristics of Fiberglass:

High Insulation: Provides excellent electrical insulation, making it ideal for electrical applications.

Heat Resistance: Capable of withstanding temperatures ranging from -196°C to 300°C, offering good weather resistance.

Corrosion Resistance: Resistant to strong acids, strong alkalis, aqua regia, and various organic solvents.

High Strength: Exhibits good mechanical properties with high tensile strength.

Low Friction Coefficient: Serves as an excellent choice for self-lubricating applications due to its low friction coefficient.

Transparency: Offers a light transmittance rate of 6–13%.

High Insulation Performance: Provides high insulation, UV resistance, and antistatic properties.

These properties make fiberglass a popular choice in various industries, including construction, automotive, aerospace, and electrical applications.

Is fiberglass cloth waterproof?

Fiberglass cloth, composed of woven glass fibers, is inherently water-resistant due to its composition. However, to achieve complete waterproofing, it must be combined with a suitable resin. When used with Bondo® Fiberglass Resin, repairs become 100% waterproof, making the products ideal for applications such as tubs, showers, sinks, pools, hot tubs, and boat repairs.

Bondo® Fiberglass Resin is a high-strength polyester resin designed for repairing chips, cracks, and rebuilding surfaces on fiberglass, metal, wood, and masonry. Its two-part formula creates an extremely strong chemical bond to surfaces, ensuring durability and waterproofing. This resin is compatible with Bondo® Fiberglass Cloth or Mat, enhancing the strength and longevity of repairs.

In summary, while fiberglass cloth alone offers water resistance, combining it with Bondo® Fiberglass Resin ensures a fully waterproof solution suitable for various repair projects.

What are the three types of fiberglass cloth?

Fiberglass cloth is a versatile material used in various applications, and it comes in several types, each suited to specific needs. While there isn’t a universally agreed-upon classification into exactly three types, fiberglass cloths are commonly categorized based on their weave patterns, weight, and resin compatibility.

1. Woven Fiberglass Cloth:

This type is made by interlacing glass fibers in specific patterns, such as plain, twill, or satin weaves. The choice of weave affects the fabric’s flexibility, strength, and suitability for different applications.

2. Chopped Strand Mat (CSM):

CSM consists of randomly oriented glass fibers bonded together with a resin. It’s known for its ease of use and is commonly used in applications where a uniform thickness is required, such as boat hulls and automotive parts.

3. Biaxial and Triaxial Fabrics:

These fabrics have fibers oriented at specific angles (typically 0/90 degrees for biaxial and 0/90/45 degrees for triaxial), providing enhanced strength in particular directions. They’re often used in applications requiring high strength and stiffness, such as in aerospace and automotive industries.

It’s important to note that fiberglass cloths can also be categorized based on their weight (measured in ounces per square yard), which influences their strength and suitability for different applications. Lighter cloths are ideal for surface layers and adding a sleek finish, while heavier cloths are used for building thickness and strength.

Understanding the specific requirements of your project will help in selecting the appropriate type of fiberglass cloth.

What is fiberglass fabric used for?

Fiberglass fabric is a textile made from woven glass fibers, offering lightweight, high strength, heat resistance, corrosion resistance, and other excellent properties.

Key Applications:

Construction and Building: Used in the manufacturing of reinforced plastic (RP) products such as roofs, exterior walls, and structural components, providing a lighter and stronger alternative material.

Automotive Industry: Used in the production of body parts, interior components, and custom accessories, offering strength and durability.

Shipbuilding: Used in hulls, storage tanks, cooling towers, etc., providing corrosion resistance and structural strength.

Sports Equipment: Used in the production of surfboards, skis, tennis rackets, and more, offering lightweight and high strength.

Everyday Items: Used in the manufacturing of doors, swimming pools, surfboards, sporting equipment, automobile bumpers, and more.

The versatility of fiberglass fabric makes it widely used across various industries, meeting the demand for high-performance materials.

What is the difference between fiberglass cloth and fiberglass mat?

Fiberglass cloth and fiberglass mat are both forms of fiberglass material, but they differ in their structure, properties, and applications. Here are the key differences between the two:

1. Structure

Tissu de fibre de verre: Fiberglass cloth is a woven material made from glass fibers that are intertwined in a similar fashion to traditional fabrics. The fibers are arranged in a crisscross pattern to form a strong, flexible sheet.

Tapis en fibre de verre: Fiberglass mat, on the other hand, is a non-woven material made from glass fibers that are randomly oriented and bonded together using a binder material. This results in a less structured, more flexible, and conformable material.

2. Properties

Strength and Durability: Both fiberglass cloth and mat are known for their strength and durability. However, fiberglass cloth tends to be stronger and more rigid due to its woven structure, making it better suited for applications requiring high structural integrity.

Conformability: As mentioned in the given statement, fiberglass mat is easier to conform to tight corners and curves due to its non-woven, flexible nature. This makes it ideal for applications where a tight fit is required, such as insulation or soundproofing in complex shapes.

Surface Finish: Fiberglass cloth has a smoother surface finish compared to fiberglass mat, which can have a more textured appearance due to the random orientation of its fibers.

3. Applications

Tissu de fibre de verre: Fiberglass cloth is widely used in composites manufacturing, where it is combined with resins to create strong, lightweight structures. It is also used in electrical insulation, building reinforcement, and as a base material for various industrial applications.

Tapis en fibre de verre: Fiberglass mat is commonly used in insulation and soundproofing applications due to its conformability and ability to fill gaps and voids. It is also used in the production of fiberglass core materials for composites, where it provides additional strength and stiffness.

Résumé

In summary, the main differences between fiberglass cloth and fiberglass mat lie in their structure, properties, and applications. Fiberglass cloth is a woven material with high strength and rigidity, making it suitable for structural applications. Fiberglass mat, on the other hand, is a non-woven material with excellent conformability, making it ideal for insulation and soundproofing in complex shapes.

Why use fiberglass cloth?

Fiberglass cloth is a versatile material renowned for its lightweight nature, high strength, and exceptional moldability into complex shapes. These attributes make it an ideal choice across various industries.

Key Advantages of Fiberglass Cloth:

Lightweight and Strong: Fiberglass cloth offers a high strength-to-weight ratio, making it both lightweight and strong. This combination is particularly beneficial in applications where reducing weight is crucial, such as in aerospace and automotive industries.

Moldability: One of the most prized properties of fiberglass is its ability to be molded into various complicated shapes. This flexibility allows for the creation of intricate designs and structures, expanding its range of applications.

Corrosion Resistance: Fiberglass cloth exhibits excellent resistance to corrosion, making it suitable for environments exposed to chemicals and moisture. This property enhances the durability and longevity of products made from fiberglass cloth.

Thermal Insulation: Fiberglass cloth provides excellent insulation properties, making it ideal for electrical and thermal insulation applications. Its tightly woven fibers create a barrier that effectively prevents heat transfer, suitable for use in environments where temperature control is critical.

Electrical Insulation: Fiberglass cloth is alkali-free and used for electrical insulation, offering excellent electrical insulation properties.

Sound Insulation: The material is an efficient solution for sound insulation and the creation of acoustics.

These properties make fiberglass cloth a preferred material in various applications, including construction, automotive manufacturing, shipbuilding, sports equipment, and everyday items.

Is fibreglass fabric safe?

Fiberglass fabric is generally safe to use in a wide range of applications due to its excellent properties like high strength, light weight, and moldability. However, as with any material, it is important to handle fiberglass fabric properly to ensure safety.

When working with fiberglass fabric, we recommend taking a few simple precautions:

Wear Personal Protective Equipment (PPE): Use gloves, safety glasses, and a dust mask or respirator when handling fiberglass, especially during cutting, sanding, or grinding. This helps prevent irritation to the skin, eyes, and respiratory system.

Work in a Well-Ventilated Area: Ensuring good airflow will help reduce the risk of inhaling fiberglass particles that may be released during the fabrication process.

Minimize Dust Exposure: If possible, dampen the fabric slightly before handling to reduce the amount of dust that could be released into the air.

Proper Disposal: After using fiberglass fabric, dispose of any scraps and dust properly to avoid contact with skin or inhalation.

By following these simple safety measures, you can enjoy the benefits of fiberglass fabric while ensuring a safe working environment.

How strong is fiberglass fabric?

Fiberglass fabric is known for its remarkable strength-to-weight ratio. Here are the key points to understand its strength:

Specific Strength of Fiberglass Fabric:

- The specific strength of fiberglass fabric is approximately 1,307 kN·m/kg. This is a measure of the material’s strength relative to its weight. It indicates that fiberglass is strong for its lightness, making it ideal for various structural applications. (source).

Comparison with Other Materials:

- Stainless Steel: The specific strength of stainless steel is around 63.1 kN·m/kg. This is much lower than fiberglass.

- Titanium: Titanium has a specific strength of approximately 260 kN·m/kg.

- Fiberglass vs. Stainless Steel: Fiberglass is about 20.7 times stronger (in terms of specific strength) than stainless steel.

- Fiberglass vs. Titanium: Fiberglass is approximately 5 times stronger than titanium.

Implications:

- The high specific strength of fiberglass fabric means it provides excellent strength while remaining lightweight.

- This makes it an ideal material for applications in industries like aerospace, automotive, construction, and sports equipment, where both strength and weight are critical factors.

In summary, fiberglass fabric offers exceptional strength relative to its weight, making it one of the most efficient materials for lightweight yet strong constructions.

Glass fiber fabrication process and thickness.

Glass fiber fabric is a versatile material widely used in various industries due to its excellent strength-to-weight ratio, heat resistance, and electrical insulating properties. The fabrication process and thickness of glass fiber fabric are crucial factors that influence its performance and suitability for specific applications.

Fabrication Process:

Batching: The process begins with the selection and blending of raw materials, primarily silica sand, along with other components such as alumina, calcium oxide, and boron oxide. These materials are carefully proportioned to achieve the desired glass composition.

Melting: The blended raw materials are melted at high temperatures, typically around 1,400°C to 1,500°C, in a furnace. This results in a homogeneous molten glass.

Fiberization: The molten glass is then drawn into fibers through various methods, such as blowing, drawing, or spinning. The choice of method depends on the desired fiber diameter and application.

Sizing: The glass fibers are coated with a sizing agent to enhance their handling properties and improve adhesion to resins in composite materials.

Weaving: The sized fibers are woven into fabrics using traditional weaving techniques, resulting in various fabric types such as plain weave, twill, or satin weave, depending on the intended application.

Thickness of Glass Fiber Fabric:

Glass fiber fabrics are available in a wide range of thicknesses to meet diverse application requirements:

Standard Thickness Range: Typically, glass fabrics are available in thicknesses ranging from approximately 0.001 inches (0.025 mm) to 0.060 inches (1.524 mm).

Customization: Manufacturers can produce fabrics with specific thicknesses tailored to particular needs, allowing for flexibility in design and application.

Weight Variations: The weight of glass fabrics varies from 20 grams per square meter (gsm) to over 1,000 gsm, influencing the fabric’s strength, flexibility, and suitability for different applications.

The selection of fabric thickness and weight is determined by factors such as the mechanical requirements of the application, desired flexibility, and compatibility with resin systems used in composite manufacturing.

Understanding the fabrication process and the range of available fabric thicknesses is essential for selecting the appropriate glass fiber fabric to ensure optimal performance in its intended application.

Can clothes be made out of fiberglass?

Yes, clothes can technically be made out of fiberglass.

Here is a detailed breakdown of whether clothes can be made out of fiberglass:

What is Fiberglass?

- Fiberglass is a synthetic material commonly used in many products, including textiles. It is made from molten glass that is spun into fibers through centrifugal force. It is also known as glass wool or rock wool. (source)

Use in Clothing:

- Fiberglass is not typically used in everyday clothing due to its stiffness and the potential for skin irritation. It is not as comfortable as traditional fabrics used for daily wear.

- However, fiberglass fabric is used in specialized protective clothing for certain industrial applications where durability and resistance to heat are required. These garments are used in environments such as welding, firefighting, and chemical processing.

Why is Fiberglass Used in Protective Clothing?

- Fiberglass clothing is designed to provide protection against high temperatures, flames, and hazardous chemicals.

- These garments are often flame-resistant and capable of withstanding extreme conditions. They are specifically engineered to safeguard workers in dangerous work environments.

Can you wash fiberglass fabric?

Yes, fiberglass fabric can be washed, but it requires special care and handling.

Fiberglass fabric is widely used in industrial applications due to its excellent strength and heat resistance. Here are the recommended methods for cleaning fiberglass fabric:

Hand Wash:

- Use a mild detergent and lukewarm water to gently hand-wash fiberglass fabric.

- Avoid using bleach or harsh chemicals, as these can damage the fabric.

- Thoroughly rinse to ensure all detergent is removed.

- Gently squeeze out excess water by hand, but avoid wringing the fabric.

Wear Protective Gear:

- Wear rubber gloves while cleaning to protect your skin from fiberglass fibers.

- Consider wearing a mask to avoid inhaling fine fiberglass particles during the cleaning process.

Drying:

- Lay the cleaned fiberglass fabric flat to air dry, avoiding direct sunlight.

- Do not iron fiberglass fabric, as this could damage the material.

Note that fiberglass fabric may release fine particles during washing, which can cause skin irritation or respiratory discomfort. Therefore, it’s important to take proper safety precautions. Additionally, regularly inspect stored fiberglass fabric to ensure it is not damaged or damp, to maintain its performance and prolong its lifespan.