Manufacture Of Fiberglasss Mat Supplier In China

- Más de 16 años de experiencia en fabricación industrial

- ISO, CE, BSCI, RoHS, SGS certification

- Professional oem and odm services, one-stop solution.

- Color customization: white, grey, black, etc

- Size customization: wide 50-3800mm, thickness 0.10-0.70mm, etc

años

Experiencia en fabricación

Proyectos

Habíamos terminado

Clientes

En todo el mundo

Satisfacción

Fiberglass Mat Manufacturer

High-performance Automated Roller Press Machine

Our roller press machine provides uniform density compaction, and the rolling process also improves the surface quality of the fiberglass mat, making it smoother and more consistent, ensuring material strength and stability. It is also capable of handling a variety of different materials.

- ISO 9001, ISO 14001, CE, SGS, ASTM, OHSAS, GOST and other standard certifications.

- 35 automated production lines.

- Good plasticity and fast resin penetration.

- High-quality raw materials: E glass, S glass, C glass and AR glass, etc.

- Strict tests: tensile strength, high temperature resistance, corrosion resistance, etc.

Profesional

Tecnología de fabricación avanzada

Alta calidad

Certificación de alta calidad CE, ASTM, SGS, ISO, BSCI

Rentable

Precio directo de fábrica

Personalizado

Diferentes tamaños, colores, diseños, OEM/ODM

Servicio

Excelente servicio al cliente

Fiberglass Mat Hot Sale Series

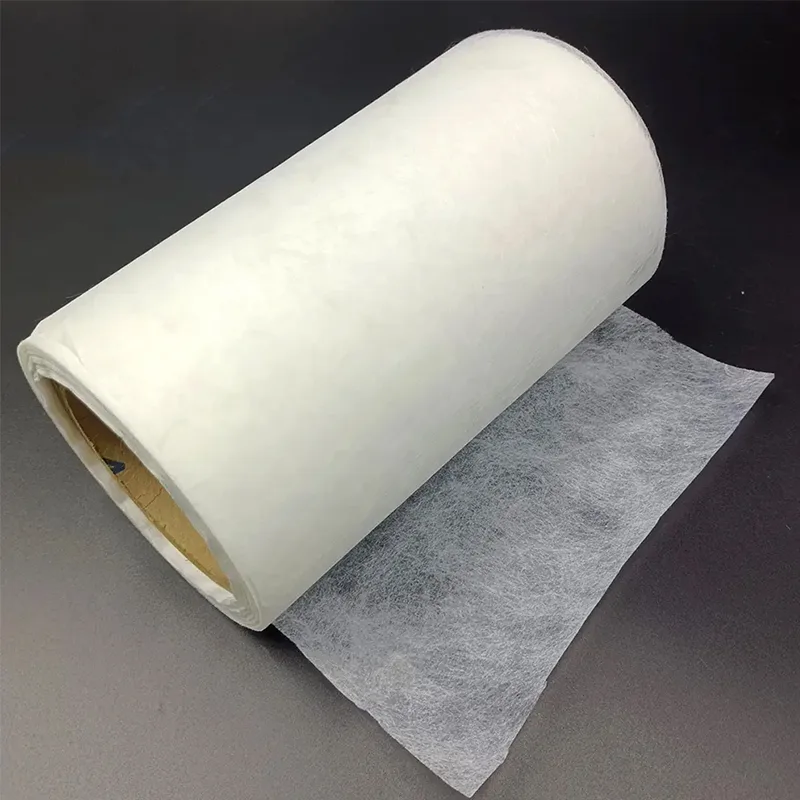

Our fiberglass mats are available in bulk quantities with weights between 10 g/m² and 1300 g/m², with additional custom weights and widths available to suit your packaging needs. Worried about shipping? Rest assured that our wholesale fiberglass mats are wrapped in waterproof plastic and packaged in crash-resistant cartons or wooden boxes. Whether retail or wholesale, our custom options ensure your brand stands out. Enhance your product line with our premium fiberglass mats and leave a lasting impression on your customers.

Different Types of Fiberglass Mat

NQ Fiberglass has produced a wide range of fiberglass felt for over 16 years, including continuous fiber felt, chopped fiber felt, fiberglass surface tissue paper, fiberglass needle felt, and fiberglass composite felt. We also offer customization based on your specifications, such as weight, length, width, coating, and packaging. This allows you to avoid the hassle of contacting multiple suppliers to meet your needs.

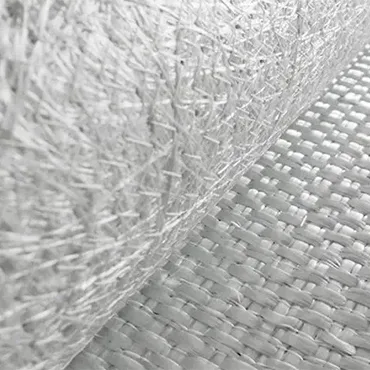

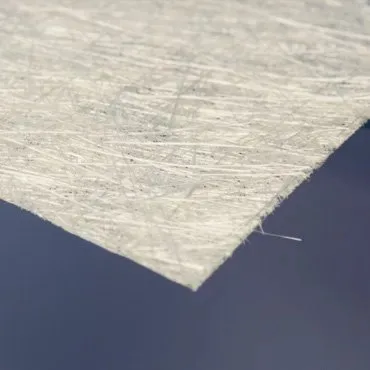

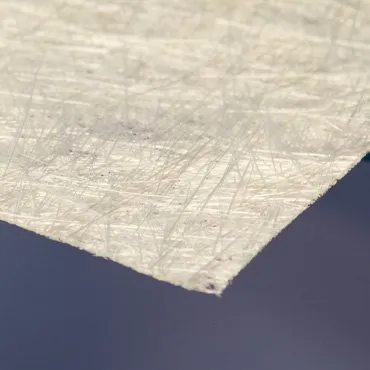

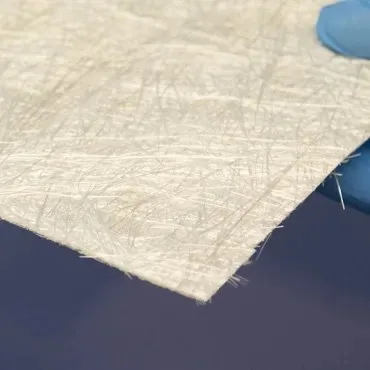

Continuous Filament Mat

Continuous filament felt is made from filament yarn and features a nonwoven structure containing an insoluble adhesive. It can be used in both non-filled and filled resin systems and is compatible with unsaturated polyester, epoxy, and polyamine resins.

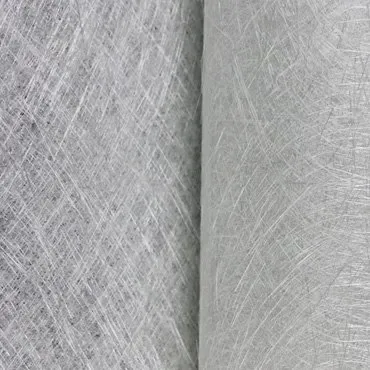

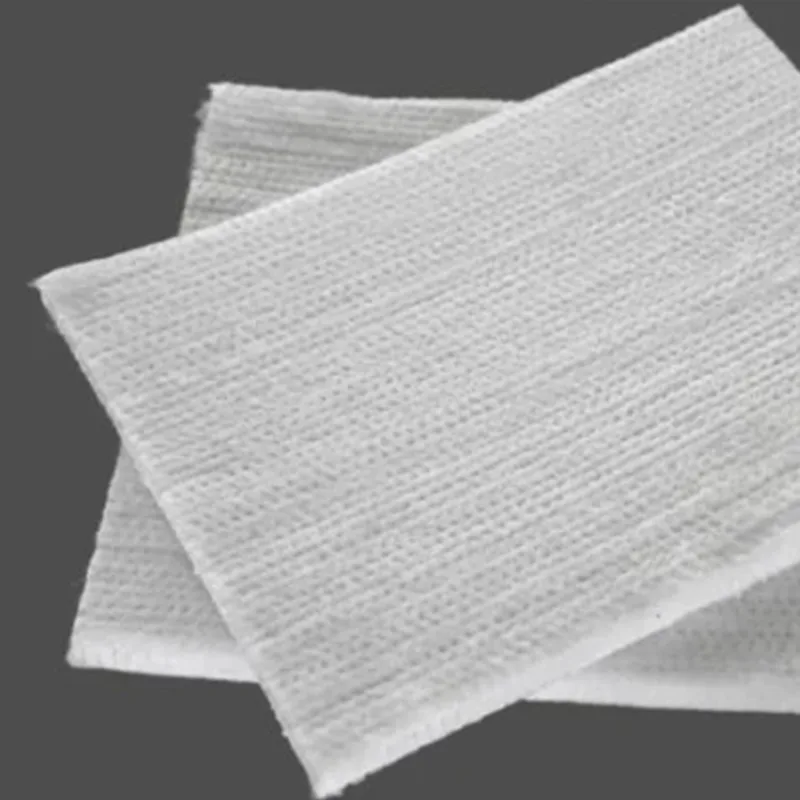

Chopped Strand Mat

Chopped felt is made from glass fiber strands bonded with powder or emulsion adhesive. It is primarily used for processing and manufacturing fiberglass products through hand lamination, fiber winding, and molding techniques.

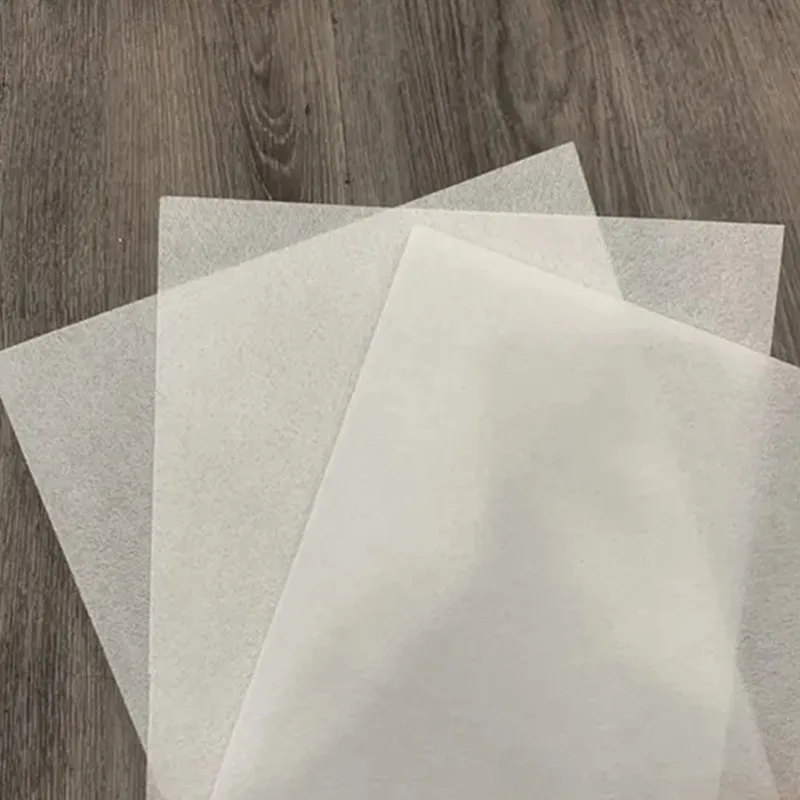

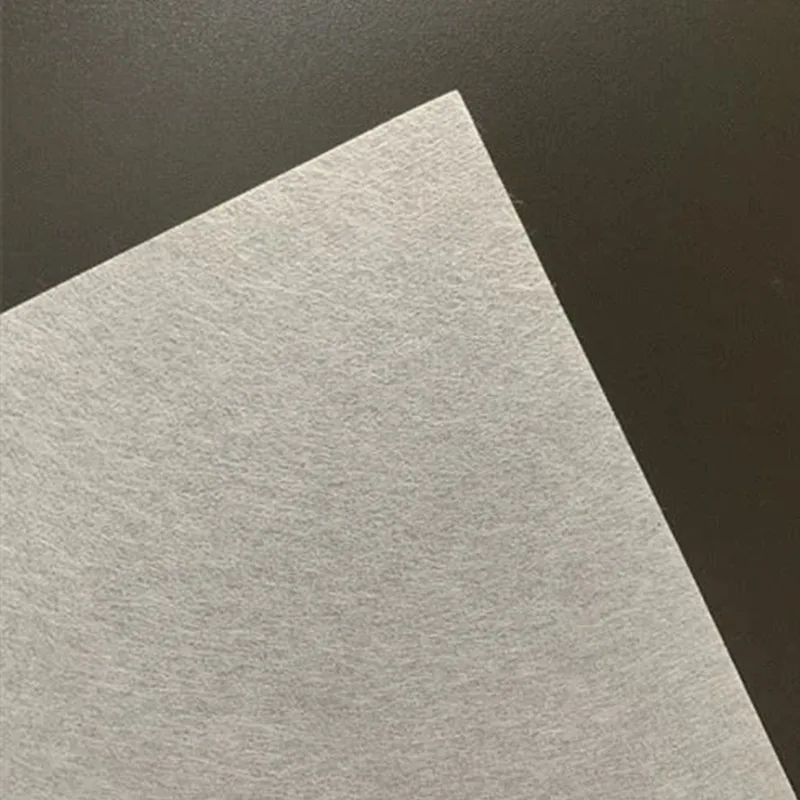

Fibreglass Surface Tissue

Glass fiber surface paper is primarily used on the surfaces of fiberglass products. It features uniform dispersion, a flat surface, and low adhesive content and promotes quick resin infiltration and strong mold adhesion. This product significantly enhances the surface’s corrosion, pressure, and leak resistance while also offering a long service life.

Fiberglass Needle Mat

Glass fiber needled felt is ideal for insulating various heating elements in pipelines due to its microporous and insulating properties. Additionally, it serves as a muffler and dust collector for gasoline engines in automobiles and motorcycles, thanks to its filtering and sound-absorbing capabilities. This material is widely used for sound insulation, moisture-proofing, fire prevention, and more.

Fiberglass Combo Mat

Fiberglass composite pads are typically made from fiberglass yarn woven in specific directions or stitched together with other fiberglass fabrics to achieve particular purposes. Depending on the application, they may prioritize softness or strength. The range includes no-twist combination pads, sandwich combination pads, stitch-knitted combination pads, fluffy filter pads, and needled combination pads.

Boost Your Business With Custom Fiberglass Mat

NQ provides comprehensive fiberglass mat industry solutions. Our high-quality fiberglass mat guarantees the monitoring and quality inspection of the entire process, from raw materials to production to shipment. Ensure that our professional-grade fiberglass mat enhances your brand.

Personalización del color

We offer various color options, including black, white, yellow, orange, blue, metallic colors like gold and silver, and various vibrant, unique colors. We can customize colors to meet your specific needs and project preferences. Please feel free to contact us if you have any requirements.

Binder Customization

Short-cut chopped strands generally come in two bonding materials: emulsion and powder. Both have advantages. Emulsion-bonded chopped strands appear smoother and have a better shape, with fewer loose fibers, making them recommended by manufacturers. They are typically used in large products with fewer contours. On the other hand, powder-bonded chopped strands can disperse during cutting and are more suitable for complex structures like molds.

Personalización de envases

We use heat-shrinkable film for inner packaging, PE bags for individual rolls, and cardboard boxes or plastic woven bags for outer packaging. This ensures moisture protection and safeguards the products during transportation and storage. Additionally, we offer customized packaging options to meet our customers’ specific needs.

Fiber Glass Mat Specifications

Our fiberglass mat is available in various specifications to match your project requirements. Please contact us for specific parameters to ensure optimal performance and meet your unique needs.

Lugar de origen | JiangSu, China |

Mat Type | Stitch Bonding Chop Mat |

Fiberglass Type | E-glass, S-glass, C-glass and AR-glass, etc |

Softness | Soft |

Marca | NQ |

Area Weight | 250±13g/㎡,300±20g/㎡,450±20g/㎡,625±25g/㎡,900±30g/㎡,1250±40g/㎡,etc |

Binder Type | Powder/Emulsion |

Compatible Resins | UP, VE, EP, PF resins |

Tensile Strength | 90-250 N |

Moistrue Content | ≤0.2% |

40FT Container | 20 Tons |

20FT Container | 10 Tons |

Widths | 50-3200mm |

Binder Content | 2-13% |

Item Name | Glass fiber Chopped Strands matting, roofing glass fiber mat,Glass fiber knitted combo mat,Glass fiber woven roving combo mat,Glass fiber surface mat,Glass fiber fabric prepreg |

Color | white,black ,gray , etc. |

Aplicación | Building waterproof, insulation and structural reinforcement; Help cars, ships lightweight; Industrial filtration, insulation materials; Promote plant growth; Enhanced material performance |

Producto | Alfombrillas de fibra de vidrio |

Especificación | 100/120/150/225/300/380/450/600/900gsm,Customized |

Anchura del rollo | 1040/1250/1270/1500mm,Customized |

Peso del rollo | 30-40kg,Personalizado |

NQ Fiberglass Mat Production Process

1. Cut The Raw Yarn

We use high-quality raw fiberglass materials from the Monolith Group, the world’s largest fiberglass yarn manufacturer, including Saint-Gobain, which is 20% stronger than standard fiberglass yarn.

2. Binder Application

Powders include polyester resin powder, epoxy resin powder, etc., and emulsions include polyacrylate emulsion, butadiene emulsion, etc. You can choose according to your needs.

3.Roll Treatment

The roller pressing equipment with a fully automatic integrated detection system dramatically improves production efficiency and product quality. Different types of glass fiber mats can be matched with suitable equipment according to your specific needs and processing characteristics.

4. Drying Treatment

An oven is used to dry out excess moisture and bond the glass fibers together. By carefully controlling temperature and time, the humidity can be precisely evaporated while minimizing the risk of thermal damage to the material.

5. Dry Pruning

Once the mat has cured, we utilize state-of-the-art trimming equipment to trim it to size and remove any irregular edges or excess material. Ensure the cut.

6.Packaging Treatment

A thorough quality inspection is then carried out at the end to check for defects such as uneven thickness, delamination, or foreign matter. Once the felt meets quality standards, it is packaged and prepared for shipment.

SF

Almacén y fábrica

Ingresos anuales totales

Trabajador cualificado

Asóciese con NQ para llevar su proyecto al éxito

Calidad superior: We have 35 production lines, using high-quality fiberglass raw materials and passing multiple quality inspection processes to ensure that each roll of fiberglass blanket meets international standards.

Precio competitivo: With our strong production capacity and raw material procurement advantages, we can provide cost-effective products to help you reduce production costs while maintaining high quality.

Totalmente personalizable: We provide comprehensive customization services and can adjust specifications, thickness, density, etc., according to your specific needs to ensure that the needs of different application scenarios are perfectly met.

Certificado

The Advantage Of The Fiberglass Mat

As a senior purchasing manager in the construction industry, I recognize the importance of quality materials for project success. Since partnering with this fiberglass mat manufacturer, I’ve gained confidence in their products. Made from premium raw materials, their mats are durable, weather-resistant, and stable in extreme conditions. The consistent quality across batches reduces risks and uncertainties. Additionally, their products offer great value, helping us save on procurement costs and reallocate resources effectively.

William Baker

Empresario

In automotive manufacturing, material choice impacts performance, safety, and durability. The fiberglass mats from this manufacturer have exceeded our expectations. Their strength, toughness, and stability are industry-leading, ensuring excellent performance in complex environments. Their competitive pricing helps us manage costs without compromising quality. Additionally, their after-sales service and technical support are top-notch, resolving issues quickly. I’m delighted with this partnership and look forward to continuing it.

Oliver Bennett

Empresario

Shipbuilding demands high-performance materials, and this manufacturer’s fiberglass mats meet our needs perfectly. Their mats offer excellent fire and waterproof properties, protecting ship structures from damage. They are lightweight yet strong, reducing the ship’s overall weight and improving efficiency. Their competitive pricing helps manage procurement costs while ensuring quality. Additionally, they provide tailored solutions and emphasize strong customer collaboration. I’m delighted with this partnership and look forward to continuing our work together.

Samuel Carlson

Empresario

The Advantage Of The Fiberglass Mat

Our expertise in fiberglass blanket manufacturing has made us one of China’s most trusted fiberglass blanket manufacturers. With our advanced production facilities, we provide high-quality fiberglass blankets to customers worldwide and meet the needs of various industrial applications. Our fiberglass blanket products can help customers effectively reduce costs and meet the needs of bulk purchases. The fiberglass blankets we provide have the following advantages:

Rapid Wet Out

The resin will quickly penetrate the material. By optimizing its surface energy, pore structure, and other performance parameters, we can enhance the penetration speed and uniformity of the resin, thereby improving the overall performance and reliability of the composite.

Good Uniformity

Fiberglass pads can be held closely to objects. Uniform fiber distribution, pore structure, and consistent resin penetration provide a tight fit to the object, allowing for more efficient processing.

Non-corrosive

Glass fiber mats are corrosion-resistant, chemically stable, and can effectively resist the erosion of various corrosive media, ensuring that your equipment or structure can operate reliably for a long time, even in harsh environments.

Thermal and Mold Resistance

The glass fiber mat boasts impressive heat insulation and mildew resistance properties. It effectively blocks heat conduction, delivering an excellent thermal insulation effect. Furthermore, it resists mold growth, maintaining a dry and clean condition, thereby extending its service life.

Compatible

Glass fiber felt is compatible with various resin materials, including polyester, vinyl ester, and epoxy resin. This compatibility allows it to form composite materials with high strength, modulus, corrosion resistance, and wear resistance. As a result, it offers more options for your projects.

Easy to Handle

Using or installing fiberglass mats is straightforward. Their excellent flexibility allows them to be easily adapted for installation on complex shapes and surfaces without complicated preconditioning or cutting, simplifying the process.

Fiberglass Mat By GSM or OZ

GSM (grams per square meter) or OZ (ounces per square foot) is an essential parameter for selecting fiberglass mats. There are 1.5 oz, 2 oz, 100g, 300g, 450g, 600g, etc. It directly determines the thickness of the glass fiber in the mat. Choose the appropriate fiberglass mat in combination with the application field. Generally, low GSM has better wettability and uniformity, while high GSM has thicker layers and higher strength.

1.5 oz Fiberglass Mat

Weight: 1.5 ounces per square foot

A 1.5 oz fiberglass mat means that each square yard weighs 1.5 ounces (about 42.5 grams). This material consists of non-woven glass fibers and is commonly used to reinforce structures and provide additional strength and durability. It is often combined with resins or other reinforcing materials and is widely used to manufacture composite materials.

2 oz Fiberqlass Mat

Weight: 2 ounces per square foot

2 oz fiberglass mat is sold in continuous 50″ wide rolls and is suitable for use as a reinforcement material or surface treatment material. Its thinness makes it unsuitable for structural repairs as it does not provide sufficient strength; however, you can achieve the desired thickness and strength by stacking multiple layers if necessary.

100g Fibreglass Matting

Weight:100g per square meter

100g fiberglass mat is usually used with resin, with fast wet, good transparency, and apparent effect after drying. It is relatively thick and is one of the thickest of all surface materials. The standard width is 1270mm, which is widely used on various occasions that require enhanced strength and durability.

450g Fibreglass Matting

Weight: 450g per square meter

The 450g fiberglass mat has fast moisture absorption, allowing it to quickly interact with water and promote adhesive dissolution, helping accelerate the curing process. It is widely used in industries such as construction, automotive, and shipbuilding to enhance the strength and stability of composite materials.

600g fibreglass Matting

Weight: 600g per square meter

The 600g fiberglass mat provides uniform strength in all directions, ensuring consistent performance of composite materials under different load directions. It is suitable for high-strength and high-durability applications in construction, automotive, and shipbuilding industries.

Chopped Strand Mat By GSM or OZ

GSM (grams per square meter) or OZ (ounces per square yard) is essential when selecting Chopped Strand Mat. The choice should be based on the specific application. Lower GSM/OZ offers better penetration but may not cover the underlying surface adequately. On the other hand, higher GSM/OZ ensures improved stability and stiffness.

1.5 oz Chopped Fiberglass Mat

Weight: 1.5 ounces per square foot

The 1.5-ounce chopped fiberglass mat is commonly used with epoxy resin to increase the thickness of parts or molds quickly. It can be used as an interlayer material or on its own, and workers often tear the fibers during application to enhance the bonding effect.

2 oz Chopped Fiberglass Mat

Weight: 2 ounces per square foot

The 2 oz chopped mat is made from medium-fine fibers and chopped glass filaments bonded with polyester powder or emulsion. When resin is applied, it quickly dissolves the binder and absorbs the resin, becoming transparent and durable after drying. It is suitable for enhancing the strength and thickness of composite materials.

3 oz Chopped Fiberglass Mat

Weight: 3 ounces per square foot

The 3 oz chopped fiberglass mat is bonded with adhesive and comes in powder or emulsion forms. It is suitable for quickly increasing thickness but is not recommended for thick layers due to lower durability than higher GSM materials. It performs better on curved surfaces or small corners and is easy to cut or tear, making it convenient.

CSM 300 Fiberglass Mat

Weight: 300g per square meter

CSM 300 fiberglass mat is one of the most popular products, with bundles of glass filaments bonded by powder or emulsion. When the polyester resin is applied, the binder dissolves, making the mat soft enough to conform to different contours and surfaces closely. However, it is most effective and economical when used to build up the body and thickness, providing enhanced strength.

CSM 450 Fiberglass Mat

Weight: 450g per square meter

CSM 450 fiberglass mat is made from alkali-free chopped glass fibers bonded with powder or emulsion, typically used with resin to dissolve the binder and soften the mat. It is especially suitable for hand lay-up and winding processes and is widely used in building structures, providing high strength and durability.

Fiberglass Mat By Different Applications

Due to its strength and durability, fiberglass mat is used in various industries. In construction, it’s used to reinforce concrete and create composite materials. In the automotive y marine industries, it’s used to make lightweight, strong parts like body panels and boat hulls. It’s also used in wind energy to reinforce blades, electronics to insulate, and industrial applications to make molds and durable parts.

Flooring Tissue

The S-FLM series mat is mainly used as a soft plastic flooring and wallpaper substrate. It features a smooth surface, no deformation, vibrant colors, and easy installation, making it an ideal material for residential flooring decoration. After further processing, it can be made into various colored laminates, making it perfect for decorating high-end hotels and stores.

Carpet Tissue

The carpet felt series is mainly used as the substrate for carpet tiles. Carpet tiles made from fiberglass felt have a firm appearance, do not shrink or deform and are ideal for indoor floor decoration.

PCB(Printed Circuit Board )Tissue

PCB electronic felt is a key material for CEM-3 production. Our E-glass electronic products, developed in China, are used in CEM-3 steel plates. Tests show our fiberglass paper meets or exceeds import standards, has superior heat resistance, and is widely used in high-frequency and LED applications.

Insulation Tissue

Insulation felt is a high-quality material made from short-cut glass fibers using a wet-forming process. It has good fiber distribution, uniform thickness, high-temperature resistance, and low thermal conductivity, ensuring excellent insulation. The product is easy to install, energy-efficient, cost-effective, and suitable for waterproofing, underground pipelines, and interior and exterior applications.

Battery separator tissue

The separator felt is primarily used as the base material for lead-acid battery separators. The composite separators with S-BM offer good vibration resistance and mechanical strength, resulting in batteries with strong starting power and a longer lifespan.

Roofing Tissue/Pipe Tissue

S-RM series felt is used to make modified asphalt waterproofing membranes and glass fiber shingles, which can improve weather resistance and impermeability and extend service life. It is suitable for roofing and insulation layers. S-PM series felt is used for underground pipeline waterproofing, has excellent resistance to environmental factors, extends pipeline life, and reduces maintenance costs.

Application Of Glass Fiber Mat

Fiberglass mat is a versatile material used in construction for reinforcement, automotive manufacturing for lightweight parts, shipbuilding for durable, corrosion-resistant components, and sports equipment for strength and performance. It’s also widely used for electrical insulation due to its heat and resistance.

Chemical Engineering

In chemical engineering, fiberglass mat is used for lining pipes, containers, and tanks, offering corrosion and heat resistance, and coatings and reinforcement in reactors.

- Espesor: 1.5-4mm

- Densidad: 250-600g/m²

- High-temperature resistance: 300℃

- Corrosion resistance: Strong

Industria de la construcción

In construction, fiberglass mat reinforces plastering, walls, and flooring, offering strength, durability, and crack resistance. It also enhances roofing stability.

- Espesor: 1.5-4mm

- Densidad: 250-600g/m²

- High-temperature resistance: 200-300℃

- Corrosion resistance: Excellent

Sports And Leisure

In sports and leisure, fiberglass mats are used in equipment like surfboards, skateboards, and bicycles for their light weight, strength, and durability, improving performance and resistance to wear.

- Espesor: 1.5-3mm

- Densidad: 200-400g/m²

- High-temperature resistance: 150-250℃

- Corrosion resistance: Good

Electronic And Electrical Field

In the electronics and electrical field, fiberglass mat is used for insulation in components like transformers and circuit boards, offering high-temperature resistance and electrical insulation.

- Espesor: 0.8-2mm

- Densidad: 200-400g/m²

- High-temperature resistance: 180-250℃

- Corrosion resistance: Excellent

Preguntas frecuentes

A continuación encontrará algunas preguntas frecuentes sobre envíos y MOQ. Si tiene alguna pregunta, no dude en ponerse en contacto con nosotros. Contacto.

¿Cuál es su MOQ?

Nuestro MOQ es generalmente 1x20ft contenedor.pero aceptamos menor cantidad para su pedido de prueba. Por favor no dude en informarnos su plan para

de compra, le ofreceremos el precio correspondiente a su qty. Y esperamos que su aumentaría su qty de la orden después de que usted compruebe nuestro

calidad del producto y conozca nuestros servicios.

¿Cuál es el puerto de embarque?

Enviamos la mercancía a través del puerto de Shanghai.

¿Cuántos colores hay disponibles?

Podemos hacer el color de encargo cuando alcance nuestro qty de MOQ.

Nuestros colores habituales son blanco, amarillo, verde, azul, naranja, rojo, etc.

¿Qué formato de archivo necesitan si quiero hacer mi propio diseño?

Para imprimir el diseño de la etiqueta, necesitamos un archivo AI o PDF para configurar la placa de impresión.

¿Cuál es su plazo de entrega?

El plazo de entrega es de unos 20~30 días después de recibir el depósito.

¿Cuál es su tiempo de muestreo?

Normalmente tardamos entre 7 y 10 días en hacer las muestras.

¿Qué forma de envío está disponible?

Por mar hasta el puerto designado.

¿Qué forma de pago es viable?

1. L/C irrevocable, efectivo, PayPal, tarjeta de crédito y transferencias de dinero T/T.

2.30% T/T depósito por adelantado, 70% saldo antes del envío después de la presentación de la carga lista.

3.L/C ( LC Irrevocable a la vista)

Si necesita un tamaño personalizado, como peso en gramos y tamaño de malla, etc., o un logotipo privado, no dude en consultarnos.

Fiberglass Mat FAQ

What is a fiberglass mat used for?

A fiberglass mat is a non-woven fabric made by interweaving fiberglass filaments into a mesh structure, which are bonded together through chemical adhesives or mechanical means.

Its main uses include:

- Reinforcement of Composite Materials: Fiberglass mat is commonly used to reinforce composite materials like unsaturated polyester and epoxy resin, enhancing their strength and rigidity.

- Hand Lay-Up Process: A fiberglass mat is used to strengthen resin-based composite materials in hand lay-up molding.

- Pultrusion Process: A fiberglass mat is used in the extrusion process to enhance the longitudinal and transverse strength of products and prevent cracking.

- Thermal Insulation: Fiberglass mat has excellent thermal insulation properties and is widely used in construction, shipbuilding, automotive, and other fields for thermal insulation.

- Filtration Material: Fiberglass mat is used in air and liquid filters due to its good filtration performance.

- Sound Insulation and Noise Reduction: Fiberglass mat is used in the automotive industry for sound insulation, noise absorption, vibration reduction, and fire resistance.

- Roof Waterproofing: Fiberglass mat is the substrate used for roofing waterproofing membranes due to its excellent properties.

In conclusion, fiberglass mats are widely used in various fields, such as composite material reinforcement, thermal insulation, filtration, sound insulation, and roof waterproofing.

Which is better, fiberglass mat or cloth?

Here’s a comparison table of fiberglass mat vs fiberglass cloth:

| Característica | Estera de fibra de vidrio | Tela de fibra de vidrio |

|---|---|---|

| Manufacturing Process | Made from randomly bonded short glass fibers. | Made from woven continuous glass fibers. |

| Strength | Generally lower tensile strength compared to cloth. | Higher tensile strength due to its woven structure. |

| Flexibility | More flexible, adapts easily to irregular shapes. | Less flexible, best for flat or structured surfaces. |

| Acabado superficial | Typically smoother, suitable for smooth surfaces. | Rougher texture, better for structural applications. |

| Peso | Heavier, used in thicker applications. | Lighter, more suitable for weight-sensitive applications. |

| Durability | Less durable in terms of tensile strength. | More durable, especially in high-stress applications. |

| Applications | Common in boat building, insulation, and surface repairs. | Used in aerospace, automotive, and high-performance applications. |

| Cost | Generally cheaper than fiberglass cloth. | More expensive due to higher strength and precision. |

This comparison helps in deciding which material to use depending on the specific requirements, like strength, flexibility, weight, and cost.

What is fiberglass cloth used for?

Fiberglass cloth is made from woven glass fibers. It is known for its lightweight, high strength, corrosion resistance, and high temperature resistance. It is widely used in multiple fields.

Main Uses:

- Composite Material Reinforcement: Fiberglass cloth is commonly used to reinforce composite materials, such as fiberglass, enhancing their mechanical strength and durability.

- Electrical Insulation: Fiberglass cloth is widely used in electronic products, such as circuit boards, due to its excellent electrical insulation properties.

- Industria de la construcción: In the construction field, fiberglass cloth is used for wall reinforcement, exterior wall insulation, roofing waterproofing, and enhancing materials like cement, plastic, asphalt, marble, and mosaic.

- Shipbuilding: Fiberglass cloth is widely used in hand lay-up molding for ship hulls, storage tanks, cooling towers, vehicles, and other applications.

- Industria del automóvil: Fiberglass cloth is used to manufacture car body parts, enhancing their strength and safety.

- Aeroespacial: Fiberglass cloth is used in the manufacturing of aircraft and spacecraft. It provides lightweight and high-strength properties that improve fuel efficiency and load capacity.

- Industria química: Fiberglass cloth is used to protect storage tanks and pipelines from corrosion, extending the service life of equipment.

- Electronics: Fiberglass cloth is used in electronic components for insulation and shielding, protecting components from external electromagnetic interference.

In conclusion, fiberglass cloth’s excellent performance makes it important in many fields, including composite material reinforcement, electrical insulation, construction, shipbuilding, automotive, aerospace, chemical, and electronics.

Does fiberglass mat go bad?

Fiberglass mat is a non-woven fabric made from glass fibers, known for its excellent high-temperature resistance, corrosion resistance, and insulation properties.

Storage Conditions:

Fiberglass mats should be stored in a dry, well-ventilated environment, away from direct sunlight and high humidity, to prevent the material from absorbing moisture or aging.

Lifespan:

With proper storage, fiberglass mat typically has a long lifespan.

Considerations:

Prolonged exposure to high temperatures, humidity, or chemically corrosive environments may degrade the performance of fiberglass mats.

Therefore, it’s recommended that it be inspected for appearance and performance before use to ensure it meets the required standards.

How many layers of fiberglass mat to use?

The number of layers of fiberglass mat to use depends on the specific application and the desired strength. Here are some general recommendations for different fields:

Boat Building:

Fiberglass mat is commonly used in the base layers of a boat’s hull to provide strength, while fiberglass cloth is used for the surface layer for a smoother finish. The number of layers depends on the design requirements and the desired strength.

Roofing:

The number of fiberglass mat layers in roofing applications depends on the roof area and the expected usage. One layer of 450g/m² fiberglass mat is typically recommended for roofs without foot traffic. For roofs with foot traffic, one layer of 600g/m² fiberglass mat or two layers of 450g/m² fiberglass mat are recommended.

General Recommendation:

Determining the number of layers when using fiberglass mats is essential based on the specific application and design requirements. Typically, a base layer of fiberglass mat provides strength, while the surface layer uses fiberglass cloth for a smoother finish. The number of layers in roofing depends on the area and intended use.

Please note that these recommendations are general guidelines. The number of layers should be adjusted according to specific project needs and design criteria.

Can you use epoxy on fiberglass mat?

Epoxy can be used on fiberglass mats. It is a significant polymer material primarily composed of epoxy resin and hardener. Epoxy exhibits excellent characteristics such as corrosion resistance, heat resistance, vibration resistance, water resistance, and strong adhesive properties. These properties make epoxy widely applicable in various fields, including construction, artificial molding, compression molding, electronics, automotive, marine, aerospace, and more.

When applied to a fiberglass mat, epoxy can enhance the mat’s strength, durability, and stability. The epoxy resin can penetrate between the fibers of the mat, forming a strong adhesive layer that improves the overall performance of the mat. Additionally, epoxy’s chemical and weather resistance can protect the fiberglass mat from environmental factors such as moisture and corrosion.

In practical applications, when treating a fiberglass mat with epoxy, the following points should be noted:

- Select the appropriate epoxy and hardener: Ensure that the chosen epoxy and hardener are compatible with the fiberglass mat and can meet the required performance specifications.

- Proper mixing ratio: Follow the manufacturer’s instructions to correctly mix the epoxy and hardener to ensure optimal cured performance.

- Uniform application: Apply the mixed epoxy evenly onto the fiberglass mat, avoiding bubbles or uncovered areas.

- Curing conditions: To achieve the best curing effect, ensure that the epoxy cures under appropriate conditions, such as temperature, humidity, and time.

- Safety precautions: Epoxy may release harmful gases during the curing process, so it should be handled in a well-ventilated environment, and appropriate personal protective equipment should be worn.

Essentially, epoxy can be used on fiberglass mats to enhance their performance and service life. During application, attention should be paid to selecting the appropriate epoxy and hardener, proper mixing ratio, uniform application, curing conditions, and safety precautions.

Which is better, fiberglass mat or cloth?

Regarding the question of which is better, fiberglass mat or fiberglass cloth, there is no absolute answer as they each have different characteristics and advantages that suit different application scenarios.

FeatureFiberglass MatFiberglass Cloth

Material Made of chopped strands of glass fibers, randomly oriented. Made of woven glass fibers arranged in a structured pattern.

Strength Provides moderate strength but less than fiberglass cloth. Offers higher strength due to the woven structure.

Flexibility: It is more rigid and suitable for flat or slightly curved surfaces. It is more flexible and ideal for tight curves and complex shapes.

Peso Heavier compared to cloth of the same thickness. Lighter than mat for the same thickness.

Wet-Out Quality: It may not wet out as quickly or clearly with epoxy; it requires more resin. It wets out well with epoxy, providing a more precise finish.

Durability Generally durable but may have slightly lower strength. It is more durable and long-lasting due to the woven structure.

Applications Ideal for basic reinforcement, hulls, and areas with minimal flex. Used for high-strength applications such as automotive and aerospace.

Cost Usually less expensive. Generally, it is more costly due to the woven fibers.

Ease of Utilice: It is easier to work with for more extensive, flat surfaces. Requires more precision and skill, especially for curves.

Finish: Less smooth finish, often requires sanding. Smooth and finer finish, ideal for a clean surface.

Estera de fibra de vidrio

Characteristics and Advantages:

- Flexibility: Fiberglass mats generally have good flexibility, making them easy to handle and install, incredibly when filling irregular surfaces or gaps.

- Moisture Absorption: Some fiberglass mats, after special treatment, may have good moisture absorption properties, which can enhance the material’s performance in specific applications.

- Cost-Effectiveness: Compared to certain types of fiberglass cloth, fiberglass mats may offer better cost advantages, especially for large-scale applications.

- Reinforcement: When used as a base layer for coatings, putties, gypsum, and other materials, fiberglass mats can significantly improve surface strength and durability and prevent cracking.

Tela de fibra de vidrio

Characteristics and Advantages:

- High Strength: Fiberglass cloth typically has high tensile and bending strengths and can withstand significant forces, making it suitable for high-strength support applications.

- Resistencia a la corrosión: It exhibits good resistance to most chemical media and can be used long-term in acidic or alkaline environments.

- Heat Resistance: It has excellent high-temperature performance and can be used for extended periods in high-temperature environments.

- Insulation Properties: It is an excellent insulating material with good electrical and thermal insulation properties.

- Versatility: Fiberglass cloth comes in various weaving patterns and specifications, such as plain weave, twill weave, and bidirectional weaves, catering to different industry needs.

Application Scenario Comparison

- Industria de la construcción: Fiberglass mats are often used for wall insulation and surface reinforcement, while fiberglass cloth is more suitable for reinforcing building structures, roof repairs, and other high-strength support applications.

- Industria aeroespacial: Both may be used in the manufacture and repair of aircraft, rockets, and other aerospace vehicles, but the specific choice depends on the required performance and design specifications.

- Industria del automóvil: Fiberglass cloth is more commonly used to manufacture and repair automotive parts, such as bodies and engine covers.

Conclusion

In summary, fiberglass mats and fiberglass cloth each have their own merits, and the choice of which is better depends on the specific application scenario and requirements. Fiberglass mats may be more suitable when flexibility, cost-effectiveness, or specific moisture absorption properties are needed. On the other hand, fiberglass cloth may excel when high strength, corrosion resistance, heat resistance, or insulation properties are required. Therefore, one should consider the actual needs and application environment when choosing.

How strong is a fiberglass mat?

There is no absolute answer to the question of which is better, fiberglass mat or fiberglass cloth, as they each have different characteristics and advantages that suit different application scenarios.

FeatureFiberglass MatFiberglass Cloth

Material Made of chopped strands of glass fibers, randomly oriented. Made of woven glass fibers arranged in a structured pattern.

Strength Provides moderate strength but less than fiberglass cloth. Offers higher strength due to the woven structure.

Flexibility: It is more rigid and suitable for flat or slightly curved surfaces. It is more flexible and ideal for tight curves and complex shapes.

Peso Heavier compared to cloth of the same thickness. Lighter than mat for the same thickness.

Wet-Out Quality: Epoxy may not wet out as quickly or clearly; it requires more resin. However, epoxy wets out well, providing a more precise finish.

Durability Generally durable but may have slightly lower strength. It is more durable and long-lasting due to the woven structure.

Applications Ideal for basic reinforcement, hulls, and areas with minimal flex. Used for high-strength applications such as automotive and aerospace.

Cost Usually less expensive. Generally, it is more costly due to the woven fibers.

Ease of Use: It is easier to work with for more extensive, flat surfaces. Requires more precision and skill, especially for curves.

Finish: Less smooth finish, often requires sanding. Smooth and finer finish, ideal for a clean surface.

Estera de fibra de vidrio

Characteristics and Advantages:

- Flexibility: Fiberglass mats generally have good flexibility, making them easy to handle and install. This makes them incredibly useful when filling irregular surfaces or gaps.

- Moisture Absorption: Some fiberglass mats, after special treatment, may have good moisture absorption properties, which can enhance the material’s performance in specific applications.

- Cost-Effectiveness: Compared to certain types of fiberglass cloth, fiberglass mats may offer better cost advantages, especially for large-scale applications.

- Reinforcement: Fiberglass mats can significantly improve surface strength and durability and prevent cracking when used as a base layer for coatings, putties, gypsum, and other materials.

Tela de fibra de vidrio

Characteristics and Advantages:

- High Strength: Fiberglass cloth typically has high tensile and bending strengths and can withstand significant forces, making it suitable for high-strength support applications.

- Resistencia a la corrosión: It exhibits good resistance to most chemical media and can be used long-term in acidic or alkaline environments.

- Heat Resistance: It has excellent high-temperature performance and can be used for extended periods in high-temperature environments.

- Insulation Properties: It is an excellent insulating material with good electrical and thermal insulation properties.

- Versatility: Fiberglass cloth comes in various weaving patterns and specifications, such as plain weave, twill weave, and bidirectional weaves, catering to different industry needs.

Application Scenario Comparison

- Industria de la construcción: Fiberglass mats are often used for wall insulation and surface reinforcement, while fiberglass cloth is more suitable for reinforcing building structures, roof repairs, and other high-strength support applications.

- Industria aeroespacial: Both may be used in the manufacture and repair of aircraft, rockets, and other aerospace vehicles, but the specific choice depends on the required performance and design specifications.

- Industria del automóvil: Fiberglass cloth is commonly used to manufacture and repair automotive parts, such as bodies and engine covers.

Conclusion

In summary, fiberglass mats and fiberglass cloth each have their own merits, and the choice of which is better depends on the specific application scenario and requirements. Fiberglass mats may be more suitable when flexibility, cost-effectiveness, or specific moisture absorption properties are needed. On the other hand, fiberglass cloth may excel when high strength, corrosion resistance, heat resistance, or insulation properties are required. Therefore, one should consider the actual needs and application environment when choosing.

Is fibreglass matting waterproof?

Fiberglass matting is not inherently waterproof, but it can become waterproof when combined with waterproof resin or other coatings. Here’s how it works:

- Fiberglass Matting Characteristics:

- A fiberglass mat is made from chopped glass fibers bonded with a binder. While the matting does not naturally repel water, it is resistant to moisture and will not degrade or dissolve in the presence of water, unlike some other materials.

- Waterproofing with Resin:

- Fiberglass matting is typically used with a waterproof resin, such as epoxy resin, polyester resin, or vinyl ester resin, to make waterproof matting. The resin binds the fiberglass fibers together and fills the spaces between them, creating a waterproof barrier.

- Epoxy resin, in particular, is known for its excellent water resistance and is often used for applications that require waterproofing, such as in boat building, roofing, and waterproof coatings.

- Applications:

- When fiberglass matting is used with resin in applications like boat hulls, waterproof roofing, or waterproof barriers in construction, it forms a strong, durable, and waterproof layer that resists water infiltration.

- In roofing systems, fiberglass mat is often used as part of a multi-layer system, providing structural reinforcement and helping maintain a waterproof surface.

- Environmental Resistance:

- Fiberglass matting is highly resistant to moisture y water over time, as the glass fibers do not absorb water. However, the matting alone would not provide full waterproofing without proper resin treatment.

Conclusion:

Fiberglass matting is not waterproof by itself, but when combined with a suitable waterproof resin, it can become waterproof, making it ideal for applications where moisture and water resistance are crucial.

Why do people use fiberglass?

People use fiberglass for a wide range of applications due to its unique combination of properties that make it highly versatile. Here are the key reasons why fiberglass is widely used:

1. High Strength-to-Weight Ratio

- Fiberglass is lightweight but strong, making it ideal for applications where strength and weight are essential. It is more potent than many metals (like aluminum) and is much lighter, which is why it’s used in the automotive, aerospace, and marine industries.

2. Resistencia a la corrosión

- Fiberglass is highly resistant to chemical, moisture, and environmental corrosion. This makes it an excellent material for harsh environments, such as marine vessels, chemical tanksy construction (e.g., roofing, pipes).

3. Durability

- Fiberglass is durable and long-lasting. It can withstand extreme temperatures and physical wear, making it suitable for indoor and outdoor applications.

4. Insulation Properties

- Fiberglass is an excellent thermal and electrical insulator. It’s commonly used for insulation in buildings (e.g., fiberglass insulation batts), electrical components, and applications requiring resistance to temperature changes.

5. Flexibility and Molding Capabilities

- Fiberglass can be easily molded into complex shapes, making it highly versatile for various industries. It is often used in molding applications to create custom parts for the automotive, aerospace, and construction industries.

6. Lightweight and Cost-Effective

- Compared to metals like steel or aluminum, fiberglass is often more cost-effective and provides significant weight savings, a critical factor in many industries, such as automotive manufacturing y boat building.

7. Water Resistance

- Fiberglass is inherently water-resistant; it forms a strong, waterproof barrier when combined with resin. This makes it ideal for boat hulls, swimming poolsy waterproof coatings in construction.

8. Reinforcement Material

- Fiberglass is often used as a reinforcing material in composite structures. Combined with resins (like epoxy or polyester), it creates strong, durable composite materials used in aerospace, constructiony automotive manufacturing.

9. Fire Resistance

- Fiberglass is non-combustible and has excellent fire-resistant properties, making it an essential material for applications requiring fireproofing, such as construction, electrical systemsy protective gear.

10. Ease of Maintenance

- Products made with fiberglass are often easy to maintain, resistant to UV degradation, and do not require frequent replacements. This makes it ideal for outdoor equipment, automobilesy construction materials.

Summary:

Fiberglass is used for its strength, lightweight nature, corrosion resistance, durabilityy insulating properties. It is a key material in various industries, including construction, marine, automotive, aerospacey insulation.

What is fibreglass matting used for?

Fiberglass matting is a versatile material used in various applications due to its strength, durability, and resistance to environmental factors. Here are some common uses of fiberglass matting:

1. Boat Building and Marine Applications

- Fiberglass matting is commonly used in boat hulls y marine structures to provide strength and resistance to water. Combined with resin (such as polyester or epoxy), it forms a rigid, waterproof layer ideal for boat construction and repair.

2. Roofing and Waterproofing

- In roofing systems, fiberglass matting is used as a base layer in waterproofing membranes. It helps reinforce roofing systems, preventing leaks and ensuring long-lasting protection against moisture.

3. Fabricación de automóviles

- Fiberglass matting is used in automotive parts like body panels, fenders, and interior components. It provides strength and impact resistance while reducing weight, making it a key material in the automotive industry for creating durable, lightweight components.

4. Construction and Reinforcement

- Fiberglass matting is often used to reinforce materials such as concrete or plaster. It helps improve the structural integrity and durability of walls, ceilings, and floors, particularly in drywall applications or when reinforcing masonry walls.

5. Pipes and Tanks

- Used to reinforce pipes y storage tanks, fiberglass matting provides resistance to corrosion and impact. It’s commonly employed in industries where chemicals are transported or stored, such as chemical processing plants.

6. Swimming Pools

- In swimming pool construction y repairs, fiberglass matting is often applied as part of a multi-layer system to create a durable, water-resistant finish. It helps ensure that the pool structure is strong, resistant to cracking, and easy to maintain.

7. Wind Turbine Blades

- Fiberglass matting is used to manufacture wind turbine blades due to its strength-to-weight ratio, making it an ideal material for large, lightweight, yet strong structures that can withstand harsh weather conditions.

8. Insulation

- Fiberglass matting is often used in thermal and acoustic insulation applications. It can be found in buildings and vehicles as a material to reduce heat transfer and dampen sound, improving overall comfort and energy efficiency.

9. Waterproofing Fabrics

- Fiberglass matting is used as a reinforcing layer in waterproof fabrics y membranes, providing added durability for outdoor gear, such as tents, tarps, and protective covers.

10. Reinforced Plastic Composites

- Fiberglass matting is a key component in creating fiberglass-reinforced plastic composites. These composites are used in a wide range of applications, such as industrial tanks, pipes, bathtubsy countertops, due to their strength, resistance to chemicals, and ease of maintenance.

11. Fireproofing

- Fiberglass matting is sometimes used in fireproofing applications, as it is non-combustible and offers fire-resistant properties. It can be integrated into fire-resistant panels and insulation systems to protect buildings and infrastructure.

Summary:

Fiberglass matting is widely used in marine, automotive, construction, roofingy insulation industries due to its strength, water resistance, corrosion resistancey versatility. It is a critical material in products and applications that require reinforcement, durability, and protection from the elements.

Does fiberglass insulation lose R-value over time?

The R-value of fiberglass insulation does not significantly decrease over time under normal circumstances. The R-value is an essential metric for measuring the thermal insulation performance of a material, reflecting its ability to resist heat flow.

The R-value of fiberglass insulation is primarily determined by factors such as the material’s thickness, density, and fiber structure. These factors are established during the material’s manufacturing process and remain relatively stable during use without significant changes over time.

Sin embargo, it should be noted that if the fiberglass insulation is damaged during installation or use, such as being compressed, torn, or exposed to moisture, these factors may affect its insulation performance, decreasing the R-value. Additionally, if the material is exposed to extreme temperatures or humidity for prolonged periods, it may have a minor impact on its performance, but this impact is usually not significant enough to cause a substantial reduction in R-value.

To maintain the good performance of fiberglass insulation, the following points are recommended during use:

- Ensure that the material is not damaged during installation and that its original thickness and density are maintained.

- Avoid exposing the material to extreme temperatures or humidity for prolonged periods to minimize the impact on its performance.

- Regularly inspect the integrity and performance of the insulation system to identify and repair any potential issues promptly.

In summary, the R-value of fiberglass insulation does not significantly decrease over time under normal circumstances, but care should be taken to protect the material from damage and avoid exposing it to extreme environments that may affect its performance.

What happens if fibreglass resin gets wet?

Under normal circumstances, fiberglass insulation’s R-value rings to a composite material combining fily resin material; here, it is assumed to mean fiber material’s-ass-reinforced resin-based compete; the impact depends on the specific type of resin, the structure of the composite, and the duration of water exposure. Below are some possible scenarios:

- Resin Type:

- Unsaturated Polyester Resin: This resin type is relatively sensitive to moisture before curing. The presence of water can lead to incomplete curing reactions or the formation of bubbles, which can affect the strength and appearance of the composite.

- Epoxy Resin: Epoxy resin also has a particular sensitivity to moisture before curing, but it is generally less significant than that of unsaturated polyester resin. However, if the resin is still in a liquid state and uncured, the mixing of water can interfere with the curing process, resulting in incomplete curing, surface defects (such as cloudiness, white or hazy areas, ripples, waves, depressions, and spot marks), and reduced performance after curing.

- Thermosetting Resin: Once cured, most thermosetting resins (including fiberglass-reinforced resin-based composites) are highly resistant to moisture and will not be significantly affected by short-term exposure to water.

- Composite Structure:

- If water can penetrate between the composite’s internal layers, it may weaken the interlayer bonding and even cause delamination.

- Damage to the composite’s surface protective layer (such as paint or gel coat) may increase the risk of water penetration.

- Duration of Water Exposure:

- Short-term water exposure may only impact the composite’s surface, such as leaving water stains or damaging the protective layer.

- Long-term immersion in water may cause the resin matrix to absorb moisture and expand, leading to changes in the composite’s dimensions, reduced performance, and even structural damage.

- Subsequent Treatment:

- If the composite gets wet, it should be dried promptly to prevent the adverse effects of prolonged water retention.

- For already cured composites, if only the surface gets wet, its appearance and performance can usually be restored through cleaning and drying.

- If water has penetrated the composite interior, more complex repair measures may be required, such as locally replacing damaged parts or reinforcing the entire structure.

In summary, the impact of fiberglass resin getting wet depends on various factors, including the type of resin, the structure of the composite, the duration of water exposure, and subsequent treatment measures. In practical applications, appropriate protective and response measures should be taken based on specific situations to ensure the composite’s performance and service life.

What is the difference between roving and mat fiberglass?

The following is the English translation of the previous text:

Differences between Roving and Mat Fiberglass

1. Structural Differences

- Fiberglass Roving:

- Roving consists of continuous filament fiber bundles that are typically not woven or knitted but retain their original form, forming strands of fiber strips.

- Roving fibers usually have high strength and stiffness due to their composition of continuous filament fibers without interruption points.

- Estera de fibra de vidrio:

- Conversely, a mat is made from short-cut or continuous fibers that are randomly distributed, intertwined, and bonded (using powders or emulsion binders) into a sheet material.

- The fibers in the mat are arranged relatively chaotically, but this disorder gives the mat good flexibility and processability.

2. Application Areas

- Fiberglass Roving:

- Roving is mainly used in applications requiring high strength and stiffness, such as manufacturing reinforced plastics (e.g., glass-fiber-reinforced plastic), pultrusion, and filament winding processes.

- It is also commonly used to produce high-performance composite materials and structural components, such as wind turbine blades, ships, and automotive parts.

- Estera de fibra de vidrio:

- Due to its flexibility and processability, the mat is widely used in hand lay-up, spray-up, and continuous lamination processes.

- It is also frequently used in manufacturing various FRP (fiber-reinforced plastic) products, such as pipes, storage tanks, and building panels because it provides uniform fiber distribution and good resin penetration.

3. Performance Characteristics

- Fiberglass Roving:

- High strength and stiffness, capable of withstanding significant tensile and bending stresses.

- Good fiber directionality, with performance along the fiber direction being much better than that perpendicular to it.

- Estera de fibra de vidrio:

- Good flexibility, easy to handle, and shape.

- Uniform fiber distribution aids in uniform resin penetration and curing.

- Available in a range of thicknesses and weights to suit specific needs.

4. Packaging and Transportation

- Fiberglass Roving:

- Typically packaged in rolls or bundles, convenient for transportation and storage.

- Care is needed to prevent fiber breakage and contamination.

- Estera de fibra de vidrio:

- Mat is usually packaged in sheets or rolls and may require additional protective measures (such as plastic film wrapping) to prevent fiber shedding and moisture absorption.

- To avoid deformation and damage, it should be kept dry and flat during transportation.

In summary, roving and mat fiberglass differ significantly in structure, application, performance, packaging, and transportation. The choice between them depends on specific application requirements and process demands.