Estera de fibra de carbono

Características

Personalización del color

Ofrecemos una amplia gama de colores estándar, entre ellos negro clásico, gris discreto y rojos, azules, verdes, naranjas, morados, plateados, blancos y marrones vibrantes.

Los fabricantes de NQ tienen una excelente capacidad de personalización y pueden adaptar colores únicos para Carbon Fiber Mat a las necesidades específicas de sus clientes. Nuestro equipo técnico profesional utilizará la tecnología avanzada de teñido y recubrimiento para que coincida con precisión la muestra de color o muestra proporcionada por el cliente para asegurar que el color personalizado de fibra de carbono Mat es precisa, brillante y de larga duración.

Cantidad mínima de producto

Tenga en cuenta nuestro pedido mínimo de estera de fibra de carbono. Para diferentes especificaciones de estera de fibra de carbono, el MOQ es diferente. Para la estera modificada para requisitos particulares de la fibra de carbono, debido a diversos requisitos de personalización, el MOQ necesita ser confirmado según la situación real.

Personalización

Las fábricas de NQ pueden personalizar diferentes anchuras y longitudes según las necesidades del proyecto para garantizar un uso óptimo de los materiales.

También hay flexibilidad en el envasado, que puede personalizarse según los requisitos del cliente, incluidos materiales de envasado, etiquetas, impresión, etc., para satisfacer las necesidades de distintos proyectos.

Pedido grande o pequeño

Pida uno o miles de artículos a la vez. Nuestro almacén y nuestro sistema de envío flexible están disponibles para pedidos de última hora y con plazos ajustados.

MUESTRA GRATUITA ●DEVOLUCIONES GRATUITAS

*La personalización está siempre disponible, por favor marque su necesidad en el carro o simplemente póngase en contacto con nosotros.

Supervisión de proyectos

Seguimiento de pedidos de envío

Instrucciones de uso

Servicio de atención al cliente VIP

Garantía Intacta

Descripción

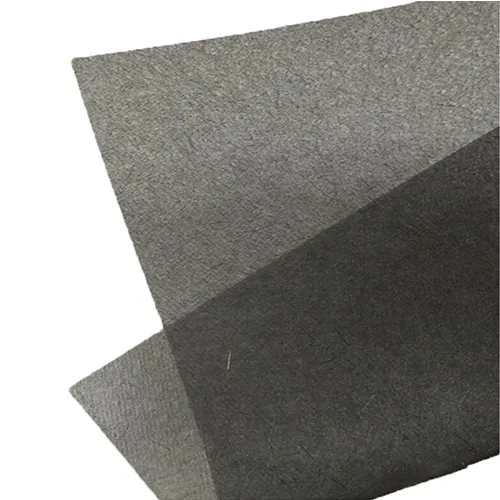

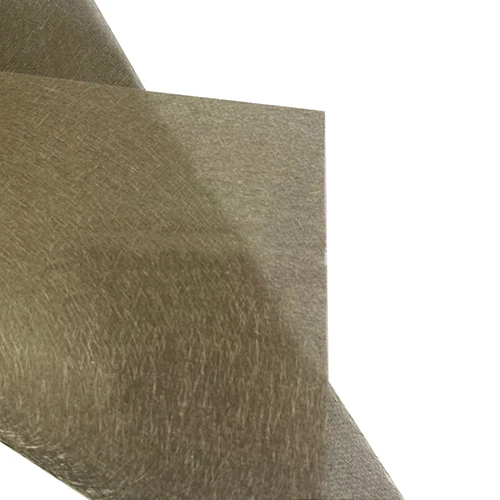

Carbon Fiber Chopped Strand Mat, abbreviated as CFCSM, is a non-woven mat product made of chopped carbon fiber strands. It is produced by cutting glass fibers into short lengths of approximately 50 millimeters, uniformly distributing them in a random direction, and bonding them into a mat-like form using polyester powder or polyester emulsion binder.

CFCSM boasts a range of excellent performance characteristics. Firstly, it has a uniform mass per unit area and is free from stains, impurities, and other defects, ensuring overall material quality. Secondly, CFCSM possesses moderate hardness and good flexibility, making it convenient to handle and use. Furthermore, it is easily and completely impregnable, resulting in fewer bubbles and excellent processability, providing favorable conditions for subsequent processing.

Additionally, CFCSM exhibits excellent mold-filling and mold-covering capabilities, suitable for shaping complex-shaped products. Its mechanical properties and chemical resistance are also outstanding, enabling CFCSM to maintain stable performance in various environments.

In summary, Carbon Fiber Chopped Strand Mat is a non-woven mat product made of chopped carbon fiber strands, characterized by its uniform mass per unit area, moderate hardness, good flexibility, easy impregnation, excellent processability, mold-filling and mold-covering capabilities, as well as superior mechanical properties and chemical resistance.

Función principal

Industria aeroespacial

- Wings and Tail Fins: CFCSM is used in the manufacture of wings and tail fins, effectively reducing weight and improving flight performance and fuel efficiency. Its high strength and lightweight properties make it an ideal material for aircraft.

- Aerospace Engines: CFCSM is utilized in the production of components for aerospace engines, enhancing their performance and reliability. Carbon fiber composites can withstand extreme conditions such as high temperatures and pressures, making them suitable for aerospace engine applications.

- Helicopters: The application of CFCSM significantly reduces the weight of helicopters, improving their performance and hovering capabilities. Additionally, its excellent damping and fatigue resistance properties enhance the safety and service life of helicopters.

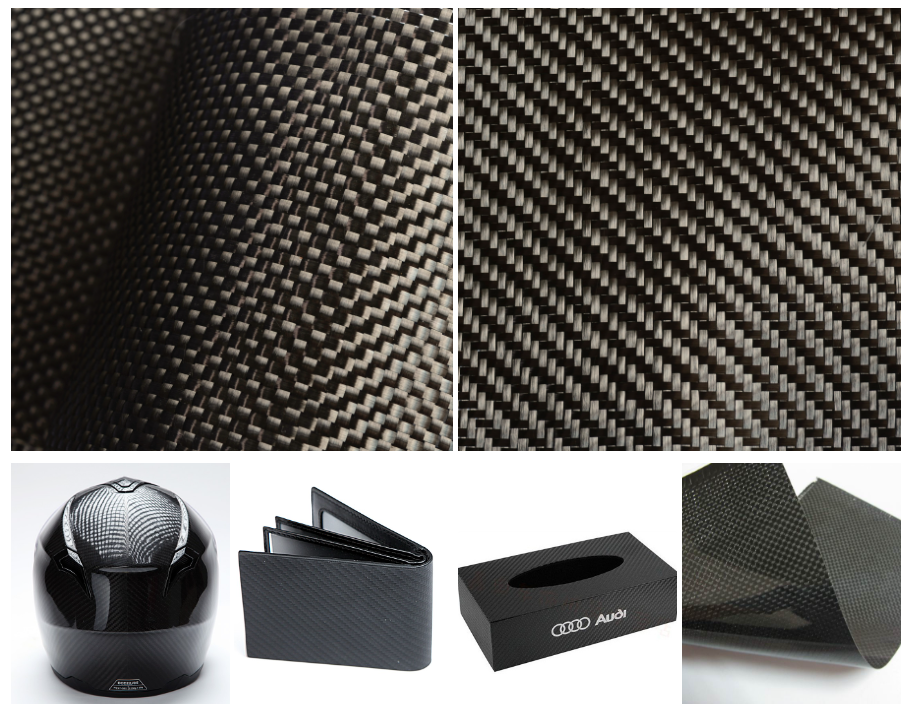

Sector del automóvil

- Vehicle Bodies and Components: CFCSM is used in the manufacture of automotive bodies and components, significantly reducing the overall vehicle weight and lowering fuel consumption. The lightweight advantage of carbon fiber composites makes vehicles more environmentally friendly and energy-efficient.

- Wheel Hubs: As an essential part of a vehicle, wheel hubs need to bear the weight of the entire vehicle and loads. CFCSM’s high strength and lightweight properties make it an ideal material for wheel hubs.

Medical Field

- X-ray Assisting Equipment: CFCSM is utilized in the production of bed panels, headrests, and radiation positioning plates for X-ray, CT, and ultrasound equipment. Its high X-ray transparency gives carbon fiber materials a unique advantage in the medical field.

- Bone Fixation Plates: CFCSM is used in the manufacture of bone fixation plates, helping reduce infection at the fracture site and promoting healing. Its elastic modulus is closer to human bone, providing a better treatment experience for patients.

Semiconductor Industry

- Carrier Transport: Carbon fibers in CFCSM can freely transport charge carriers, improving the performance of semiconductor devices.

- Enhancing Semiconductor Performance: Carbon fiber materials can increase the response speed and sensitivity of semiconductors, reduce power consumption, and accelerate the speed of transistors.

Especificación

Producto | Estera/fieltro/tejido/red de fibra de carbono |

Material | Fibra de carbono |

Peso | 10 g, 20 g, 30 g, 50 g, 60 g o personalizado |

Anchura | 125 cm o personalizado |

Longitud | 300 m/rollo |

Contenido en humedad | ≤0.5% |

Resistividad superficial | <10Ω |

Diámetro de la fibra | 6-7 um |

Contenido de la carpeta | 3%-20% |

Consulte a su especialista en venta al por mayor y embalaje de esteras de fibra de carbono NQ

Le ayudamos a evitar escollos y a ofrecer la calidad y el valor que necesita para la estera de fibra de carbono a tiempo y dentro del presupuesto.